On June 23rd, in Nam Dinh province’s Nghia Hung district, Deputy Prime Minister Le Thanh Long attended the groundbreaking ceremony for the Xuân Thiện Group’s $98 billion Nam Dinh Green Steel Complex Project. As per the new development orientation, after July 1st, 2025, Nam Dinh will merge with Ha Nam and Ninh Binh provinces to form the new “Ninh Binh” province. The complex project by the Xuan Thien Group is expected to become an important driving force, contributing to regional and national economic growth.

This is Vietnam’s first green steel complex, featuring advanced and modern technology, which is among the best in the world.

The project has a capacity of 9.5 million tons of steel per year, using electricity and natural gas (LNG) and aiming to use green hydrogen for steel reduction, replacing the traditional coal-based steelmaking technology to reduce CO2 emissions and protect the environment.

The main products are high-quality steel that is not yet produced domestically, such as weather-resistant steel for mechanical engineering, shipbuilding, wind power pole production, automobile body and shell production, and weapons manufacturing…

Deputy Prime Minister Le Thanh Long and the delegates inaugurate the nearly 100,000-billion-VND Green Steel Project – Photo: VGP/Duc Tuan

As per the schedule, by June 2028, the first steel product will be released, and by June 2030, the complex project will be completed. To ensure the project’s highest efficiency, the Deputy Prime Minister requested that local authorities continue their supportive role, creating the most favorable conditions for project implementation, ensuring security and order, closely monitoring compliance with laws and environmental protection, and continuing to focus on stabilizing and improving the lives of people in the project area.

Investors, contractors, and consulting supervisors must concentrate their resources, intelligence, and technology, especially modern and advanced technology application, to shorten the construction time and soon put the project into operation.

The Green Steel Market: A Giant in the Making

Today, most of the world’s steel is produced through the basic oxygen steelmaking (BF-BOF) method, which heavily relies on coal for both iron ore reduction and energy source.

According to Future Business Insights, the global market for green technology and sustainable development in steel production is expected to reach over $89 billion by 2032, with a compound annual growth rate (CAGR) of 20.9% from 2024 to 2032. This significant growth is driven by increasing environmental regulations, consumers’ demands for sustainable products, and the steel industry’s awareness of the need to adapt to a low-carbon future.

The potential for green steel is enormous, considering that global crude steel production reached 1,888.2 million tons in 2023.

Decarbonizing the steel industry is a critical challenge that needs to be addressed if the world is to meet its climate goals. Steel production contributes about 11% of global carbon dioxide (CO2) emissions, making it one of the most polluting and emission-intensive sectors.

Illustration. Photo: ING Bank

Emerging Technologies: Paving the Way for Decarbonization

The quest for green steel has sparked a wave of technological innovation, with some promising approaches emerging as potential game-changers. These technologies aim to address the fundamental challenge of iron ore reduction without relying on carbon-intensive processes.

One of the most promising technologies is direct reduction based on hydrogen. This process uses hydrogen as a reducing agent instead of coal or natural gas, producing water as a byproduct instead of CO2. The HYBRIT project (Hydrogen Breakthrough Ironmaking Technology) in Sweden, a joint venture between SSAB, LKAB, and Vattenfall, has successfully produced the world’s first fossil-free steel using this method. The project aims to deliver fossil-free steel to the market by 2026.

Another innovative approach is molten oxide electrolysis, which uses electricity to separate iron from ore without carbon. Boston Metal, a startup spun out of MIT, is pioneering this technology and has attracted significant investment to scale up its operations, securing a $20 million Series C2 investment from Tokyo-based Marunouchi Innovation Partners, bringing the total investment to $282 million.

Carbon capture, utilization, and storage (CCUS) technologies are also being explored as a means to reduce emissions from traditional blast furnaces. While not a perfect solution, CCUS can play an important role during the transition period while more advanced technologies are developed and scaled up.

The Green Logistics Challenge: Can Vietnam’s Furniture Industry Stay Competitive?

The latest regulations from the European Union and the International Maritime Organization, coupled with a slew of climate commitments, are forcing exporters to measure and reduce carbon emissions for each container and voyage. The financial burden of going green presents a short-term challenge, demanding a comprehensive overhaul of Vietnam’s timber industry’s operational model.

The Oil and Gas Industry Under Pressure to Reduce Carbon Emissions

The oil and gas industry is at the forefront of sectors facing immense pressure to reduce carbon emissions. As a significant contributor to global greenhouse gas emissions, it also has a pivotal role to play in the transition to a low-carbon future.

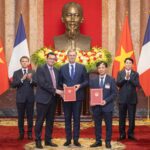

“Forging a Partnership with France in Aerospace and Space Technology”

On May 26, the Vietnam Academy of Science and Technology (VAST) signed a Declaration of Intent (DoI) with the French National Center for Space Studies (CNES) and Airbus Defence & Space (ADS) to collaborate on Earth observation satellite development. This significant event took place under the witness of Vietnamese President Luong Cuong and French President Emmanuel Macron.