The path to effective green economic development is multifaceted and technology plays a crucial role. Smart manufacturing is a prominent approach to achieving green economy goals.

Smart production is one of the three pillars of a green economy, and it contributes to low-carbon, net-zero emissions, and resource efficiency. This pillar, focusing on industrial practices, is essential for Vietnam to meet its international commitments made at COP26. To achieve these goals, green economy processes must incorporate green production, exchange, circulation, and consumption. Businesses need to adopt green standards for inputs, outputs, production technology, machinery, and equipment.

In recent years, many Vietnamese manufacturing companies have invested in smart production to facilitate a green transition, aligning with domestic and international requirements. This presents both opportunities and challenges for Vietnamese businesses. Even companies at the pinnacle of success must innovate to avoid being left behind. It is imperative for businesses to transform their processes and products.

Enhancing Smart Production Capacity: Lessons from Rang Dong

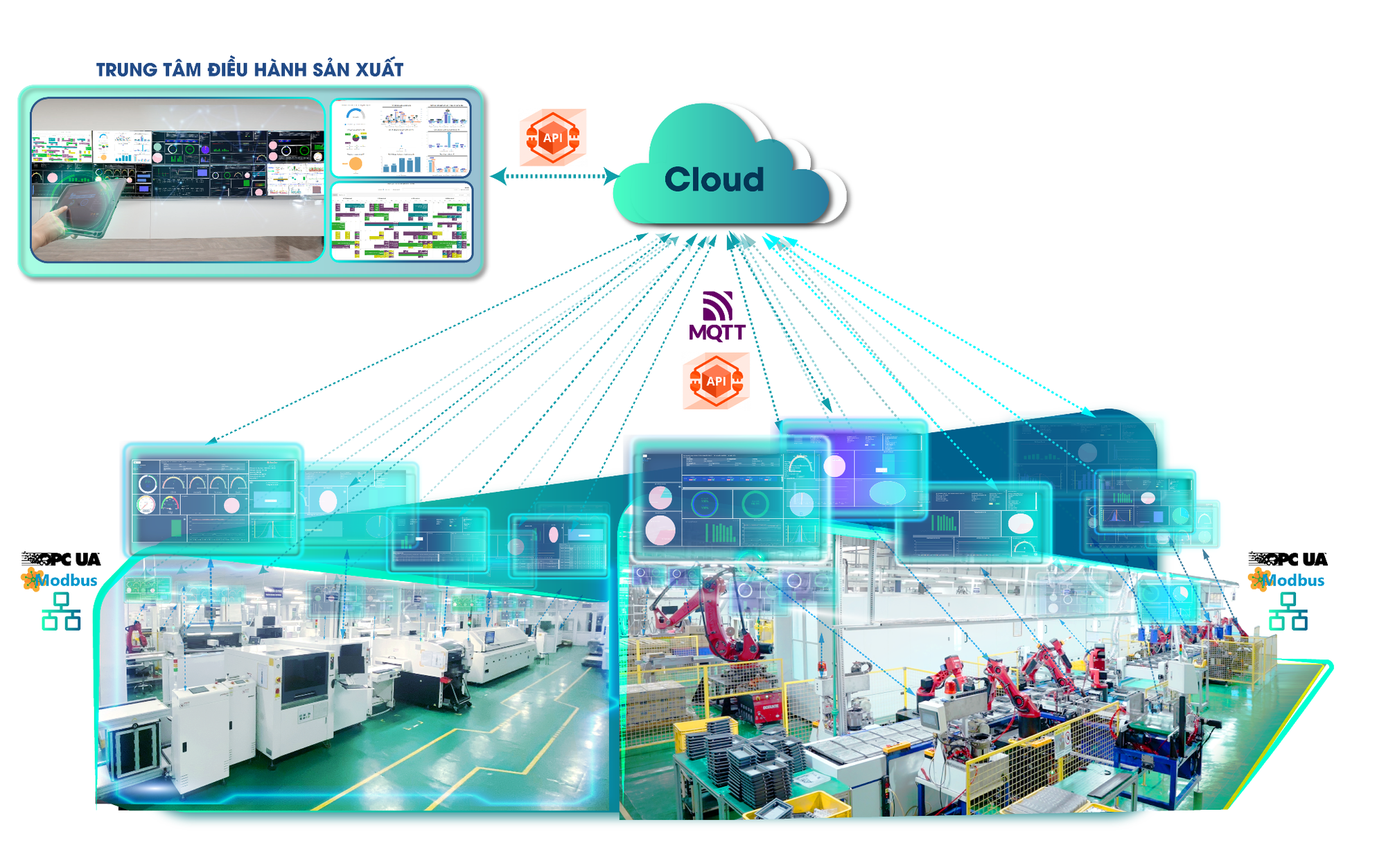

Rang Dong Light Source and Vacuum Flask Joint Stock Company is a traditional manufacturing enterprise that boldly embarked on a digital transformation journey with its 2020-2025 strategy and a vision towards 2030. Their goal is to become a high-tech and digital technology company. This strategy laid the foundation for Rang Dong to transition from traditional to flexible smart production.

Rang Dong’s RalliSmart Smart Home solution is one of three solutions in their 4.0 Product/Service Ecosystem.

Building on the initial success of their digital transformation strategy, Rang Dong established a flexible smart production model through partial automation and the implementation of “Make in Vietnam.” They developed pre-programmed robotic arms and connected fully automated assembly lines from start to finish. Using AI-powered AGVs and Fork Lifts, they efficiently transported materials from the beginning to the end of the production line. By streamlining and standardizing processes, they began digitizing, connecting, and utilizing production management software to meet the demands of large-batch production for customized orders. This ensured timely deliveries, reduced production costs, and optimized resources.

The flexible smart production model implemented at Rang Dong contributes to the growth of the factory.

Rang Dong also took the initiative to develop their own flexible smart production execution system (MES), giving them full control over the technology, from system development to programming. This allowed them to quickly address emerging needs without incurring additional costs. The operation of the MES system in production management created a unified information platform, facilitating smoother operations, more accurate planning, strict execution, and data-driven continuous improvement. These improvements contributed to economic efficiencies and sustainable environmental goals.

Materials are supplied at the beginning of the production line and transported to the end as finished products using AI-powered AGVs and Fork Lifts.

According to Rang Dong’s report, smart production has helped the company reduce production costs despite increases in material and borrowing costs. Labor productivity has increased by 30% for LED products (from 5.5 million to 7.5 million units per month) and by 37% for flask products (from 1.4 million to 1.9 million units per month).

Artistic lighting project for Hai Duong pedestrian street implemented by Rang Dong.

Emphasizing the role of science and technology in product development and commercialization, Mr. Nguyen Doan Ket, Deputy General Director of the company, attributed their success to knowledge accumulation, technology mastery, and external knowledge linkage through four centers: the Digital Transformation Consulting Center, the Lighting R&D Center, the Digital Technology R&D Center, and the Modern Business Models R&D Center. These centers facilitate knowledge transfer from the International Solid-State Lighting Alliance, strategic partners like Samsung, Seoul Semiconductor, and EverLight, leading Vietnamese technology corporations such as FPT, Viettel, and VNPT, as well as the Vietnam Academy of Science and Technology, research institutes, universities, and domestic and international experts.

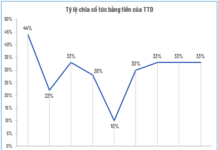

Rang Dong is also a strong investor in scientific and technological activities, allocating 22% of their post-tax profit for this purpose since 2022. Additionally, they are the largest shareholder in the BK Fund, a startup innovation investment fund.

Smart Home product line: https://rangdong.com.vn/category/nha-thong-minh

Smart Home solutions: https://rangdong.com.vn/nha-thong-minh-rang-dong.html

Lighting products: https://rangdong.com.vn/category/den-led-chieu-sang