As a pioneer in drive and control technology worldwide, Bosch Rexroth has consistently strived to revolutionize industrial automation in Vietnam over the past 15 years. The company’s innovative solutions and applications are designed to facilitate seamless, efficient, and robust communication between machinery, propelling the transformation of Vietnam’s industry towards automation, intelligence, and enhanced productivity.

Mr. Huynh Phong Phu, Director of Factory Automation Business at Bosch Rexroth Vietnam, shared, “We believe that the Vietnamese market holds the key to unlocking significant opportunities for the Smart Factory model in Southeast Asia. As the country’s industry continues to flourish, we are committed to providing comprehensive solutions and advanced technology. Our goal is to optimize operations, enhance productivity, and help our customers maintain their competitive edge in the global market, becoming the most trusted partner in automation in Vietnam.”

ctrlX AUTOMATION: Breaking Boundaries

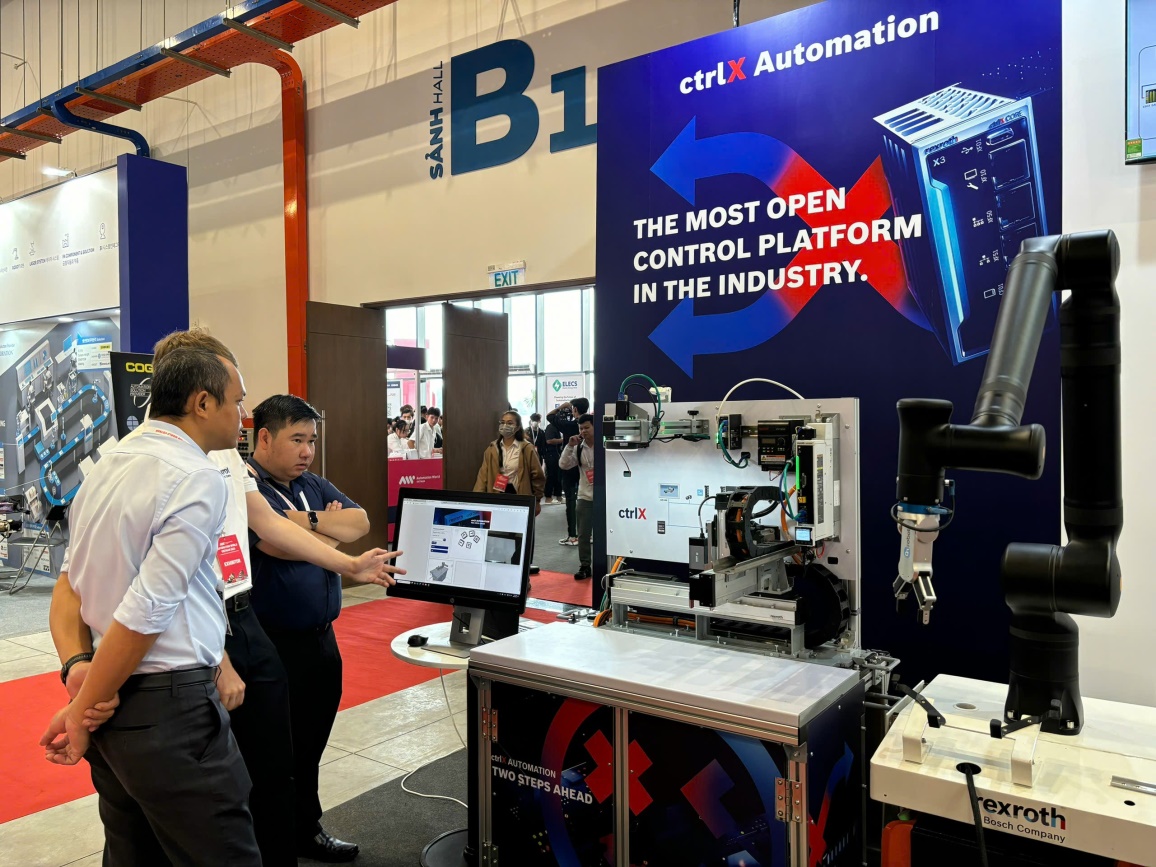

At Automation World Vietnam, Bosch Rexroth will offer a comprehensive overview of the breakthrough capabilities of ctrlX Automation, integrated within the factory automation ecosystem. This system provides all the components for a complete automation solution, from controllers to mechanical systems and robotics, catering to various fields such as Smart Factories, IIoT, Artificial Intelligence, Cloud Computing, Smart Factory Solutions, PLM, MES, ERP, Robotics, and Intelligent Logistics. With ctrlX Core at its heart, this ecosystem empowers users to achieve unparalleled efficiency, flexibility, and productivity.

The ctrlX AUTOMATION platform transcends traditional boundaries between device control, the IT world, and the Internet of Things. With its Linux-based operating system, real-time capabilities, consistent open standards, application programming technology, web-based engineering, and comprehensive IoT connectivity, ctrlX AUTOMATION reduces engineering and component costs by 30 to 50%. Furthermore, ctrlX AUTOMATION technology offers a range of programming languages, including PLC programming for device control, as well as advanced programming options in C/C++, Python, and Java for sophisticated applications. The solution also supports multiple connection protocols, facilitating seamless integration and efficient data exchange between various automation components.

Kassow Robot: Shaping the Future of Flexible Automation

Kassow Robots is part of the factory ecosystem that will be showcased at Automation World Vietnam 2024. With its unique and efficient 7-axis system, Kassow Robots can handle payloads ranging from 5 to 18 kg, operating radii from 850 to 1800 mm, and joint speeds of up to 225 degrees per second. These cobots offer not just superior speed and strength but also extended reach and higher payloads. Their user-friendliness provides companies with remarkable flexibility and enables small and medium-sized enterprises (SMEs) to achieve complex automation and programming efficiently and independently, without the need for robot experts.

Next-Generation Tightening Technology and Solutions

Bosch Rexroth is harnessing the immense potential of production processes in the field of connection technology and tightening with its new generation of products that excel in interactivity, connectivity, and collaboration. The portfolio includes cordless tightening tools, spindles, and control systems, impressing with maximum precision, reliability, and data security, as well as the evaluation of all data. Thus, the next generation of products meets the process requirements of the future while setting new standards in daily use, from operation and usability to ergonomics and modern design.

PRC7000 Spot Welding Controller: Cutting-Edge Spot Welding Technology

Bosch Rexroth will also introduce the PRC7000, the most comprehensive and advanced system for resistance spot welding, at the exhibition. The PRC7000 spot welding controller enables precise welding of different materials and offers functions that make processes easier and simpler for the future. This solution elevates welding systems to new heights, effectively meeting the demands and challenges of factories in Industry 4.0.

With over 225 years of experience, Bosch Rexroth is a trusted partner for advanced and innovative automation solutions. Through this exhibition, the company once again underscores its commitment to fostering the development of Vietnam’s manufacturing industry, helping manufacturers enhance productivity, shorten time-to-market, and achieve sustainable growth.

Experience Bosch Rexroth’s cutting-edge automation solutions first-hand at booth B.708 – B.710, Automation World Vietnam 2024, to receive expert consultations and discover the exceptional potential for your journey towards building the smart factories of the future.