Introducing the Long My Solid Waste Treatment Plant, a state-of-the-art facility with an investment of at least VND 1,500 billion. The plant is designed to process 500 tons of garbage per day and generate electricity with a capacity of 15 Megawatts, contributing to environmental protection and promoting a circular economy.

With modern technology, waste serves humanity once again. Illustration: Veolia (UK)

According to the latest updates on this billion-dollar project, the People’s Committee of Binh Dinh Province has approved the selection of investors for the project, which will utilize advanced waste-to-energy incineration technology. As a result, the consortium Greenity Binh Dinh Energy, headquartered in Thanh Xuan District, Hanoi, has been officially chosen as the investor.

As per the plan, the construction period will not exceed 24 months from the date of announcing the investor selection results, with a term of operation of 30 years from the date of land allocation. The plant is expected to occupy 100,400 square meters of land in Phuoc My Ward, Quy Nhon City, Binh Dinh Province.

The “Heart” of Vietnam’s Billion-Dollar Plant

The most crucial aspect of this project is the adoption of modern waste-to-energy (WtE) incineration technology. This technology is considered the “heart” of the plant and is a growing trend in many countries worldwide.

Globally, as of 2024, there are over 2,800 WtE plants, mainly in Europe and Asia, with a total capacity of approximately 576 million tons of waste per year. This equates to an average capacity of about 563 tons per day for each WtE plant.

The planned capacity of the Long My Solid Waste Treatment Plant matches the global average, indicating that the technology employed by the Vietnamese plant is highly advanced and on par with that of Europe and Asia.

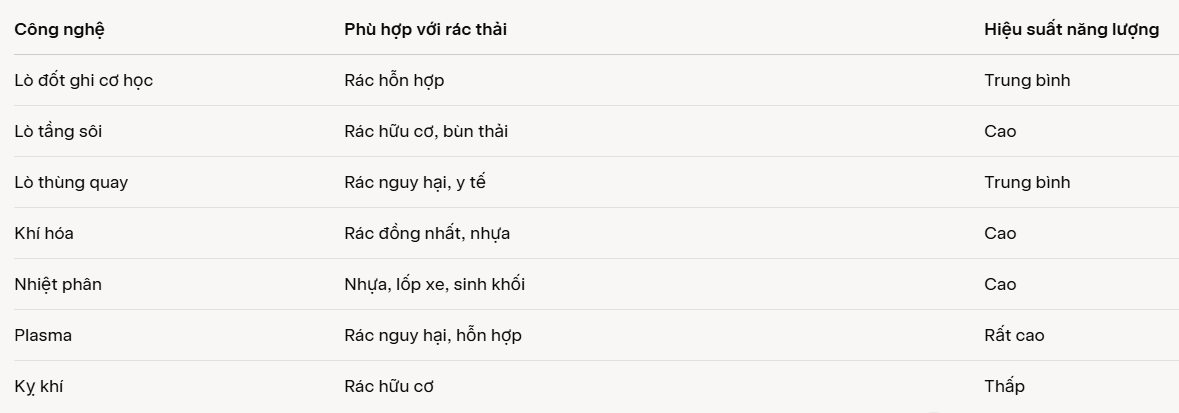

Some modern waste-to-energy technologies around the world.

With a capacity to process 500 tons of municipal solid waste daily and an expected electricity output of 15 Megawatts, the Long My Solid Waste Treatment Plant is set to serve the areas of Quy Nhon City, An Nhon Town, Tuy Phuoc District, and a part of Van Canh District.

In the future, the plant can expand its waste reception capacity according to the development needs and Binh Dinh Province’s solid waste management orientation by 2030. This aligns with global trends.

Illustration of waste recycling into energy. Source: Adobe

EcoProg forecasts that by 2033, there will be 3,100 plants in operation worldwide, processing over 700 million tons of waste annually.

According to the website, the market for thermal treatment and energy recovery from residual solid waste and other types of waste is continuously growing. Increasing waste quantities, shrinking landfill space in concentrated areas, and higher ecological standards drive the global development of WtE technology.

Sweden, a world leader in recycling, has turned WtE into a thriving industry. This initiative generates $100 million annually and reduces 2.2 million tons of CO2 emissions each year.

Creating a Clear and Transparent Legal Framework for EPR Implementation

The challenges faced in implementing Extended Producer Responsibility (EPR) effectively include an inadequate collection and recycling infrastructure, high recycling costs, difficulties in domestic consumption of recycled materials, and unclear legal frameworks without proper monitoring mechanisms.

The Circular Economy and Textile Industry: Necessary Changes to Mitigate Environmental Impacts in Vietnam

The Vietnamese textile industry is facing intense transformative pressure due to global sustainability demands and carbon emission reduction commitments. With a staggering $44 billion in export turnover in 2024, an 11.3% increase from the previous year, and its position as the world’s third-largest textile exporter, the industry contributes a significant 16% to the country’s GDP and employs approximately 12% of the industrial workforce.