Electric vehicle accidents and fires often occur simultaneously, causing consumer hesitation due to safety concerns. However, a crucial fact is that to date, no collision-related fires have occurred in Mercedes-Benz’s electric vehicle accident investigations.

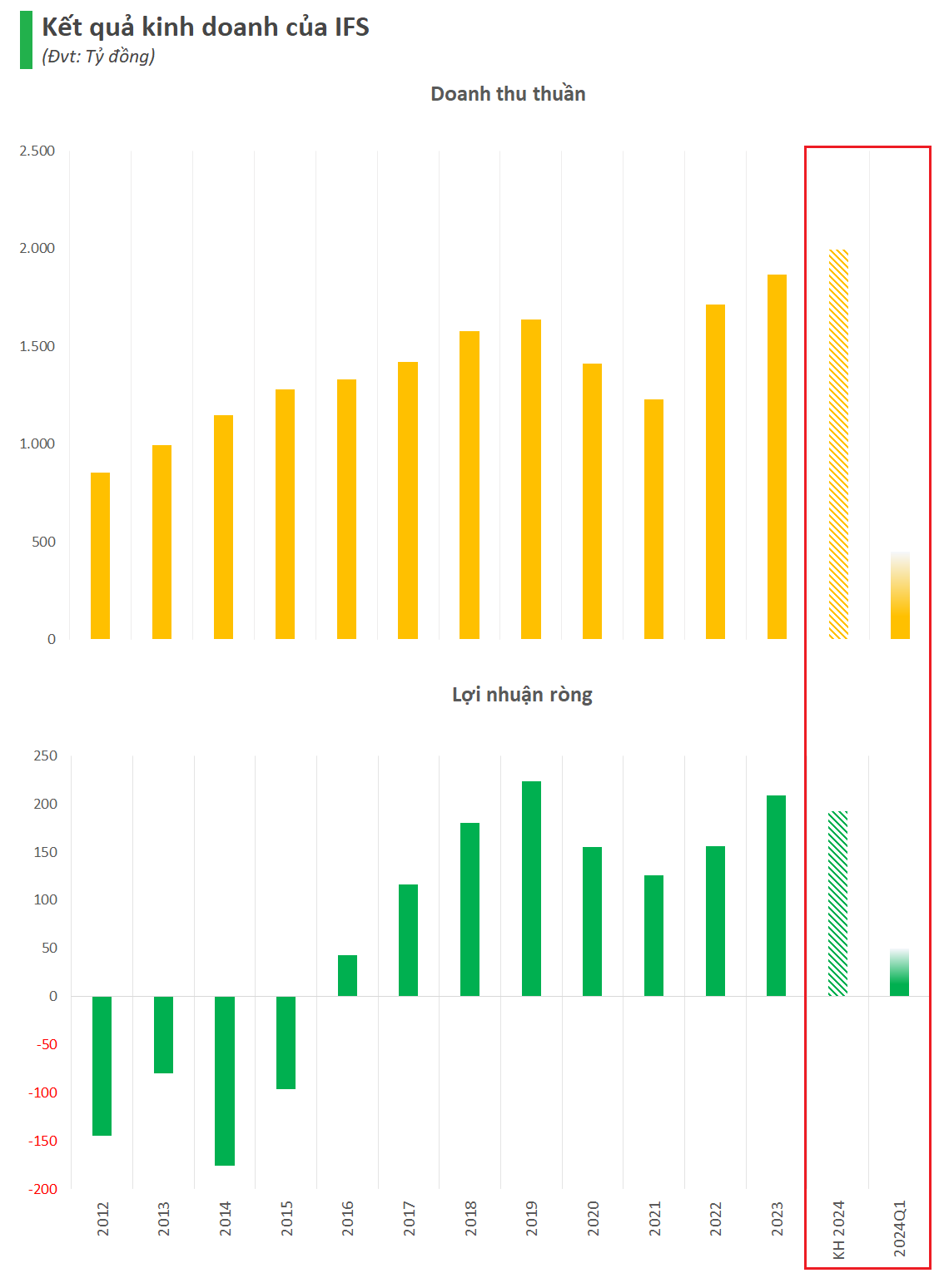

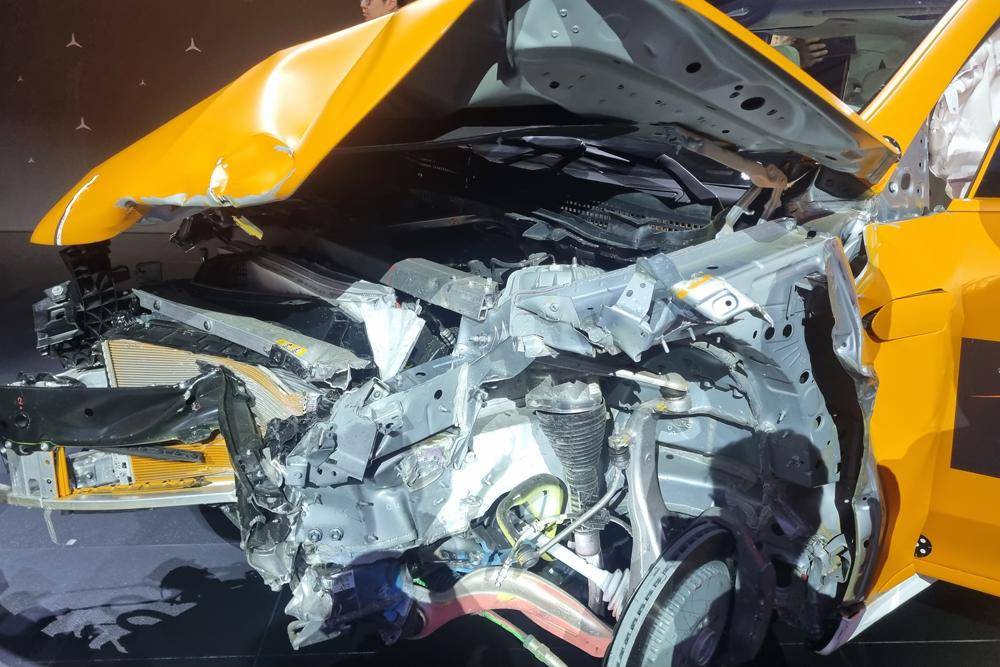

At the recent “Electric Vehicle Safety Report” event in South Korea, Mercedes-Benz showcased the compact electric SUV Mercedes-Benz “EQA” and the large electric SUV “EQS SUV” post-collision to substantiate this claim.

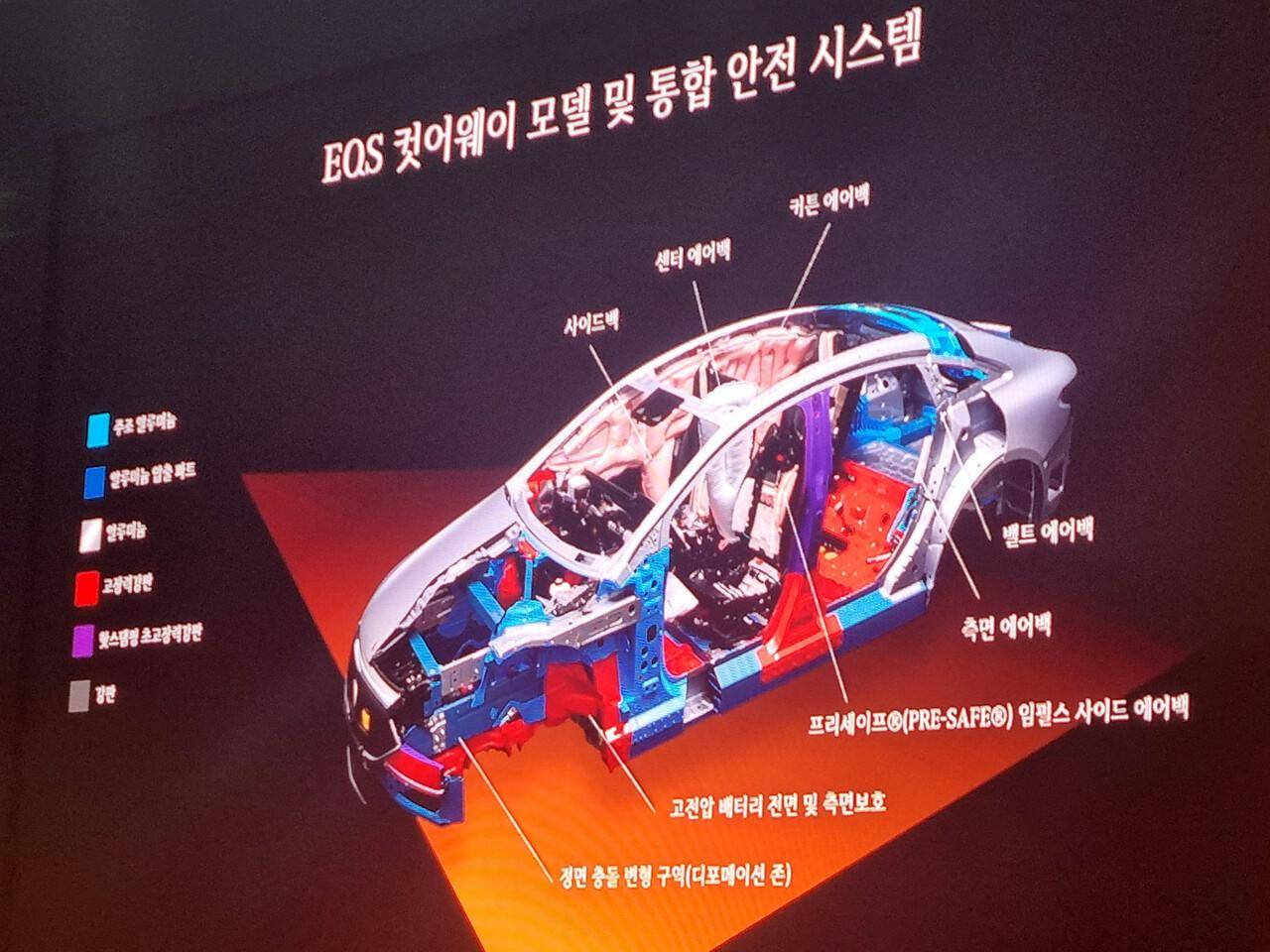

Mercedes-Benz electric vehicles are designed to absorb impact and protect the battery from damage. The battery is strategically placed in a safe area within the vehicle, typically under the floor or between the axles. The battery casing is made from a robust composite material, offering high fire and impact resistance.

The displayed vehicles were previously involved in the world’s first head-on electric vehicle crash test conducted by Mercedes-Benz in October last year. Departing from conventional crash tests (where vehicles are usually crashed into a wall), Mercedes-Benz orchestrated a collision between a 2.2-ton EQA and a 3-ton electric SUV EQS.

Mercedes-Benz employs a multi-level battery system to safeguard against damage and fire. This system incorporates sensors to monitor battery status, relays to disconnect power in emergencies, and a cooling system to maintain optimal battery temperature.

During the test, the vehicles were directed to approach each other head-on, colliding at a speed of 56 km/h. Although it was a frontal collision, the overlap area between the two vehicles was approximately 50%. This resulted in a relative speed of 112 km/h, constituting a more severe test environment than the current European New Car Assessment Programme (NCAP) crash test regulations (typically conducted at 50 km/h).

Mercedes-Benz electric vehicles are equipped with numerous safety features that reduce accident risks and protect drivers and passengers in the event of a collision. These features include ABS brakes, Electronic Stability Control (ESC), Brake Assist System (BAS), and Blind Spot Warning.

Observing the aftermath, the front sections of both vehicles sustained significant damage, yet the A-pillars and roof frames remained intact. All four doors operated normally, and the separation between the driver and passenger compartments and the front and rear spaces was securely maintained.

Julia Hinners, a collision safety engineer at Mercedes-Benz Group AG, elucidated: “The engineer’s task is to design a deformable space that can absorb impact to the greatest extent and arrange the parts delicately. By dispersing the force, the survival space for the driver is ensured.”

Mercedes-Benz electric vehicles are outfitted with multiple safety features to safeguard drivers and passengers in the event of an accident. The crash tests serve as a testament to the effectiveness of these safety features.

Mercedes-Benz electric vehicles are equipped with high-voltage batteries that automatically disconnect post-accident. The honeycomb structure surrounding the battery aids in impact absorption. The Mercedes-Benz accident investigation team has analyzed various accident scenarios and strategically placed high-voltage components in areas with the lowest likelihood of vehicle deformation. The robust casing used for high-voltage parts also contributes to minimizing damage.

Additionally, these vehicles feature a manual disable function, allowing emergency responders to manually sever the electrical cable before rescue operations. This enhances the safety and speed of passenger extrication from the vehicle.

Mercedes-Benz has also developed and introduced eight types of battery protection systems. Despite conducting several electric vehicle crash tests, they have never encountered a fire incident.

Mercedes-Benz plans to continue its accident investigations, driving tests, and safety system updates in alignment with its “Vision Zero” goal of achieving accident-free driving by 2050. The Mercedes-Benz Group Accident Research department, established in 1969, boasts over 60 years of crash test experience. This department is pivotal to realizing the “Vision Zero” objective.

Mercedes-Benz has conducted several crash tests to demonstrate the safety of its electric vehicles. In a recent test, two Mercedes-Benz electric SUVs were crashed head-on at a speed of 56 km/h. The results showed that the passenger compartments of both vehicles remained intact, and there was no risk of fire or explosion.

Mercedes-Benz emphasizes, “Safety is at the core and in the DNA of the Mercedes-Benz brand. For the first time in the automotive industry, the company established its own accident research department, and 20,000 engineers are working tirelessly to make accident-free driving a reality.”

References: Qctt, Caranddriver