Ford is taking steps to reduce production costs for its electric vehicles. In a recent memo to parts suppliers, the company requested collaboration to identify cost-cutting measures, signaling a strategic shift as the electric car market faces challenges.

Ford has taken a significant step by sending a memo to its electric vehicle parts suppliers, urging them to join forces in finding ways to reduce production costs. This move, as reported by Detroit Business, reflects the company’s recognition of the challenges faced by the electric car market and its commitment to making electric vehicles more affordable.

Traditional automakers like Ford are grappling with the financial realities of electric vehicle sales. According to reports, Ford is losing $100,000 on each electric car sold, double the loss from the previous year. This highlights the urgent need to address the cost structure and make electric vehicles a more sustainable proposition for both manufacturers and consumers.

Ford, one of the few automakers transparent about their electric vehicle business, reported a loss of $4.7 billion in this division last year and expects an additional $5.5 billion loss in 2024. CEO Jim Farley emphasized that the Model e division is a “burden” on the company’s overall performance. With intense competition from Tesla and a cautious consumer market, Ford is facing the dual challenge of keeping prices competitive and managing production costs.

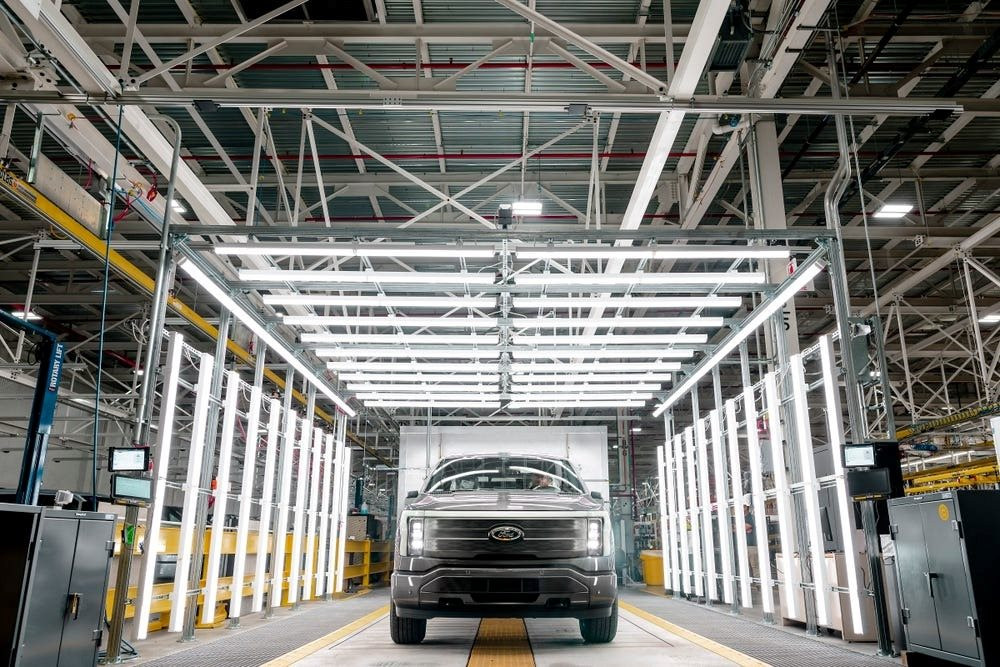

The memo sent to suppliers is a broad call to action, seeking cost-reduction proposals for current and future electric vehicle models, including the Mustang Mach-E, Ford F-150 Lightning, an unnamed pickup truck, and a large SUV. Liz Door, Ford’s supply chain director, emphasized the importance of this collaboration, stating, “We need your best ideas to drive cost reduction, even those previously considered and rejected. We have all invested a lot in this business, and we will all win or lose together.”

A Ford spokesperson, in a statement to Business Insider, affirmed the company’s commitment to providing affordable electric vehicles to customers and their goal of making the electric vehicle division profitable. They acknowledged the importance of supplier partnerships and their contribution to cost-cutting initiatives.

The current market dynamics present a challenge for automakers like Ford and Tesla, as they strive to meet the expectations of a pragmatic and cost-conscious customer base. However, this also creates an opportunity for innovation and collaboration across the industry to make electric vehicles more accessible and appealing to a wider audience.

In this evolving landscape, hybrid vehicles have gained traction, offering a bridge for consumers transitioning to electric cars. Ford and its competitors have taken note, refocusing their efforts on hybrid models and even reintroducing previously discontinued hybrid options. While this doesn’t diminish their commitment to electric vehicles, it does provide a pathway to profitability while they navigate the financial challenges of electric car production.

As Ford and other automakers work to improve the financial viability of their electric vehicle divisions, we can expect to see more cross-industry collaborations and innovative solutions to reduce production costs. The path to a more sustainable and widely adopted electric car market may be challenging, but with strategic initiatives and industry-wide cooperation, it is within reach.

Source: BI