In 1997, Meggitt Group (Paris) invested in Dong Nai by establishing Meggitt Vietnam Co., Ltd (Artus Vietnam Co., Ltd) – the first and only company in Vietnam at that time specializing in manufacturing transformers, control equipment for the aerospace industry and repairing aircraft equipment. The initial registered capital was 17 million USD.

In an interview from 2005, Mr. Tran Quang Hung (Paul Tran) – Managing Director, stated that Artus Vietnam imports raw materials from abroad for production and exports to the parent company or partners, manufacturing according to the orders of partners (in France and the United States). The products are inspected in Vietnam and in France with a strict process following international standards.

The largest customer is Airbus and Artus Vietnam started producing transformers for the A380 aircraft in September 2004, according to partner orders.

To meet large orders, Meggitt Vietnam doubled its production capacity by inaugurating the Aircraft Equipment Manufacturing Plant in 2018.

Inauguration of the Aircraft Equipment Manufacturing Plant at Meggitt Vietnam Co., Ltd in Bien Hoa 2 Industrial Zone in 2018

Years after the emergence of Artus Vietnam, Vietnam began to attract more and more “eagles” to enter the aircraft component industry, becoming a production hub of the world.

With the production of aircraft engines, Hanwha Group (South Korea) established Hanwha Aero Engines Co., Ltd located in Hoa Lac Hi-Tech Park. This is the first aircraft engine manufacturing plant in Vietnam, with an investment of over 200 million USD and plans to expand to 260 million USD. The plant was invested in two phases and has been operational, generating revenues of 140 million USD (over 3,400 billion VND) in 2023. Hanwha’s plant has high expectations, as aircraft engine production will be a major step for our manufacturing industry.

In addition to the Korean enterprise, other major corporations have expressed their intention to invest in this industry in Vietnam, including Mitsubishi, Universal Alloy Corporation (UAC), Airbus…

Mitsubishi is the second name after Artus Vietnam and the first major industrial corporation to establish an aircraft component manufacturing plant in Vietnam. In 2007, through its subsidiary MHI Aerospace Vietnam, the corporation invested in a plant in Thang Long Industrial Park with an initial capital of around 7 million USD on an area of 19 hectares. The plant has the functions of repairing, manufacturing, and processing aircraft wings and some other components, officially put into operation from June 2009.

Mitsubishi’s aircraft component manufacturing plant in Vietnam (Photo: SPS)

In addition to Mitsubishi, another Japanese enterprise, Nikkiso, also built an aircraft component manufacturing plant – mainly carbon fiber composite doors. Nikkiso’s plant in Vietnam is located in Hung Yen province with a total area of about 28.5 hectares; the number of plants increased to 5 by 2017.

Initially, Nikkiso’s plants in Vietnam mainly served Boeing 777 aircraft, but later they also served many other companies, notably Airbus. Since 2014, some parts of Airbus aircraft have been processed by Nikkiso at its plants in Vietnam. Nikkiso is a strategic component supplier for Airbus in recent years, especially for the popular A320 aircraft.

Nikkiso’s manufacturing plant (Photo: Thang Long II Industrial Park)

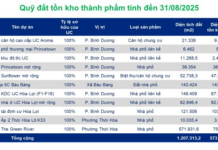

In 2022, UAC Group from the US became the next enterprise to invest in an aircraft component manufacturing plant in Vietnam through its subsidiary in Da Nang. The total investment capital of the project is 170 million USD and has been in operation since Phase 1 from March 2020 with an area of up to 170 hectares.

The plant has a capacity of nearly 12,500 tons of finished products per year, supplying components to the two largest aircraft manufacturers in the world, Boeing and Airbus, with various product lines from Boeing 787, 777 to Airbus A350, A330, A320…. The finished products from the plant are exported to foreign markets such as Europe, America, and Malaysia…

UAC also plans to produce engines for Rolls Royce in Vietnam. The corporation has set a goal to export 25 million USD in 2021, 82 million USD in 2022, and over 180 million USD by 2026.

UAC’s aircraft component manufacturing plant (Photo: Official Website of Da Nang City)

Most recently, KP Aero, a Korean company, also announced that it will invest 20 million USD in building a plant in Vietnam to supply aircraft components for Boeing in Da Nang. In addition, Airbus also mentioned expanding its supply chain in Vietnam through a partner, due to the high demand for aircraft parts.

From the Vietnamese side, Aerospace Engineering Services Joint Stock Company (AESC), headquartered in Quang Minh Industrial Park (Hanoi), was recommended by the Civil Aviation Authority of Vietnam to the Ministry of Transport to introduce Airbus in developing the aerospace industry in Vietnam.