At the seminar “Overseas Vietnamese and the Development of Vietnam’s High Technology” within the framework of the Vietnamese Conference Overseas (VK4), overseas experts shared their experiences and contributed ideas on attracting investment and developing the semiconductor and AI industries in Vietnam.

Mr. Duong Minh Tien, a chip packaging expert from Samsung Electro-Mechanics, shared insights at the seminar. He highlighted the annual growth rate of the semiconductor chip industry from 2023 to 2027, expected to reach nearly 12% per year, with a projected scale of $1,000 billion by 2030. The main driver of this growth is AI chips, with an average growth rate of 36%/year, propelled by AI generations like ChatGPT.

Mr. Duong Minh Tien, Chip Packaging Expert from Samsung Electro-Mechanics

It is worth noting that during the pandemic and the early stages of the Russia-Ukraine conflict, the computer and phone chip segment suffered a significant decline, with expectations for a recovery to pre-pandemic levels by 2026.

Opportunities Will Arise in the Next Two Years

Mr. Tien particularly emphasized that by 2028, market demand will exceed production and supply capabilities, leading to a diversification of supply chains and expanded investments in the packaging and testing field. This presents a unique opportunity for Vietnam to “get a head start” in attracting investments for this wave of technological advancement.

Why does Vietnam have an advantage in this field, specifically in packaging and testing? Mr. Tien explained that in the semiconductor chip industry, there are two predominant models: fabless (focusing on research and design while outsourcing production, as seen with Nvidia and AMD) and IDM (integrating both design and production capabilities, exemplified by Intel and Samsung).

While the IDM model offers better control over the supply chain and reduces geopolitical risks, it has a significant drawback: an imbalance between design and production capabilities, hindering the swift release of advanced products.

In contrast, the fabless model adopted by Nvidia concentrates solely on research, claiming 60-70% of the product’s value, while outsourcing chip manufacturing (20-25%) and packaging and testing (10-13%). This model faces significant geopolitical risks due to its heavy reliance on TSMC in Taiwan, a sensitive region.

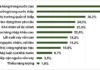

With Vietnam’s exceptional geopolitical stability, youthful population, and strong STEM capabilities, it emerges as a potential candidate to attract investments in the packaging and testing sector.

Sharing Mr. Tien’s sentiments, Professor Phan Manh Huong, a distinguished scholar in advanced sensor materials and technology from the University of South Florida, asserted that no single company can create a chip from start to finish. Instead, it relies on the interconnectedness of the global supply chain, and semiconductors are a global issue.

Professor Phan Manh Huong, University of South Florida

Regarding Vietnam’s chosen area of focus, Professor Huong believes that the country excels in packaging and testing, partly due to Intel’s presence in the country for almost 20 years. On the other hand, chip design is already dominated by developed countries and even India, making it a more challenging area to compete in.

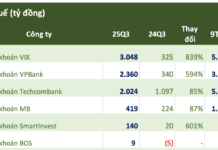

According to Mr. Tien, the packaging and testing field holds immense potential. From 2020 onwards, the governments of leading semiconductor countries like the US, EU, Japan, and South Korea have invested $150 billion to attract major chip manufacturing companies to build advanced factories. As these factories operate at full capacity to meet the surging demands post-2026, the advanced packaging sector for AI and servers will witness substantial investments.

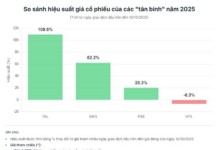

The packaging and testing field is projected to grow from $95 billion in 2022 to $143 billion in 2028, representing a 12% annual growth rate.

Evidencing Vietnam’s advantage in this field, the country has successfully attracted billions of dollars in investments from prominent corporations in chip packaging and substrate production, including Intel ($1.5 billion), Samsung ($2.3 billion), Amkor ($1.6 billion), and Hana Micron ($1 billion).

Regional Rival with Only 30% of Vietnam’s Population

According to the Samsung chip expert, Malaysia is Vietnam’s direct regional rival in attracting investments in the packaging and testing field. With a population of only 30 million, the Malaysian government has provided $5.3 billion in support, aiming to attract over $100 billion for the packaging industry. Additionally, they are targeting the training of 60,000 engineers for the semiconductor sector.

Delegates comprising overseas experts contributed ideas on strategies for the semiconductor industry’s development.

However, Vietnam holds a significant advantage in diplomacy, as both Malaysia and another prominent rival, Indonesia, have limited relations with Israel, a powerhouse in the semiconductor industry. By leveraging its strong relationships with major powers, traditional friends in the region and worldwide, and its multilateral foreign policy, Vietnam can create a competitive edge.

Additionally, Mr. Tien analyzed that Vietnam possesses another significant advantage over these two countries due to its favorable location near China’s “Silicon Valley” (Shenzhen) and its comprehensive strategic partnership with its neighboring country.

In terms of suggestions for Vietnam, Mr. Tien emphasized the need to reduce administrative procedures to facilitate easier investment attraction. He also recommended ensuring energy security, improving English proficiency among students, and prioritizing preparations for the upcoming wave of packaging, testing, and substrate investments.

Why did Amkor choose Vietnam as the world’s largest semiconductor production hub?

Bắc Ninh province boasts excellent infrastructure, meeting “special” requirements and cutting administrative procedures by one-third. Its infrastructure ranks among the best in Southeast Asia, which is one of the reasons why Amkor Corporation has chosen this province as the largest semiconductor production hub in the world.

Vietnam’s Advantages in the Multi-Billion Dollar Semiconductor Industry

With a young and abundant workforce, a deep understanding of technology, and a rapidly developing infrastructure, Vietnam has a competitive advantage in the semiconductor industry, particularly in the design phase. According to a survey by the Ministry of Planning and Investment, by 2030, Vietnam will have the capacity to train around 50,000 engineers in this field.