Electric vehicles, and more specifically, those powered by clean energy, are being encouraged and adopted globally as a more environmentally-friendly alternative to traditional internal combustion engine vehicles that consume fossil fuels and contribute to pollution.

However, for electric vehicles to truly be a green solution, we need to consider not just the energy source but also the entire lifecycle of the vehicle and its components.

Among all the parts of an electric vehicle, the battery is arguably the most crucial as it stores and provides the energy needed for the vehicle to operate. With the increasing popularity of electric vehicles, battery recycling has become a pressing issue.

Li Cycle’s battery recycling plant.

What can be recycled and reused from batteries?

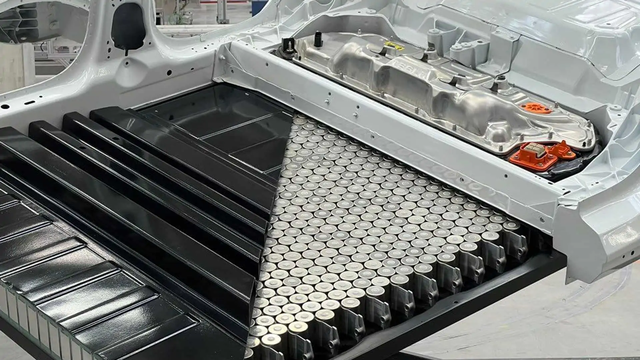

Electric vehicle batteries typically come in cylindrical or thin-film designs, depending on the manufacturer. These batteries are usually assembled into modules, and the cells may be glued to the battery pack (Cell-to-Pack technology) or directly to the vehicle frame (Cell-to-Chassis technology).

When it comes to recycling, the process involves dismantling and sorting the various parts of the battery pack for separate treatment.

Recyclable components within a battery pack include metal casings, wires, plastic casings, and even the individual battery cells themselves. These cells have a complex structure and contain valuable materials that need to be extracted and refined for reuse.

Infinite resources?

The individual battery cells are the most valuable and sought-after components. The metals within these cells, such as lithium, cobalt, manganese, nickel, and even aluminum, can be extracted through recycling.

To refine these metals, the batteries are crushed into a powder and then undergo multiple chemical treatment processes. The end product is typically pure metal, ready to be reused. This recycling and reuse loop can, in theory, be repeated indefinitely.

Recycling is generally a profitable venture in any industry, including automotive. Traditionally, vehicles are recycled for their steel or aluminum bodies. However, electric vehicle recycling presents unique challenges and opportunities, mainly due to their battery packs.

Battery recycling is essential to ensure electric vehicles remain a green choice throughout their lifecycle.

JB Straubel, former CTO of Tesla, founded Redwood Materials in 2017, a company specializing in electric vehicle battery recycling. Drawing on his experience and knowledge from his time at Tesla, Straubel has positioned Redwood Materials as a leading player in the industry, attracting millions of dollars in investment.

As Redwood Materials began selling recycled metals from batteries, it sparked a rush of investment in this recycling industry. Today, there are numerous startups and established companies in the US alone focusing on this sector.

Inside Redwood Materials’ facility.

However, one challenge faced by companies like Redwood Materials is the limited supply of batteries available for recycling. It has only been a little over a decade since Tesla launched its Model S, which sparked the electric vehicle revolution.

The number of batteries reaching their end-of-life is still relatively low, but with the exponential growth in electric vehicle sales, the battery recycling industry has immense potential for growth.

According to a Statista report, the market for electric vehicle battery recycling is expected to grow significantly in the coming years. In 2022, the market value was estimated at approximately $2.3 billion. From 2022 to 2028, experts predict an annual growth rate of around 27.3%, potentially reaching a value of $9.8 billion by 2028.

Battery Lifespan

Electric vehicle batteries are typically retired when their charging-discharging capacity drops below 70%. Depending on usage, this can occur after about ten years or even longer.

After their automotive life, these batteries can find a second use in energy storage systems for another decade or more. These systems store energy during low-demand periods and discharge it when demand exceeds energy production. Conversely, they can store excess energy produced when it surpasses consumption.

Tesla Model Y’s Cell-to-Chassis battery pack.

Currently, most energy storage systems are still in the conceptual stage rather than actual implementation. Companies that purchase and install these systems tend to favor new batteries over reused ones from electric vehicles.

However, if we envision a future where all vehicles are electric, the strain on the power grid will be significantly higher than it is today. In such a scenario, energy storage systems will play a crucial role in meeting the energy demands of the population.

A Sustainable Recycling Industry?

The key to the long-term viability of the battery recycling industry lies in the valuable metals that can be extracted from batteries. The demand for electric vehicles will continue to rise over time and surge as we approach the phase-out of internal combustion engine vehicles.

Establishing new mines, on the other hand, is a costly and time-consuming endeavor, especially with the stringent environmental regulations that must be adhered to. Unlike finite fossil fuels that are consumed through burning, the electricity from a battery is discharged, but the atoms of cobalt, for example, remain unchanged regardless of how many times the battery is used or reused. In this sense, discarded batteries can be viewed as a source of “future mining.”