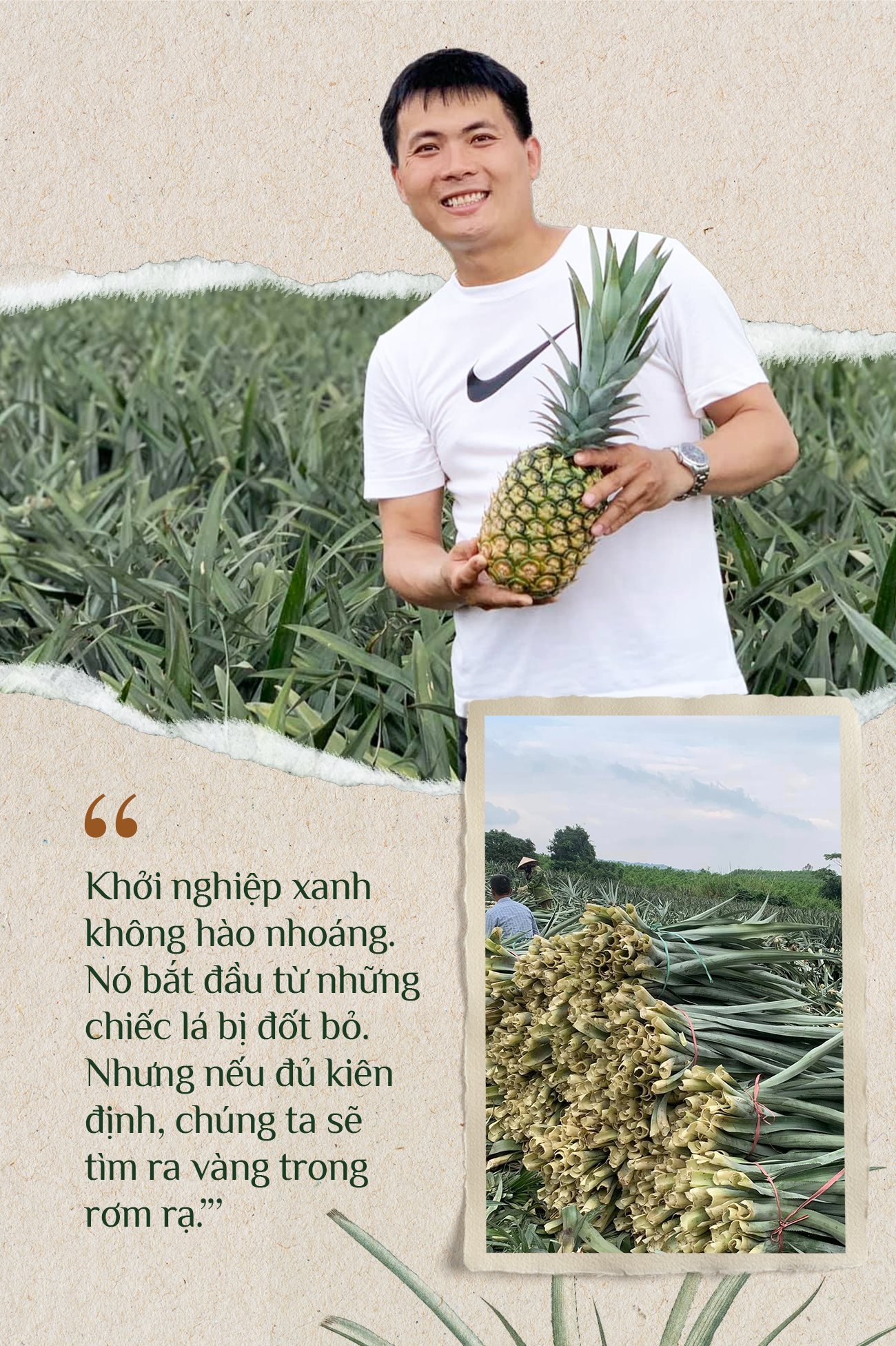

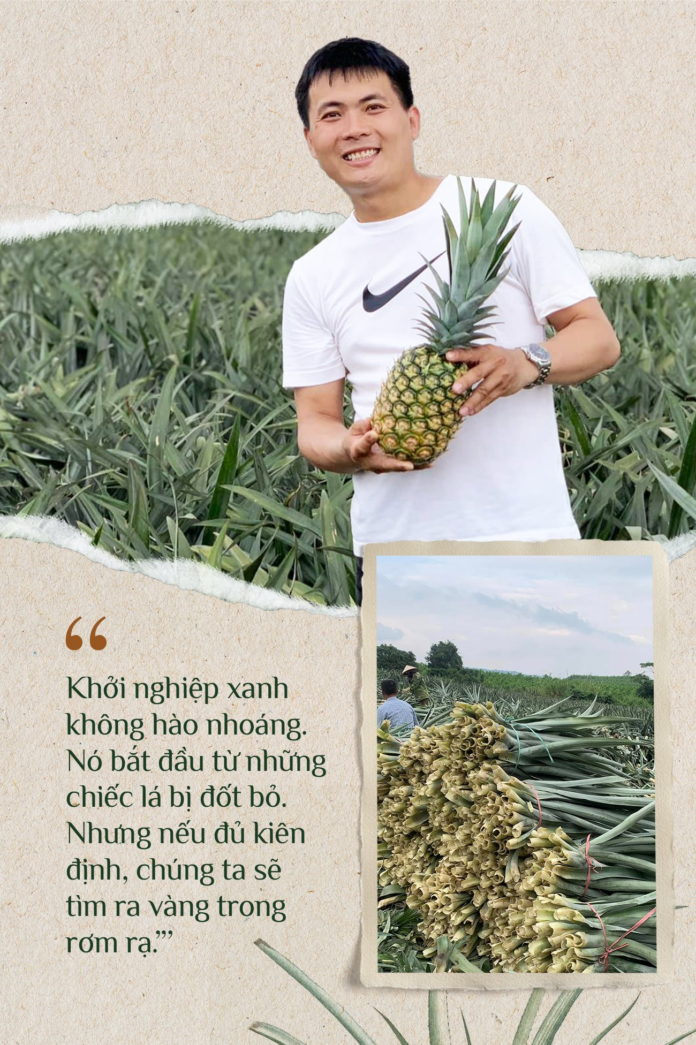

In 2021, amidst the scorching heat of Ninh Binh, Dau Van Nam, a mechanical engineer who had earned a high salary in Japan, stood amidst a vast pineapple field. He silently watched as the leaves were burned, the smoke stinging his eyes. Nam bent down, carefully picking up the leaves and manually stripping away the emerald green fibers, thinking to himself, “This is green gold,” even though no one else believed it but him.

When Nam left Japan, he brought back to Vietnam not only his savings but also the frustration of a young man who had lived in a “small alley, small street, small soul” environment. He wanted to start anew with something simple: a leaf.

LEAVING JAPAN, RETURNING HOME TO PLUCK LEAVES AND SEEK GREEN GOLD

Starting with a dream of getting rich from pineapple leaves, how far has his startup progressed in the journey of “plucking leaves to seek green gold”?

Dau Van Nam: (Laughs) Currently, Ecofa, the company I founded, sells about 30 tons of fiber per month. If blended with other types of fibers, this amount is sufficient to supply a yarn factory with 100 workers operating at full capacity for a month.

With a selling price of 260,000 VND/kg, these 30 tons of fiber bring in about 7 billion VND. However, this is the revenue before expenses—a very modest figure.

Vietnam has about 50,000 hectares of pineapple fields, producing over 2 million tons of leaves annually. With a fiber extraction rate of 2%, we can obtain nearly 40,000 tons of pineapple fiber. But on these vast fields, pineapple leaves are mostly burned. It’s not easy to make money from something considered waste! (laughs)

Specifically, what challenges did you face in your journey to profit from pineapple leaves?

Dau Van Nam: In the fashion industry, the lucrative parts are design, manufacturing, and branding. I was once very upset when a friend working for KEA (Sweden) told me that orders worth hundreds of millions of euros went to China and India. Vietnam sometimes only gets “a bone”—small orders for towels, with a total annual revenue of only 2 million euros, which is minuscule in comparison.

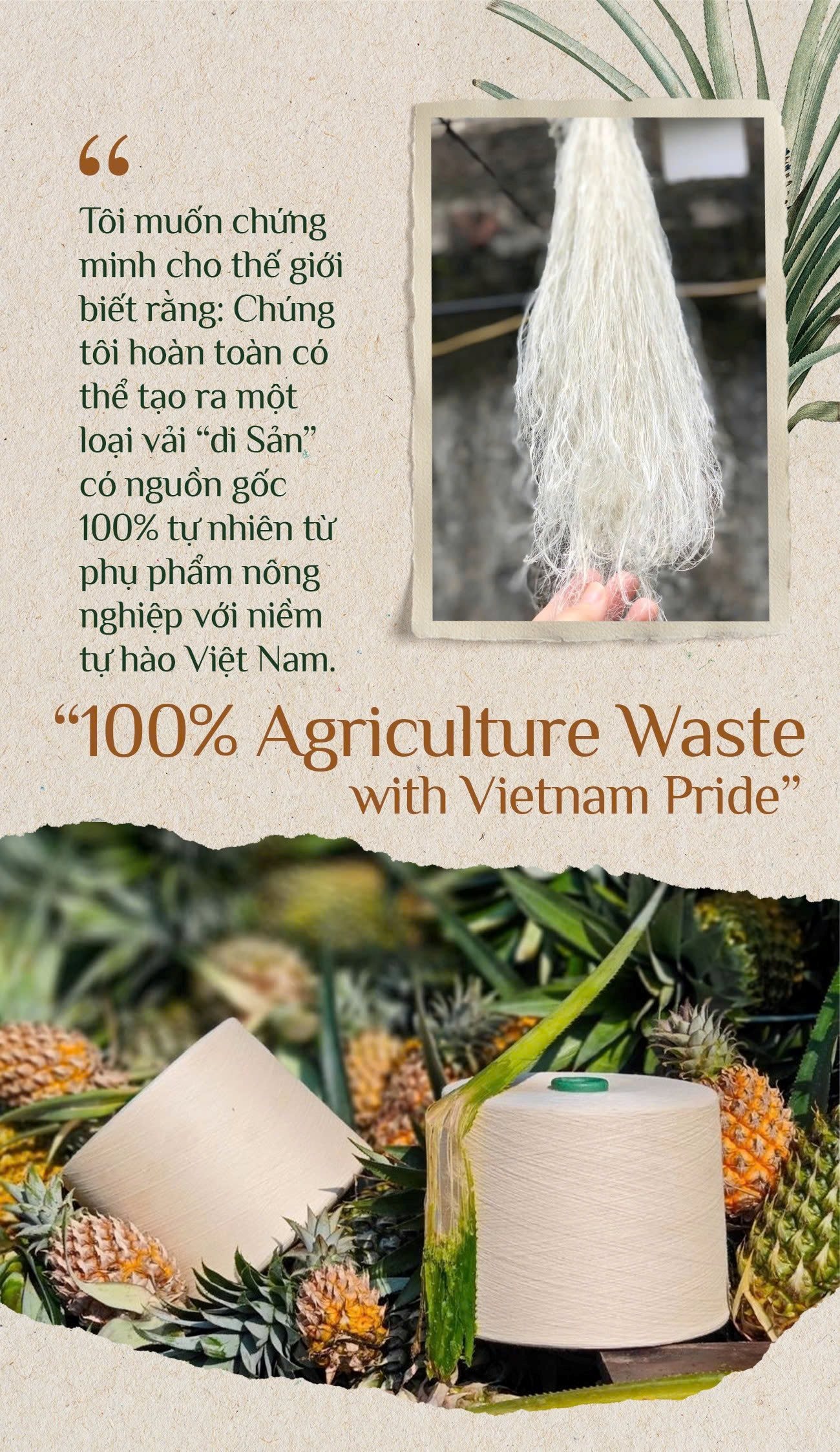

Additionally, most of the textiles’ raw materials have to be imported. I chose to go against the grain—creating green materials locally. I wanted to prove to the world that we can produce a type of “heritage” fabric made from 100% natural agricultural by-products with Vietnamese pride. “100% Agriculture Waste with Vietnam Pride.”

“IF CHINA CAN DO IT, WE WON’T BE ABLE TO COMPETE…”

So, in your opinion, does Vietnam have any advantages in producing this type of fabric compared to China if they also want to manufacture it?

Dau Van Nam: China doesn’t produce it because they don’t have a significant source of raw materials. Their predominantly temperate climate is not suitable. Pineapple leaves have a large biomass and must be processed into fibers while fresh, so they can’t be transported across borders. This is one of the reasons we chose pineapple fiber. Because if China could do it, we certainly wouldn’t be able to compete in terms of price or technology.

I know that consumers today have countless choices when it comes to natural fibers. Meanwhile, pineapple fabric is not as soft as cotton or bamboo, and it’s more expensive. How do you plan to compete?

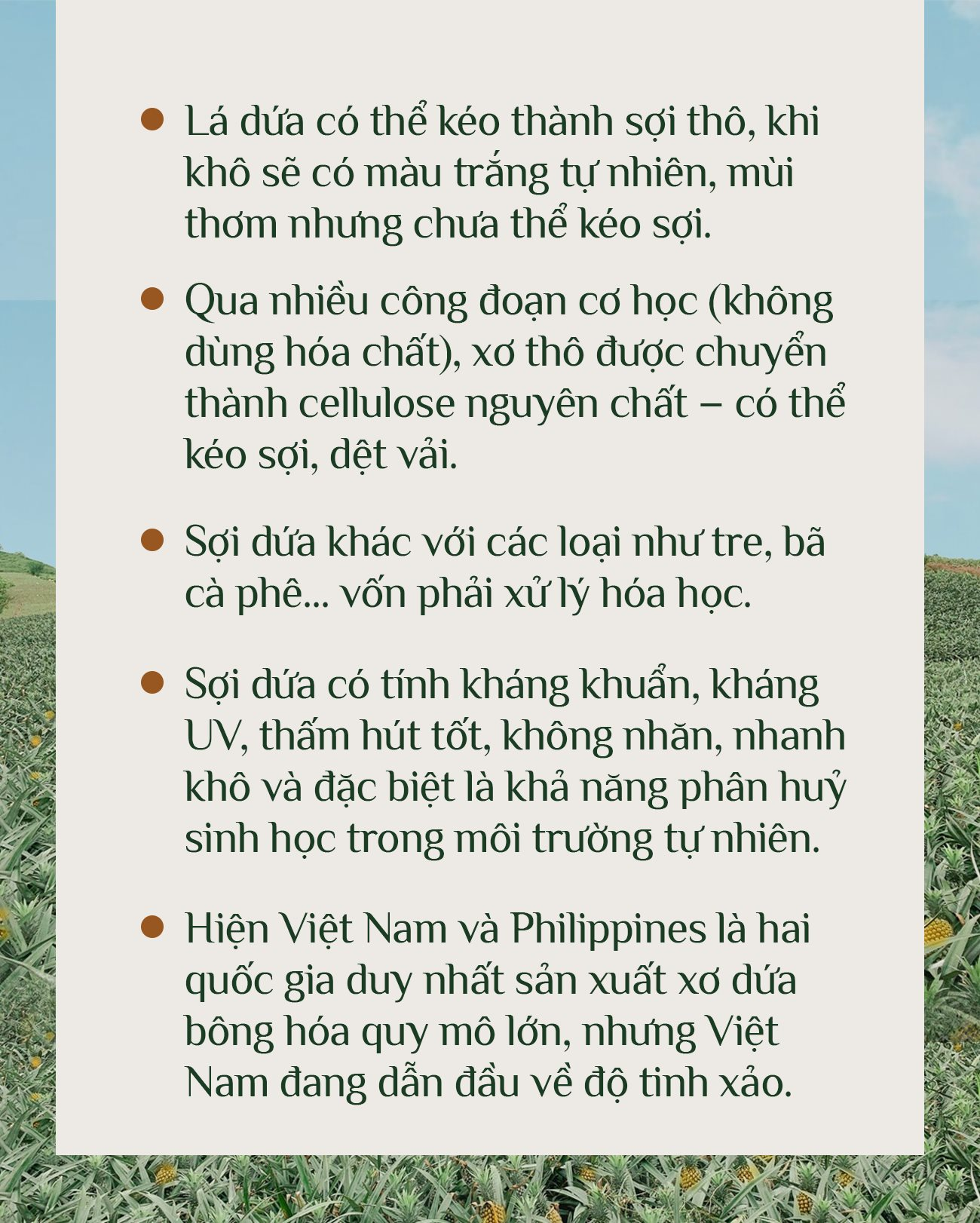

Dau Van Nam: It’s true that pineapple fiber is initially coarse and stiff, not comparable to cotton or bamboo in terms of softness. But we have three significant advantages:

– First, we don’t use any chemicals in the entire production process.

– Second, we preserve the natural properties of pineapple fiber.

– Most importantly, we have successfully transformed pineapple fiber to resemble cotton in terms of length, fineness, and softness, allowing us to blend pineapple fiber with all other types of fibers on the market. This is a technological breakthrough. Ecofa is one of the few companies in the world to achieve this on an industrial scale.

We position pineapple fiber in the premium segment, but at the same time, we strive to reduce costs—bringing pineapple fiber to the level of linen, which is a strong trend in the natural fiber industry.

“SEEING MY FIBER SAMPLE THROWN INTO THE TRASH… IT WAS A DIFFICULT FEELING TO DESCRIBE”

Besides what you mentioned, another critical factor in competition is core technology. How much has Ecofa mastered this technology?

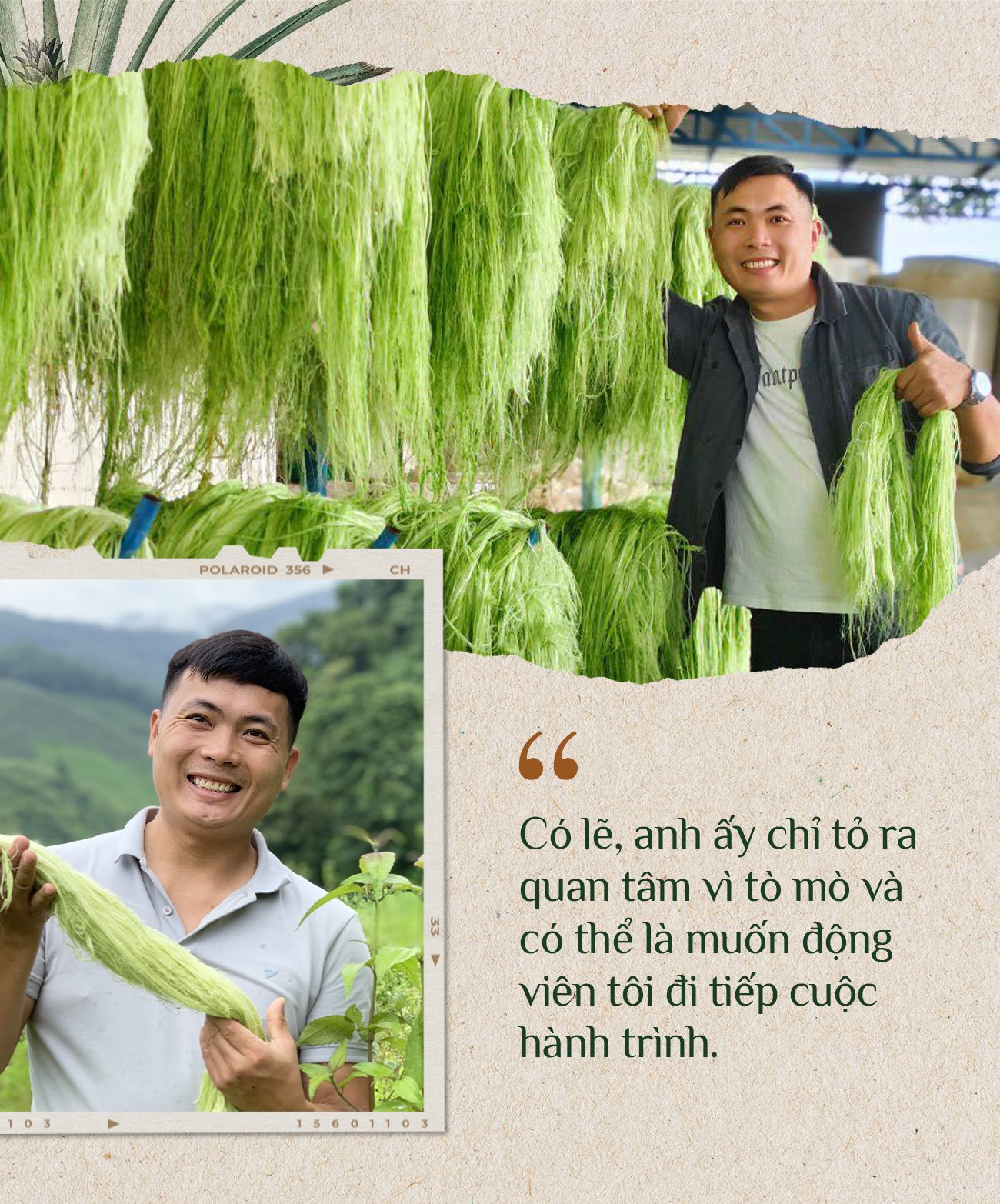

Dau Van Nam: For fiber production equipment, we design and manufacture them in Vietnam. For the fiber refining process, we improved upon machines purchased from Thailand and India to suit the unique characteristics of Vietnamese pineapple leaves. This means we have mastered the technology to the extent that we can produce our machinery.

How did the process of machinery manufacturing go?

Dau Van Nam: It took more than two years and numerous failures.

Initially, my teacher and I from the University of Technology created a semi-automatic machine. But the output was low, it was very noisy, and it wasn’t safe. After two years of tireless trial and error and spending over 2 billion VND, we finally perfected the automatic pineapple fiber extraction machine. The feeling at that time was unique—because I knew this was no longer a test, and we could develop it on a large scale.

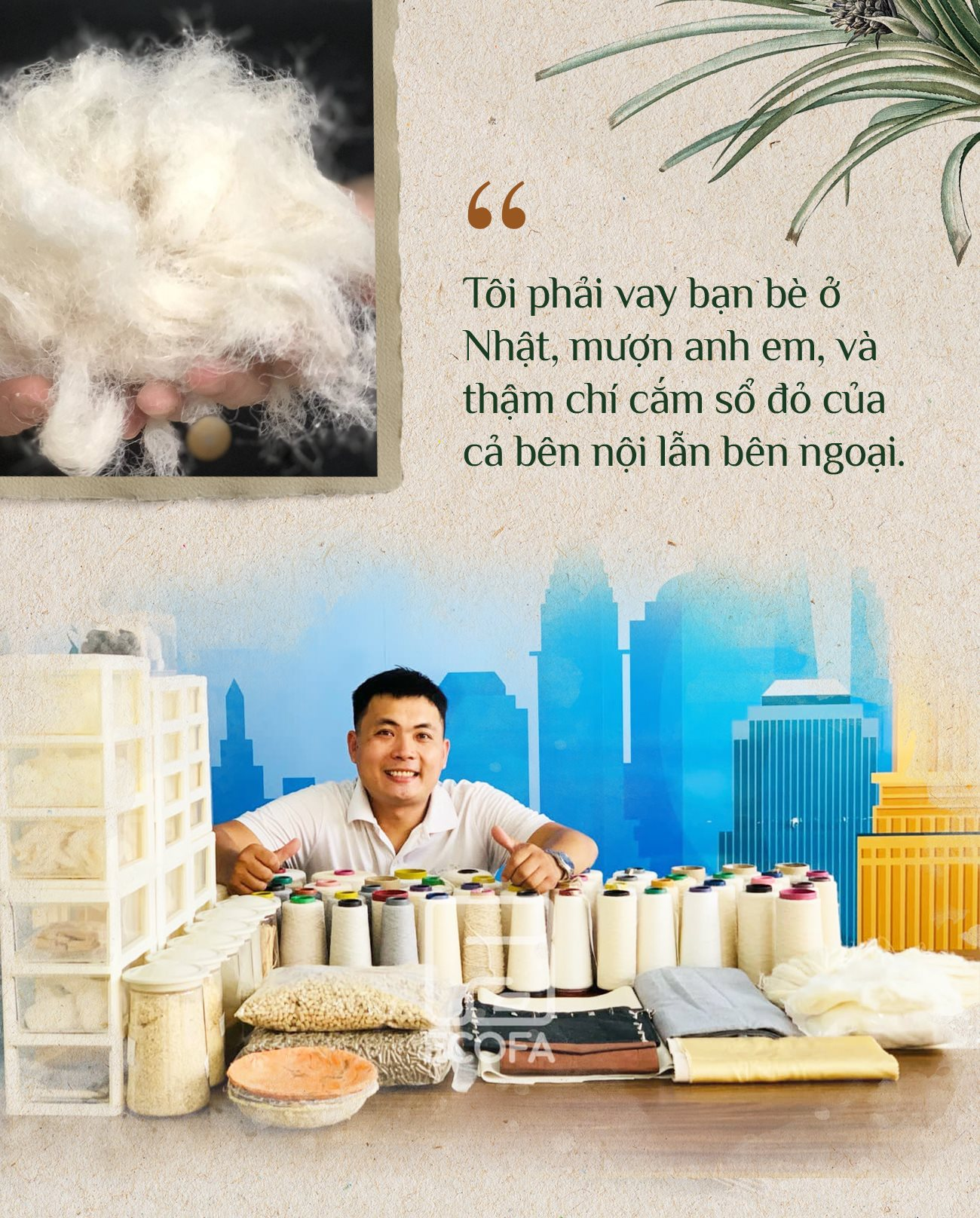

How did you manage the finances during this time?

Dau Van Nam: For the first two years, we hardly had any customers. All the capital came from my savings from my time in Japan.

By the end of 2022, I was almost out of money. I had to borrow from friends in Japan, ask for help from family, and even mortgage the family’s land and property . I did everything I could to continue because I knew this was a massive project that required a lot of money, time, effort, and perseverance.

When did you start producing refined fiber for yarn spinning, and how has the sales process been?

Dau Van Nam: Towards the end of 2022, we began researching refining technology, and by early 2023, we had our first refined product. From struggling to find customers, Ecofa now has six partners—including three domestic and three international companies—all of which are large enterprises. They usually take the time to research us online and then proactively reach out.

I realized that when you have a good enough product, sales take care of themselves.

It sounds like the sales journey has been quite smooth.

Dau Van Nam: (Laughs) Not at all. I still vividly remember the memory of “my fiber sample in the trash.”

Once, I took a bus from Nghe An to Phu Tho to introduce our product to a company. The meeting went well. The person in charge seemed very interested… But as I was leaving, I walked past his office window and saw my fiber sample in the trash.

It was a difficult feeling to describe. I didn’t understand why they would discuss cooperation when they didn’t seem to care.

Later, I realized that introducing a new material into the textile supply chain is extremely challenging. For state-owned companies or traditional yarn factories, switching to green materials is not easy. They need time, safety assurances, and they may not be enthusiastic about change. Perhaps he only pretended to be interested out of curiosity or to encourage me to continue my journey.

You’ve faced rejection, silence, and indifference—why didn’t you give up?

Dau Van Nam: I continued because of my promise to the farmers and because I couldn’t quit halfway, not after investing so much effort. There were times when I wanted to give up, but then I thought: Quitting now would be selfish and a disservice to the farmers who have been eagerly awaiting this project. Because they deserved a chance, and because the opportunity is still there, success is certain. This journey is not for those who give up easily.

Now that you’ve achieved initial success, things must be going smoothly, right?

Dau Van Nam: We utilize the leftover leaves after fiber extraction for animal feed, fuel, mushroom substrate, and even single-use paper. We’re also researching pineapple fiber for biological leather and mattress pads, but we haven’t commercialized those products yet.

We’ve achieved success, but there are still many challenges ahead!

PARTNERING WITH BAO LAN TEXTILE: “BRO, I’VE GOT THIS FIBER NOW”

But you’re not alone on this journey… ?

Dau Van Nam: I connected with Mr. Bao of Bao Lan Textile while still in Japan. After returning to Vietnam and experimenting with raw pineapple fiber, I contacted him again. He said that if I could produce a fiber similar to cotton, it would be very feasible.

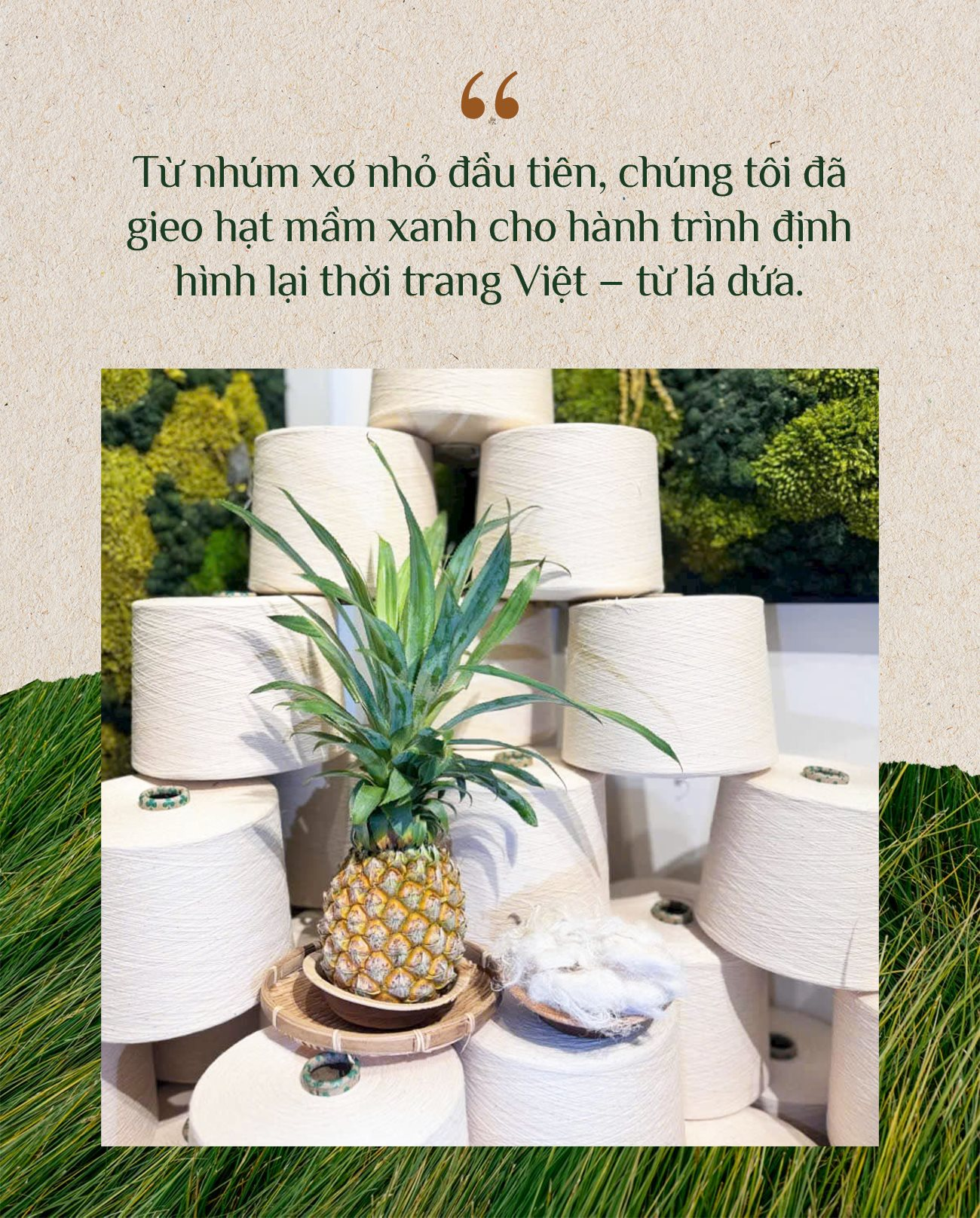

So we began the refining research phase, even without the necessary machinery. My colleagues and I manually cut, crushed, and shredded the pineapple fibers to create the first tufts of refined fiber. I still remember taking the fiber to the Institute of Textiles at 478 Minh Khai (Hanoi) for testing, where they required a minimum of 500 grams of refined fiber. We worked tirelessly to meet this requirement, and when traveling from Nghe An to Hanoi, I had to bring the raw pineapple leaves with me on the bus to shred and send the test results to our Japanese client.

When I told Mr. Bao, “Bro, I’ve got this fiber now!”

He immediately arranged a meeting. I flew from Vinh to Ho Chi Minh City. During our first meeting, we sat beside a tiny tuft of pineapple fiber. But Mr. Bao was very enthusiastic, saying, ” If you’ve managed to refine it to this extent, I will make this work! “

We shook hands quickly, but we’ve come a long way. Despite countless times when things seemed impossible, Mr. Bao never complained. We’ve created many faulty fabric samples: surfaces covered in lint, roughness, uneven dyeing, or even pinholes. These were expensive lessons, but Mr. Bao always encouraged us: From that first tuft of fiber, we have sown the seeds of change for Vietnamese fashion—starting with pineapple leaves.

Think of Friend-Shoring in the Textile Industry

“The Vietnamese textile industry is at a crossroads, facing a myriad of opportunities and systemic, geopolitical challenges. We can, and should, aim to become a strategic link in the global friendly textile supply chain,” said Dr. Hoang Xuan Hiep, Rector of the Hanoi University of Industry, Textile and Fashion.

![[Photo Essay]: Experts, Managers, and Businesses Unite to Forge a Path Towards Sustainable Green Industry](https://xe.today/wp-content/uploads/2025/07/z678592918-218x150.jpg)

![[Photo Essay]: Experts, Managers, and Businesses Unite to Forge a Path Towards Sustainable Green Industry](https://xe.today/wp-content/uploads/2025/07/z678592918-150x150.jpg)

![[Photo Essay]: Experts, Managers, and Businesses Unite to Forge a Path Towards Sustainable Green Industry](https://xe.today/wp-content/uploads/2025/07/z678592918-100x70.jpg)