“Mineral Commodity Summaries” (MCS) published by the US Geological Survey (USGS) in March 2025 revealed that Vietnam ranks 6th among the top 8 countries with the largest rare earth reserves in the world.

With 3.5 million tons of rare earth reserves, Vietnam ranks above the US (1.9 million tons) and Greenland (1.5 million tons).

Vietnam’s rare earth mines are mainly located in the Northwest region, especially in the provinces of Lai Chau and Lao Cai. Some mines are also found in the coastal provinces of North Central and Central Vietnam.

Interestingly, despite having the sixth-largest rare earth reserves in the world, Vietnam’s extraction efforts are limited due to technological constraints and environmental concerns.

Understanding this, Posco International Group – one of the largest steel producers in South Korea and the world – has expressed its willingness to cooperate with Vietnam in investing and transferring rare earth extraction and refining technology.

This proposal was made during the state-level visit to South Korea by General Secretary To Lam and his spouse. Accordingly, on the morning of August 12, 2025, Minister of Industry and Trade Nguyen Hong Dien worked with the Chairman and CEO of Posco International Group – Mr. Lee Kye-In.

Why is Posco International’s proposal attractive?

At the meeting with Vietnam, the head of Posco International affirmed that Posco is capable of in-depth cooperation with Vietnamese enterprises in the extraction, classification, and refining of rare earths. The purpose is to create products as raw materials for the production of permanent magnets.

Image of rare earth metals. Source: Anastasiia | Stock.adobe.com

According to Stanford Magnets (USA), permanent magnets play a crucial role in the world’s clean energy transition. They are indispensable in modern industry and technology, especially in “green” fields such as electric vehicles, renewable energy, and green energy…

This aligns with Vietnam’s economic development orientation in 2025 to achieve 8.3 – 8.5% growth, creating momentum for double-digit growth in the following years. According to Minister Nguyen Hong Dien, with this target, Vietnam’s energy demand is expected to triple the current capacity. Therefore, Vietnam is promoting the development of renewable energy and new, clean energy sources such as natural gas, liquefied natural gas (LNG), and nuclear power…

There are 17 rare earth metals, divided into two main types: Heavy and Light. Heavy rare earths, with higher atomic weights, tend to be rarer and more difficult to process, making them more valuable than light rare earths with lower atomic weights.

Back to the story of rare earths.

Rare earth metals (REMs) are essential in the production of high-performance permanent magnets.

High-performance permanent magnets (such as NdFeB – the strongest type of permanent magnet currently) rely heavily on rare earth elements such as neodymium, dysprosium, and praseodymium.

This is why Posco International focuses on rare earth separation and refining technology to produce permanent magnets, helping Vietnam take advantage of its “sixth-largest reserve in the world” status, while also helping Posco increase its rare earth supply – a material that South Korea still imports in large quantities.

What rare earth refining technology does Posco International possess?

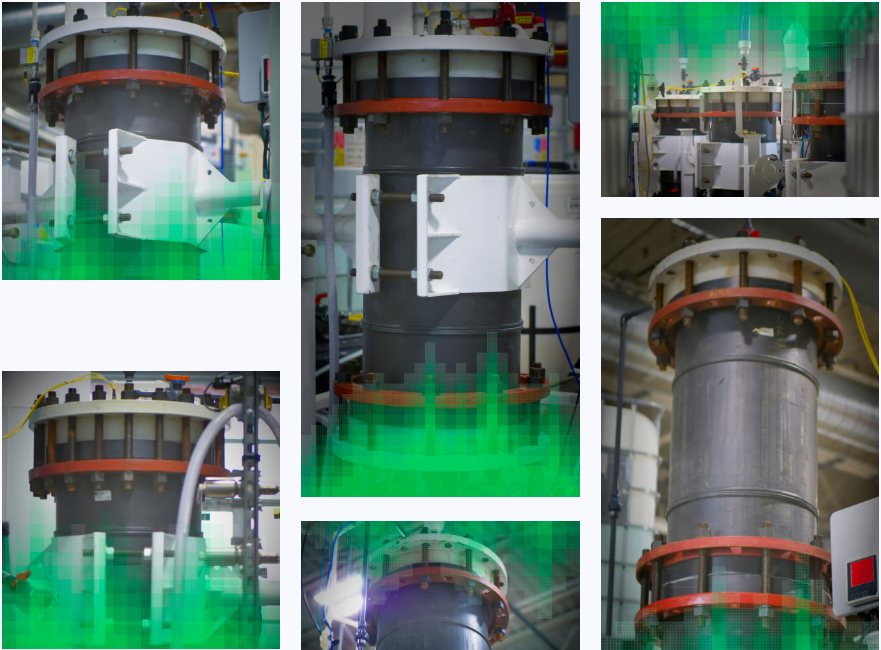

One of Posco’s trump cards comes from its cross-continental collaboration with ReElement Technologies Corp., an American company specializing in rare earth and battery material refining, owned by American Resources Corp.

Starting in 2024, ReElement will integrate its rare earth magnet recycling and refining process into Posco’s global rare earth permanent magnet production network, according to Recyclingtoday.

ReElement utilizes patented technology to separate and refine rare earths and critical battery materials.

ReElement’s Purification & Separation Columns system for rare earth separation and refining. Image: ReElement

Unlike conventional hydrometallurgical processes, ReElement’s rare earth separation and refining technology (Purification & Separation Columns) maximizes surface contact area by utilizing columns and resins.

The advantages of this technology are “4 reductions”: reduced investment and surface area, as well as reduced environmental impact and chemical usage for rare earth separation and refining.

The American Resources Group stated that ReElement would become the main refiner in North America, supplying Posco with heavy and light rare earth elements and supporting Posco’s permanent magnet business as they fulfill their recently announced original equipment manufacturer (OEM) contracts worth nearly $900 million.

“Vietnam’s Strategic Advantage: Prime Minister Vows to Develop Semiconductor Industry”

“Prime Minister Pham Minh Chinh emphasized the development of the semiconductor industry as a strategic breakthrough and a key focus area. He underscored that it is not only a possibility but also a determination, leveraging Vietnam’s unique potential, prominent opportunities, competitive advantages, and strategic direction.”