One of the concerns in Vietnam today is the country’s lack of high-speed railways and the subsequent questions about the ability to construct, operate, maintain, and, most importantly, own the technology for such a project. The proposal aims to address this by outlining a plan to mobilize resources and encourage local businesses to participate in building the high-speed rail system.

The proposal suggests forming a consortium of local businesses to receive technology transfers.

Mr. Tran Thien Canh, Director of the Vietnam Railway Administration, stated that the experience of other countries shows that high-speed railways facilitate the formation of a railway industry and attract the participation of large conglomerates.

For example, South Korea received technology transfers from France and then engaged domestic industrial giants such as Daewoo and Hyundai to form a company, requiring the French supplier to sign a contract with this company for technology transfer.

In Vietnam, companies specializing in chips and electronics, such as VNPT and Viettel, or automobile manufacturers like Truong Hai, can participate. They can contribute not only in producing electronic components, accessories, or automobiles but also in railway-related industries.

According to the proposal, the planned high-speed rail line between the North and the South is expected to have a structure comprising 60% bridges, 10% tunnels, and 30% ground. In terms of construction, the Vietnam Railway Administration believes that, based on the experience of building the North-South Expressway, building bridges and tunnels requires advanced techniques, and local companies are fully capable of handling everything from design to construction.

Regarding the trains, Vietnam has already upgraded all old carriages into high-quality ones, and there are two railway industrial facilities: the Di An Locomotive Factory and the Gia Lam Locomotive Factory, established during the French period, now equipped with modern machinery, including CNC cutting machines. Some iron and steel companies have expressed their ability to produce rail steel if given the opportunity.

The rail and switch complex is more complicated than the ray, but if the market demand is large enough, domestic companies can participate in researching, producing, and supplying them.

The most complex aspect is the information, signaling, and train control systems, with only a few manufacturers globally, such as Hitachi (Japan), Alstom (France), and Siemens (Germany). Even China has only achieved over 80% self-sufficiency, still relying on core technology providers.

In a conversation with Tien Phong, a leader from the Ministry of Transport shared that one of the requirements for the high-speed rail project is for Vietnam to completely own the technology, including operation, maintenance, and replacement, and gradually produce some components. After consulting the experiences of 22 countries, especially the six with the most developed high-speed rail systems (Japan, France, Spain, China, Germany, and South Korea), several nations expressed their willingness to transfer technology to Vietnam.

To facilitate the participation of domestic businesses in the development of the railway industry, the proposal suggests that the Ministry of Transport create a special mechanism. This mechanism would allow the investors of high-speed rail projects, national railways, and urban railways to require general contractors and technology transfers. Additionally, investors can mandate local businesses to supply vehicles and equipment that can be produced domestically.

Along with this, there will be conditions for technology transfers and training in operation and maintenance for five years. Local businesses will be involved in assembling 30-40% of the carriages supplied, and railway-related products, materials, and equipment will be included in the priority list of key mechanical products in Vietnam’s mechanical industry development strategy to benefit from preferential policies.

The proposal also suggests forming a consortium of local businesses to receive technology transfers, research and development, and master operation and maintenance. They will gradually produce replacement components, equipment, information, and signaling systems and assemble and manufacture new carriages.

“If provided with suitable technology transfers, Vietnam has the potential to develop its railway industry, moving towards self-sufficiency and localization in manufacturing carriages, power supply systems, information, and signaling systems. We aim for complete autonomy in operation, maintenance, and producing replacement components for high-speed railways,” said a leader from the Ministry of Transport.

Allocating over $400 million for human resource training

Ensuring a skilled workforce to operate the high-speed rail system is another challenging aspect of the project. The Ministry of Transport’s proposal includes a training program for human resources in three forms (domestic, overseas, and combined training) and four levels of qualifications (technicians, engineers, masters, and doctors) for five subjects (state management agencies, project management units, operating units, training institutions, and research institutions).

The training will be funded by the project, with a total budget of approximately $348 million. Of this, the project operator will borrow about $340 million to train 13,880 personnel in management and operation and about $8 million to train 700 project management personnel.

Additionally, the proposal suggests allocating approximately $88 million from the project to train personnel for state management agencies, lecturers, and scholarships for students in specific fields such as metallurgy, mechanical engineering, electronics, telecommunications, automation, and artificial intelligence. It also includes building shared laboratories to serve training, research, and development.

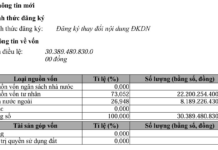

According to the Ministry of Transport, once completed, the Vietnam Railway Corporation (VNR) is expected to manage, operate, and exploit the entire infrastructure. They will be responsible for repaying the investment costs and will be provided with all necessary vehicles and equipment. As per the proposal, VNR will establish two companies: one for management and business and another to receive investment from the project for transportation business.

VNR’s leadership shared that they are preparing human resources to manage and operate the high-speed rail line. Once the proposal is approved for investment, the corporation will select some management staff and lecturers from the Railway College to undergo training first, followed by others. A training roadmap has been developed, and the duration of training will vary depending on the position and responsibilities.

“The most time-consuming training is for train drivers. VNR will select young train drivers with experience in operating conventional trains for initial training. The entire line will require over 700 drivers, but they will be trained in batches according to actual needs,” said VNR’s leader.