Apple has come a long way in terms of durability, with their iPhones no longer being the fragile devices that required delicate handling. Starting with the iPhone 7, the first iPhone to feature IP-rated water and dust resistance, Apple has invested significantly in making their devices more durable, encouraging longer usage and contributing to environmental protection by reducing e-waste.

There have been numerous stories of iPhone’s durability, such as an iPhone X accidentally falling into a river and continuing to work fine even after two weeks of being submerged. More recently, an Englishman’s iPhone 13 Pro Max survived a 4,000-meter fall during a skydiving accident, with the phone remaining intact and looking as if it had merely fallen out of his pocket.

Achieving such durability involves optimizing hardware design and using more robust materials like Ceramic Shield for the display and Titanium for the frame. However, an equally crucial aspect is the rigorous testing process that Apple subjects their products to, ensuring they meet the durability standards set during the design phase. According to Apple, each product undergoes testing on 10,000 units before being released to the market!

During our visit to the WWDC 2025 event, we witnessed first-hand the brutal testing procedures. Interestingly, this testing facility is located off-site, away from the main Apple Park campus.

Harsh Environment Testing

In the environmental lab, Apple replicates various climatic conditions to ensure iPhones perform optimally in real-world scenarios. One of the tests involves exposing the devices to high humidity levels similar to those found in coastal regions to assess their resistance to corrosion.

In another chamber, fine dust is continuously blown for hours to simulate desert conditions, such as those found in Arizona. This artificial sandstorm is designed to push the devices to their limits, ensuring they can withstand harsh environments.

Additionally, there is a specialized machine that exposes the devices to direct sunlight and UV rays. Each sample is initially subjected to 100 hours of exposure, which is then increased to 200 hours, to determine when components start to degrade or fail.

Apple also tests the durability of its Studio Display screens in environments with temperatures up to 40°C and 90% humidity. While these conditions are not typical for indoor use, the test ensures that the displays remain resilient even in tropical or highly humid environments.

Water Resistance and Impact Testing

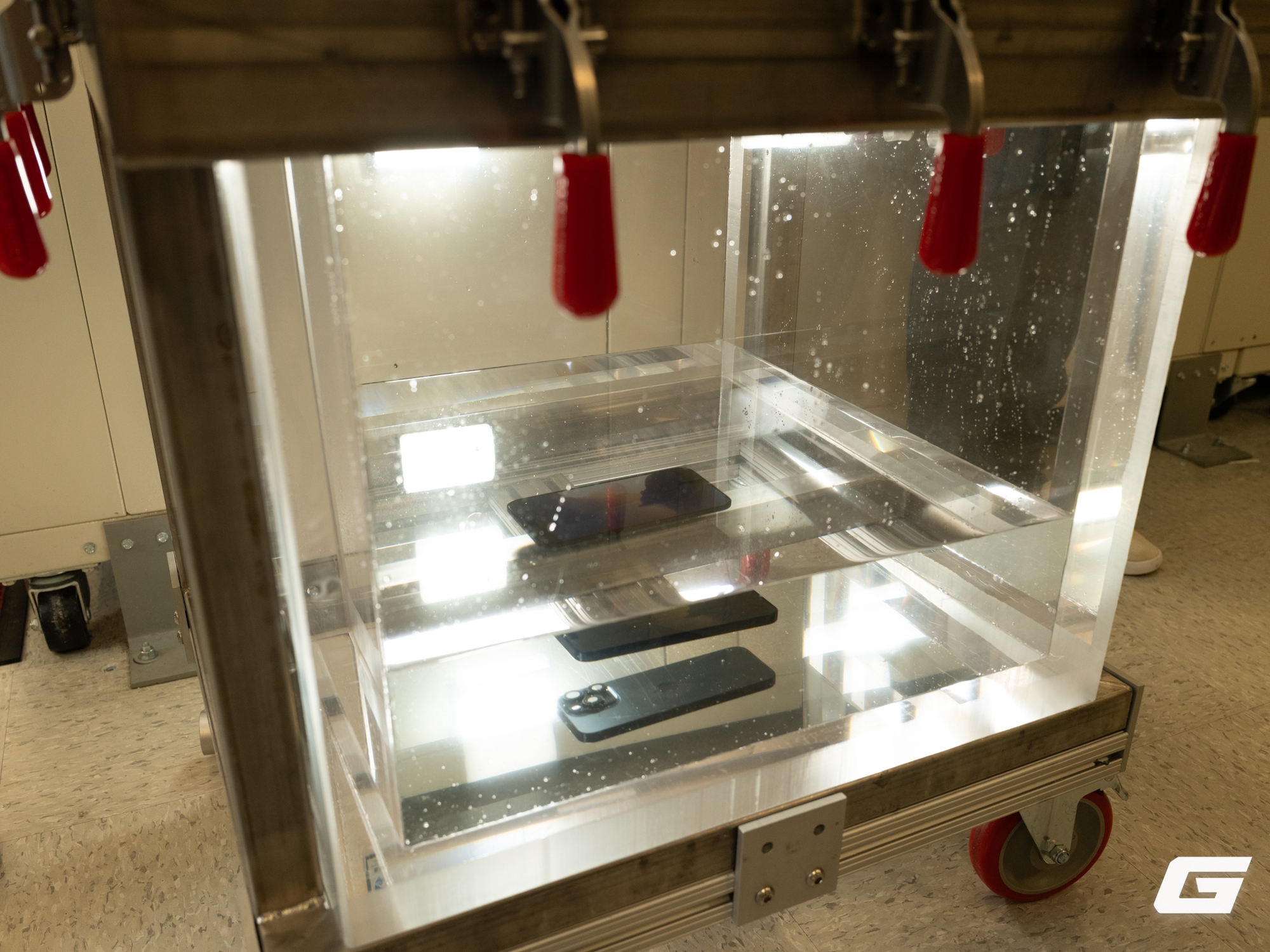

In the next section, standard water resistance tests are conducted, ranging from basic IPX1 to IPX6, IPX7, and even IPX8, which involves submerging the devices at significant depths for extended periods.

Nearby is the impact testing room, featuring two prominent systems: a massive steel drum that continuously spins, causing iPhones to collide relentlessly inside, and a robotic arm programmed to drop iPhones from various heights and angles onto surfaces like asphalt, granite, and plywood.

Apple even simulates the act of sitting down with an iPhone in the back pocket using a device that mimics the human buttocks.

Robot arms are used to drop iPhones from various heights and angles

Vibration and Mechanical Shock Testing

Another system focuses on long-term vibration testing, crucial for users who are frequently on the move, like motorcyclists or delivery riders. iPhones are mounted on a device that simulates continuous vibration, such as those experienced on a motorcycle or car seat, for extended periods to ensure that components do not loosen or fail due to mechanical shocks.

The ‘vibration table’ replicates continuous movement on a motorcycle or in a vehicle

To ensure the mainboard’s durability, Apple conducts physical shock tests similar to those performed on devices dropped from height. Slow-motion footage reveals that during impact, the board flexes, indicating its ability to absorb force and prevent cracking.

Battery Life Testing

Finally, in the battery testing room, each cell is charged and discharged repeatedly under various temperature conditions, with test cycles running up to seven times a day. Engineers also explained how they strategically place the battery within the device to make replacement as simple and quick as possible when needed.

While it may be painful to watch these expensive devices being put through such harsh tests, it’s reassuring to know that Apple is committed to ensuring their products are durable and long-lasting. So, the next time you hold an iPhone or MacBook, remember the sacrifices made by their counterparts to bring you a reliable and enduring device.