The Gold Mine at the End of the World

Nestled in the frigid wilderness of Russia’s northeastern Chukotka Autonomous Region, over 100 miles from the nearest town and accessible only by air or a 200-mile seasonal ice road that exists from November to April each year, lies Russia’s Kupol gold mine.

Geologically, the Kupol deposit is located within the Cretaceous Okhotsk-Chukotka Volcanic Belt, on the northwestern foothills of the Anadyr Range on the border between the Anadyr and Bilibino districts of the Chukotka Autonomous Okrug.

Getting there is hard, staying there is even harder. It’s one of the coldest, harshest places on Earth, famously known as the world’s “Pole of Cold” with brutal weather conditions, where temperatures can plummet to -50°C.

The ice road connecting Kupol to Pevek brings supplies to the camp. It has to be rebuilt each year from November to January. Photo: Elena Chernyshova

The 200-mile lifeline. Photo: Elena Chernyshova

At these “bone-chilling” temperatures, exposure can lead to hypothermia, frostbite, and heart attacks, making Russia’s Kupol gold mine one of the most challenging gold mines to operate in the world. It’s not a place where many people can – or would dare to – work.

But the “price” for enduring the frigid temperatures and icy isolation is the shiny allure of a precious metal that’s in high demand around the world: **gold. In fact, Kupol is the third-largest gold mine in Russia** (according to statistics from **Statista**).

Of course, getting the gold out requires extreme operations and living arrangements. So who – which company – has “struck gold” at Kupol?

Stock image.

Kupol’s gold-bearing veins were first discovered in the 1940s, buried beneath the permafrost of the Far North. But it wasn’t until over six decades later that advanced technology could be employed to extract the precious metal.

In 2005, Canada’s Kinross Gold acquired the Kupol mine. In 2007, the company began extracting gold there.

A year later, Kinross Gold announced a $705 million expansion plan to mine both gold and silver at Kupol. In addition to gold, the Kupol deposit also contains silver.

By late 2008, the Canadian company was producing gold on-site at the Kupol Mill, reducing the time and effort required to transport equipment and ore.

As a result, by the end of 2009, the Kupol mine reported producing 234,265 ounces of gold equivalent and 1,633,673 ounces of silver. By 2021, Kinross Gold had extracted 481.1 thousand ounces of gold (about 15 tons).

High-Tech Intervention

To extract all that gold, Kinross Gold had to overcome significant challenges in terms of manpower, resources, and equipment.

1. Building a Lifeline That Lasts Only 6 Months

Russian photographer Elena Chernyshova, who spent 10 days there to capture images of the gold mine at the end of the world, explains that Kinross Gold created a vital artery – a winter road – connecting Kupol to Pevek, an international port on the Arctic Ocean, over six months during the winter season.

The entire 200-mile road is marked with reflective poles. Notably, the roadway is cleared of snow continuously with the aid of hot-water jets.

During those six winter months, Kinross Gold sends 4,000 containers (carrying supplies, food, etc.) and 60,000 tons of fuel and lubricants from the port of Pevek to the Kupol mine to support gold mining operations.

When the ice melts, the road lifeline disappears, and people must travel by helicopter. Photo: Elena Chernyshova

When the ice melts in the spring and summer, the Kupol area can only be reached by helicopter – a 1.5-hour flight from Bilibino.

2. Building a Permanent Camp

In a region where temperatures can drop to -50 degrees Celsius, the equipment, machinery, and living and working conditions for thousands of people must be far from ordinary.

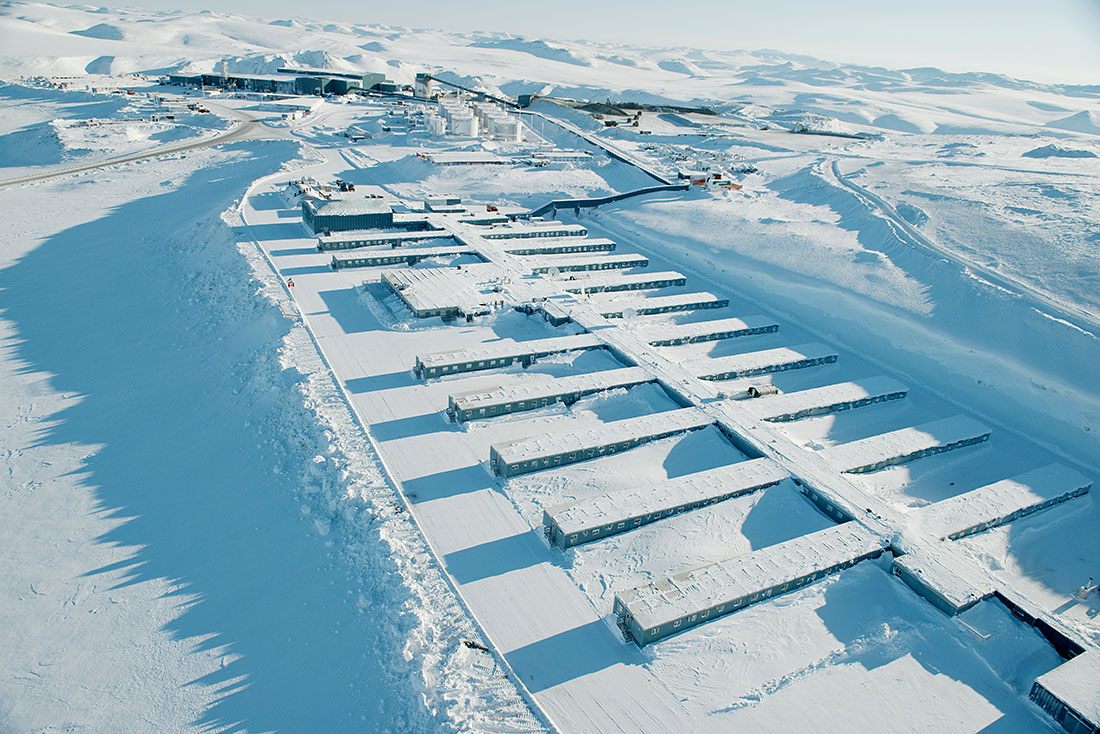

Aerial view of the Kupol mine and its permanent camp. Photo: Elena Chernyshova

Kinross Gold had to invest heavily to prevent machinery from freezing, batteries from draining rapidly, food from being frozen solid by the cold, and people’s skin from succumbing to the bone-chilling cold.

Since Kupol is hundreds of kilometers from the nearest town, Bilibino, the facility was designed as a ‘Permanent Camp.’

It was built to accommodate up to 656 people. The living quarters include VIP suites, single rooms, double rooms, and an area for senior staff. Due to the extreme weather conditions at Kupol, the camp also features recreational facilities for use after working hours, such as a recreation room, a gym, and a library.

Nearly 1,000 workers are employed at the mine, many of whom come from as far away as Brazil to work in the open-pit mine and underground mine. A 900-meter enclosed tunnel connects the camp to the mine, known as the “Arctic Passage.”

Workers stay on-site for two months, after which they have two months off. Workdays are 12 hours long, with no weekends.

3. Building the Kupol Mill

The Kupol Mill is