At a meeting of the Government’s Standing Committee with enterprises in September 2024, Mr. Tran Dinh Long, Chairman of the Board of Directors of Hoa Phat Group Joint Stock Company (stock code HPG), shared that the company has been preparing and researching the development of steel for high-speed rail tracks over the past 2-3 years.

Mr. Long affirmed that Hoa Phat is capable of supplying the required volume of 6 million tons of various types of steel for the project, particularly high-speed rail steel and high-strength prestressed steel. The company commits to delivering quality products, timely delivery, and competitive pricing, even lower than imported steel.

It is known that billionaire Tran Dinh Long personally visited factories of foreign businesses to study their product development strategies, with a focus on high-speed rail steel, in preparation for Vietnam’s ‘mega-project’ worth 67 billion USD.

“Hoa Phat has successfully produced steel with a difficulty level of 10, while high-speed rail steel is only rated as an 8”

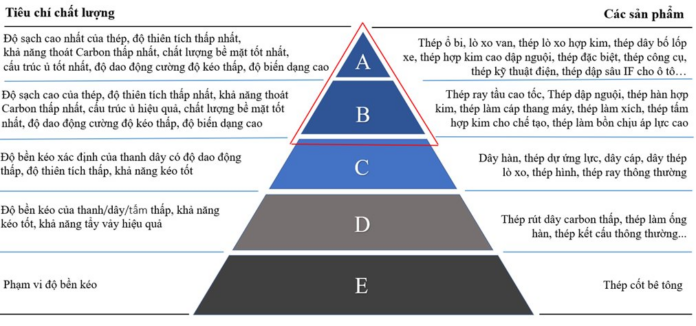

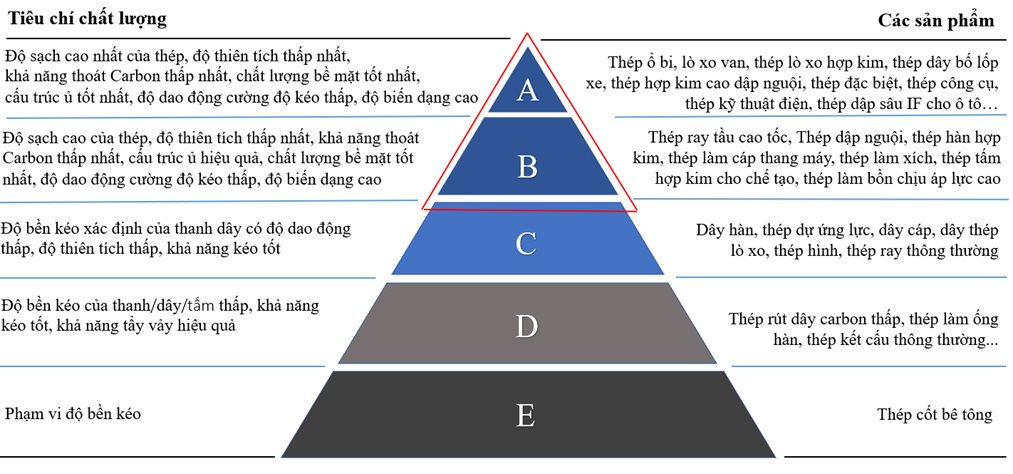

Steel experts categorize steel grades as follows:

As per the quality grades, steel used for bearings, spring valves, alloy springs, and tire cord steel for automobiles is ranked at the highest level. In simpler terms, if producing this type of steel is a challenge rated as 10, then producing steel for high-speed rail tracks is only a 8 in terms of difficulty.

Hoa Phat’s team of engineers has mastered the technology to create the most challenging and highest-quality products, such as cold-rolled wire steel, arc-welded steel wire, steel for elevator cables, weather-resistant steel plates since 2021, and especially steel coils for tire cord steel.

Tire cord steel demands an exceptionally high level of steel purity. The steel cords have a very small diameter of 0.15-1.80mm, resembling a hair strand, and the product requires unique mechanical properties, ultra-high purity, and minimal gas impurities.

Hoa Phat Dung Quat has been refining this special type of steel since 2022 at the Rolling Mill 3 of Dung Quat 1, supplying to Hyosung (South Korea) and Bekeart (Belgium). Additionally, Hoa Phat has obtained certification to supply steel materials for the production of elevator cables and crane cables for Tokyo Rope, Japan.

As the only Vietnamese steel manufacturer capable of producing high-tech steel, Hoa Phat ensures investment in equipment and technology transfer to produce the best and highest-quality rail steel, on par with European standards. Hoa Phat is considering transporting rails up to 120m in length to reduce welds on high-speed rail tracks, enabling stable operation at high speeds.

The G7 partners providing technology equipment to Hoa Phat, such as Danieli and SMS, are leading global suppliers of rail steel production technology in Europe and Asia.

Hoa Phat Sends Experts to Study Rail Technology

In October and November 2024, Mr. Tran Dinh Long, Chairman of the Board of Directors of Hoa Phat Group, along with a team of technology experts, directly visited several leading world factories in Europe that manufacture steel rails.

They studied the layout of the production technology equipment, operation and organization of production, technology production process, and quality control procedures throughout the entire process. This included the preparation of clean raw materials from iron ore, vacuum refining to achieve the highest level of metal purity and removal of harmful gas impurities, online quality control systems, UT equipment for detecting internal defects in steel rails (Ultrasonic testing), Hiprofile equipment for checking the geometric shape with lasers (laser profiling), rail straightening systems, and rail head hardening processes during the production of high-speed railway rails to ensure the highest quality standards.

The group began negotiations, collaborations, and technology transfers with leading global partners and equipment suppliers for the production of steel rails for high-speed railways. These partners have accompanied Hoa Phat for many years.

Hoa Phat Dung Quat also collaborated with the Faculty of Materials of Hanoi University of Technology to organize in-depth training courses on high-quality steel products, focusing on specialized steel types and complex production techniques, such as tire cord/tire belt steel for automobiles, electrical steel (silicon steel), and steel for high-speed railway tracks.

Hoa Phat is currently expediting the completion of necessary procedures for land clearance and the implementation of projects in the Hoa Tam Industrial Park, located in the Nam Phu Yen Economic Zone, Phu Yen Province. One of the projects includes the investment in the construction of the Hoa Phat Gang Thép Integrated Production Complex.

The expected product structure of this complex focuses on high-quality steel lines serving mechanical manufacturing, including rail steel, steel plates, structural steel, shaped steel, and smooth round steel bars (SBQ). With the availability of the site, Hoa Phat is ready to implement the project for the production of steel rails for high-speed railways, backed by its technology, skilled workforce, and production facilities.