The VinFast Hanoi Electric Vehicle Factory, located in the Vung Ang Economic Zone, is one of the most advanced electric vehicle manufacturing facilities in Vietnam and the region.

It took only 7 months from the commencement of construction to the completion and official operation of the factory.

According to VinFast, the factory covers an area of 360,000 square meters and includes large workshops such as body welding, painting, and assembly.

Additionally, a 240,000-square-meter auxiliary factory cluster is under construction and will continue to be expanded in the coming years.

Currently, the factory focuses on producing high-performance small urban electric vehicles, notably the VF 3, Minio Green, EC Van, and upcoming models in the development pipeline. The factory will have an initial capacity of 200,000 vehicles per year, equivalent to an average output of 35 vehicles per hour. It will be further expanded to increase capacity in the following years.

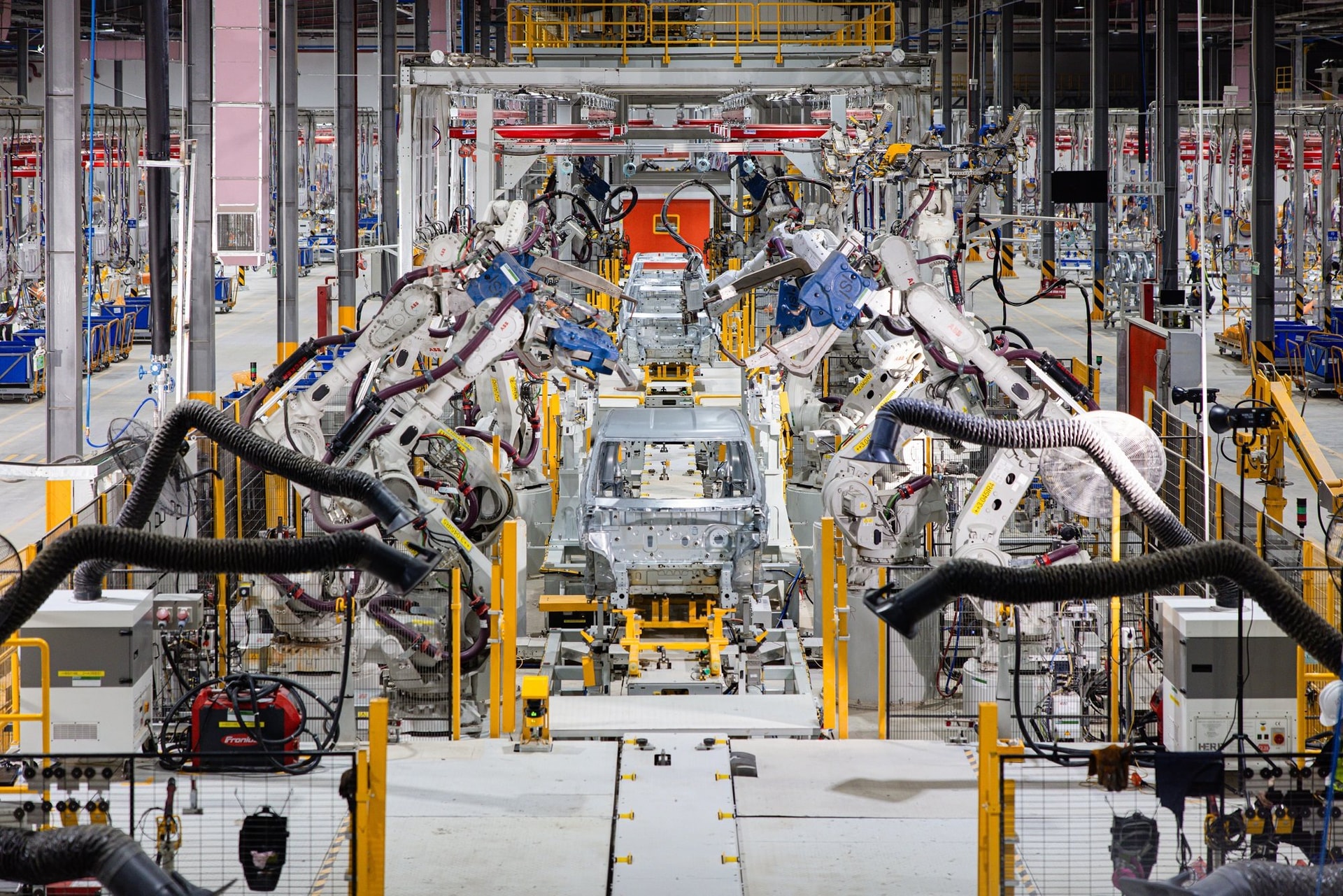

The body welding workshop is the heart of the production line, where metal parts are assembled and welded together to form a complete body shell. This “backbone” structure determines the safety, rigidity, and precise shape of each vehicle.

The workshop consists of specialized areas such as Tophat, Chassis, Minio Green, VF 3, and EC Van, and is continuously being expanded to meet production demands.

The workshop is equipped with highly automated welding robots from leading global brands such as ABB, KUKA, and FANUC.

The aluminum alloy chassis for the Minio Green model is welded in the Chassis area with a 95% automation rate, precisely positioned on clamping fixtures, and automatically welded by ABB robots using Fronius aluminum welding technology. This process ensures high stability, accuracy, and rigidity for the chassis. All welds are 100% macro-tested and have passed all safety tests according to international standards.

The engineers and technicians in the workshop are deeply trained and proficient in robot technology and advanced automation processes.

In the assembly workshop: The production line is supplied and installed by leading companies from India, integrating smart conveyor systems and automated guided vehicles (AGVs) with a high level of automation.

A notable feature is the ability to assemble multiple vehicle models on the same line, offering superior flexibility. To complete a vehicle, the nearly 1.5-kilometer-long assembly line has a capacity of up to 35 vehicles per hour, ensuring high efficiency and consistent quality.

Each vehicle is assembled from over 2,500 major components, with the entire operation process strictly controlled.

The painted bodies are automatically transferred from the Painting Workshop to the Assembly Workshop via an overhead conveyor system.

The 15 main assembly lines handle critical processes such as interior and exterior installation, engine and chassis assembly, final assembly, and quality control.

On the final assembly line, vehicles are programmed with control software and automatically filled with necessary fluids such as coolant, brake fluid, power steering fluid, and air conditioning gas, while data is automatically stored in the system.

Subsequently, the vehicles undergo rigorous tests at the end of the line, including vibration, noise, lateral slip, tire balance, water tightness, emissions, lighting, horn, and other safety criteria…

Finally, each vehicle undergoes a road test on a 1-kilometer track featuring 10 real-world terrain simulations to comprehensively assess its performance.

In the first five months of 2025, VinFast emerged as the leading automotive brand in Vietnam, with over 56,000 vehicles sold. The VF 3, VF 5, and VF 6 models are the top-selling vehicles in the market. VinFast electric vehicles are also gaining popularity among consumers in international markets such as the Philippines and Indonesia.

Currently, VinFast has five factories under development in Vietnam, the United States, India, and Indonesia. Among these, the VinFast factories in Hai Phong and Ha Tinh, Vietnam, are already operational, and the factories in India and Indonesia are expected to be inaugurated soon to cater to strategic international markets.

Vinfast to commence construction of electric vehicle manufacturing plant in India just over 1 month after signing MoU

VinFast Auto announced the Groundbreaking Ceremony of its Integrated Electric Vehicle Production Facility in Thoothukudi City, Tamil Nadu, India, on February 25, 2024. This event signifies a significant milestone in the strategic partnership between VinFast and the Government of Tamil Nadu, aiming to promote green transportation development in India and the region. On February 21, 2024.

![[Photo Essay]: Experts, Managers, and Businesses Unite to Forge a Path Towards Sustainable Green Industry](https://xe.today/wp-content/uploads/2025/07/z678592918-218x150.jpg)

![[Photo Essay]: Experts, Managers, and Businesses Unite to Forge a Path Towards Sustainable Green Industry](https://xe.today/wp-content/uploads/2025/07/z678592918-150x150.jpg)

![[Photo Essay]: Experts, Managers, and Businesses Unite to Forge a Path Towards Sustainable Green Industry](https://xe.today/wp-content/uploads/2025/07/z678592918-100x70.jpg)