Toyota Motor Corp. has posted record profits for the latest quarter, but a series of prior quality scandals is taking a toll on suppliers, who are facing increased costs and reduced output, according to Nikkei Asia.

“The production halt has imposed a financial burden on suppliers and dealers,” said Toyota’s accounting chief, Masahiro Yamamoto, acknowledging that while the certification scandals have had a minor impact on the group’s earnings, they are hurting parts makers.

Following the announcement of a record 1.3 trillion yen ($8.9 billion) quarterly profit, the Japanese automaker said it would increase investment in human resources and provide support to its suppliers. Similar to the first half of the year, Toyota will continue to cover the rising labor and energy costs of its suppliers in the second half of the fiscal year ending March next year.

Toyota’s operations in Japan have seen profit growth, largely due to the impact of a weak yen. However, the output of its luxury brand, Lexus, a cash cow for its Japanese plants, has decreased by 9% to 760,000 vehicles.

One of the hardest-hit members of the Toyota group is Daihatsu Motor, which has been forced to suspend production following irregularities in testing. At Toyota itself, irregularities were found in seven models, three of which have been halted. Others are awaiting assessment by authorities. The impact of the scandal could widen.

However, compared to the global financial crisis of 2008 and the widespread recalls of 2009 and 2010, Toyota’s income performance and production volume remain robust.

For the fiscal year, the company forecasts a profit of 4.3 trillion yen, a 20% decrease from the previous year, but still a significant improvement over previous downturns. In terms of production, output is expected to increase by 40% to 10 million vehicles for the fiscal year, compared to about 7 million in the year ended March 2010.

However, it is unclear if this target can be met as the certification scandals have led group members such as Aisin and Toyoda Gosei to cut production. A subsidiary of Futaba Industrial has shut down its production line.

“It is unclear whether the reduction can be made up for during the year,” said Fumiki Yazawa, director of Chuo Spring, a parts maker.

In response to the scandals, Toyota has lowered its daily production cap in Japan to 500 vehicles, down from 14,500 previously, citing the need to give production sites more time.

“In terms of profit, the truth is we want them to earn more,” said an executive at a parts maker in central Japan’s Aichi prefecture, Toyota’s home turf.

Toyota sources parts from a total of 60,000 companies in Japan, with annual transactions amounting to about 10 trillion yen. The production cuts will particularly affect small and medium-sized companies with limited product portfolios and production scales.

Moreover, as parts makers struggle with rising material and labor costs, the question arises as to whether they will increase prices. According to Teikoku Databank, the rate of Toyota’s first-tier suppliers that can pass on the full increase in material costs is 2.2%, lower than the average of 4.6% across all industries.

“The burden on first-tier suppliers is enormous,” said a representative of the research firm.

Previously, Japan’s Ministry of Land, Infrastructure, Transport and Tourism stated that Toyota and four other manufacturers had admitted to numerous errors in safety inspections. The company has halted the shipment and sale of the Corolla Fielder, Corolla Axio, and Yaris Cross models in Japan due to incomplete data used in tests for pedestrian and occupant protection.

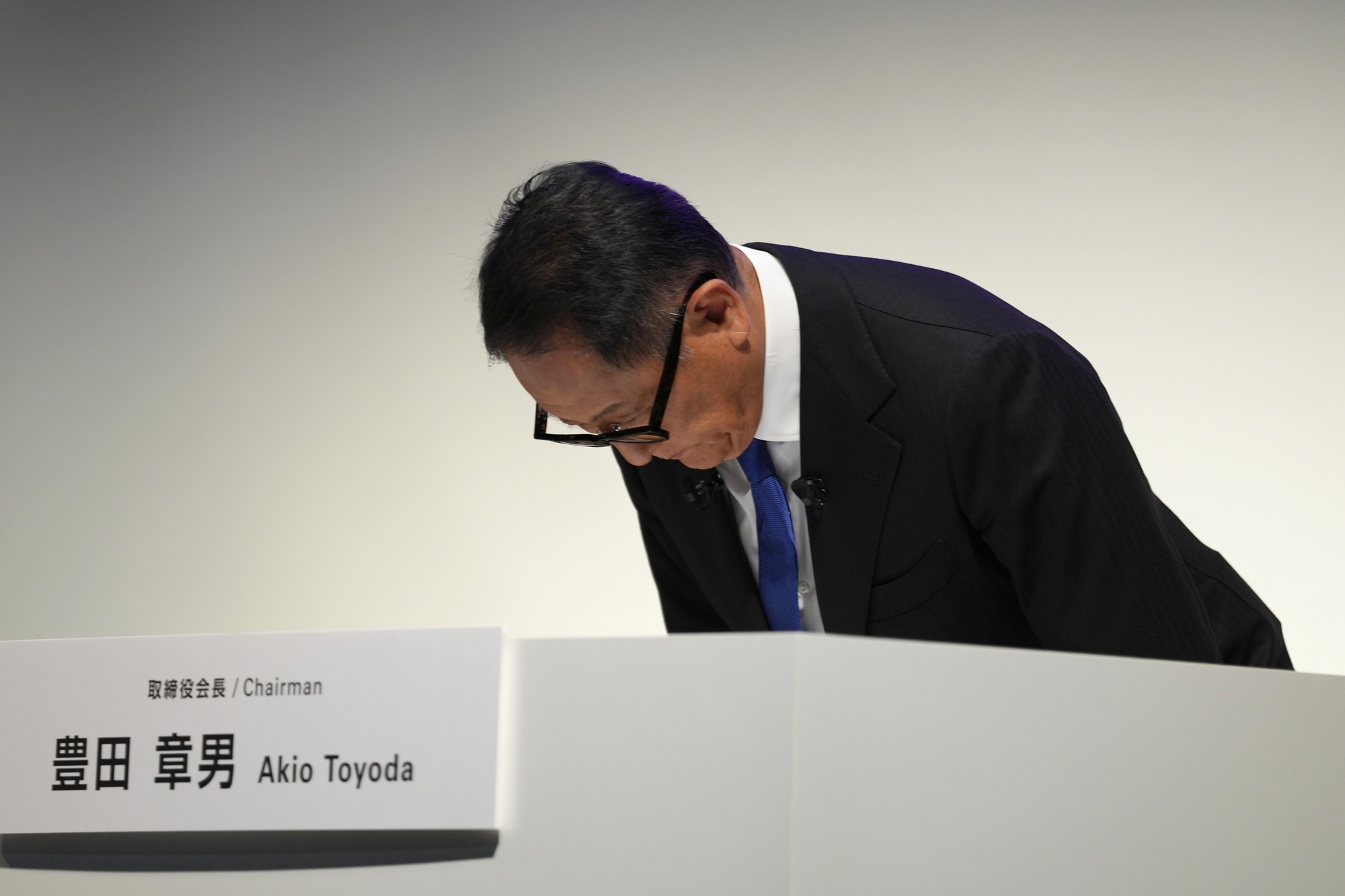

The ISS report stated: “Assessments from board members and the countermeasures announced by the company suggest a tendency to protect Toyota’s corporate culture, for which Mr. Toyoda should be held responsible.”

Similar irregularities to those at Toyota have been found at Honda Motor, Mazda Motor, and Suzuki Motor. This has prompted the ministry to request 85 companies in the industry, including automakers and equipment manufacturers, to investigate whether there are any irregularities in their model certification documents. The authorities view this as a matter of “eroding user trust and shaking the foundation of the nation’s auto certification system.”

According to the ministry, Toyota, Mazda, and Yamaha have all admitted to irregularities in their production processes. Some specific models have been ordered to halt shipments until they meet quality standards.

Atsushi Osanai, a professor at Waseda University, said, “I believe this is a result of the automakers’ overconfidence and naivete in thinking that deviating from current rules to some extent is not an issue.”

“The irregularities related to engines will cause anxiety and mistrust among engine makers. Japanese automakers should be cautious as their product strategies will also be affected,” Professor Osanai remarked.

Sources: Nikkei Asia, CNN