The pilot eco-industrial park (EIP) project in Vietnam began in 2015 (pilot phase 2015-2019) and was implemented in four EIPs: Khanh Phu EIP, Gian Khau EIP in Ninh Binh, Hoa Khanh EIP in Da Nang, and Tra Noc 1&2 EIP in Can Tho.

|

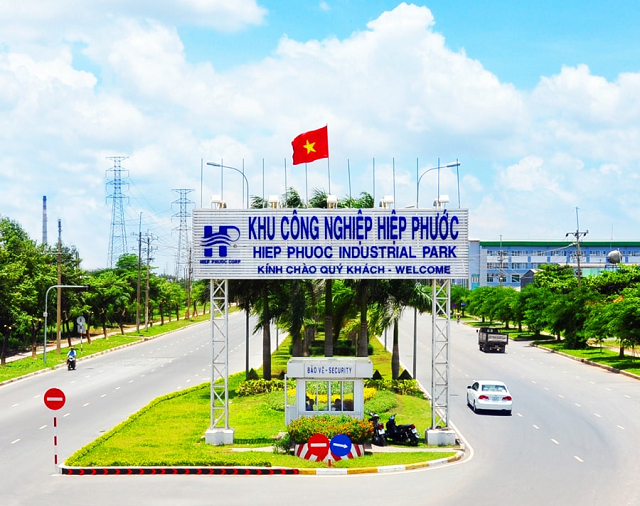

From 2020-2024, the Ministry of Planning and Investment collaborated with the United Nations Industrial Development Organization (UNIDO) to implement the project “Deploying Eco-Industrial Parks in Vietnam in line with the Global Eco-Industrial Park Program” with a total budget of over 1.8 million USD funded by the Swiss Federal Economic Cooperation (SECO), in five provinces/cities, including Ho Chi Minh City, Can Tho, Dong Nai, Da Nang, and Hai Phong, specifically in Hiep Phuoc EIP, Amata – Bien Hoa EIP, Dinh Vu (Deep C) EIP, Hoa Khanh EIP, and Tra Noc 1&2 EIP. The project aims to enhance the economic, environmental, and social efficiency of the industrial sector and incorporate regulations for developing EIP models into relevant mechanisms and policies. The Ministry of Planning and Investment and UNIDO have partnered to support the transition of existing industrial parks to EIPs with 603 cleaner production and resource efficiency (RECP) solutions, of which 88 businesses have implemented 217 solutions, contributing to saving 69.2 billion VND/year, equivalent to 2.9 million USD, by reducing energy, resource, and material consumption and cutting down 8,910 tons of CO2/year. |

To date, the Ministry of Planning and Investment continues to cooperate with the United Nations Industrial Development Organization (UNIDO) to expand the EIP model in Hai Phong, Dong Nai, and Ho Chi Minh City.

Currently, the EIP model has been institutionalized in legal documents and incorporated into several key national policies on sustainable production, consumption, green growth, and circular economic development in Vietnam and is being continuously improved.

The transition to the EIP model has initially brought about positive impacts on the economy, society, and the environment, while mobilizing significant resources from the private sector for green industrial solutions, ensuring energy security, sustainable development, and climate change mitigation.

“Transformation” through EIPs

Participating in the project “Deploying Eco-Industrial Parks in Vietnam in line with the Global Eco-Industrial Park Program” since November 2020, and being one of the EIPs undergoing transformation, Mr. Giang Ngoc Phuong – Deputy General Director of Hiep Phuoc Industrial Park JSC (UPCoM: HPI) shared that HPI started as a place for production units, residential areas, and had potential environmental pollution risks, so the city decided to relocate all potentially polluting production units.

According to Mr. Phuong, the first benefit of joining this project was to improve the lives of workers in the Hiep Phuoc Industrial Park. Additionally, the transformation will also help improve the environment by reducing energy and clean water consumption, decreasing emissions, promoting resource circulation, and helping businesses cut costs during production.

For businesses, coexisting in an EIP helps reduce production costs, lowers product prices, and enhances competitiveness.

Mr. Giang Ngoc Phuong – Deputy General Director of HPI

|

Symbiotic cooperation is a part of EIP recognition

In the past, cooperation between businesses in EIPs was based on common economic interests, but now symbiotic cooperation is part of the criteria for EIP and green EIP recognition.

Regarding the opportunities for symbiosis in Hiep Phuoc EIP, the Deputy General Director of HPI said that initially, the Company had about 60 models in the EIP, but after evaluating their feasibility and effectiveness, only seven models remained.

Some typical symbiotic models in Hiep Phuoc EIP include the transfer of heat from the Hiep Phuoc edible oil plant to a flour factory. In addition, Hiep Phuoc EIP has businesses producing cement and gypsum, and gypsum is a part of clinker for cement production. Therefore, when gypsum is produced, the byproduct from breakage during production is collected and sent to cement companies. “Although it is a byproduct and cannot be the finished product of this factory, it can be the raw material input for another factory and is considered symbiotic,” said Mr. Phuong about the benefits of symbiosis.

There are still many difficulties and challenges

Besides the benefits, the transition from a regular EIP to an eco-EIP or green EIP also faces many difficulties.

When joining the project, HPI had to establish and demonstrate detailed figures, requiring effective and transparent assessment. Therefore, continuous policy adjustments and dialogue and cooperation between the Government and businesses are necessary.

One of the initial difficulties was mobilizing businesses in the EIP to participate in the model because most businesses had no experience and did not understand the transition model, while there were many standards to meet international market requirements.

“Currently, over 20% of projects in Hiep Phuoc EIP intend to participate, mainly because these businesses themselves recognize the benefits for improving their operations. As a result, other businesses in the EIP are also following and developing accordingly. Anything that is good for production, costs, livelihood, or businesses will be supported,” said Mr. Phuong.

What is the appeal of industrial real estate in the Southern region for investors?