The world’s most exceptional athletes will, this summer, receive their Olympic and Paralympic gold medals on podiums made from… garbage. More specifically, they are recycled food boxes produced by a small factory on the outskirts of Paris by the startup, Le Pavé. This is a first for the Olympics, with the podiums being made from 100% recycled plastic.

“There is too much plastic that is harmful to the environment. If it can be reused, it will create an economic resource,” says Maurius Hamelot, 29, co-founder of Le Pavé. According to The New York Times, Le Pavé manufactured 11,000 seats for spectators at two sports arenas. All were recycled from used shampoo bottles and millions of colorful bottle caps.

A few years ago, Le Pavé only had three employees. After an unexpected call from the Olympic organizers, the company had the opportunity to sign a new contract, expand to 34 employees, and put two new factories into operation. This has become a model for the Paris Olympic Committee, which is committed to making this year’s Olympics the greenest in history.

Le Pavé has worked with 50 local recycling companies to collect used plastic.

Le Pavé is a testament to France’s increasingly dynamic startup culture, spurred by ambitious policies from President Emmanuel Macron to transform the economy with new industries focused on clean technology and green transition.

“We are a new type of industrial startup, focusing on environmental needs, and our goal is to become a leading company in Europe,” says Jim Pasquet, 31, co-founder of Le Pavé.

Co-founder Hamelot has been working to convert plastic waste collected from Paris neighborhoods into high-quality components. As an architecture student at the University of Versailles, he set his sights on the construction industry, one of the largest carbon emitters. “What’s common in construction is waste, and waste is everywhere in the world. How do you recreate construction materials without harming the environment?”

Hamelot told The New York Times that he bought a used pizza oven and began experimenting with melting plastic waste from electronic scraps, including old coffee machines and cell phones. In 2018, he and Pasquet, childhood friends, founded Le Pavé and won a series of innovation contests. This gave them the opportunity to enter La Ruche, an incubator in Paris specializing in social enterprises, digital technology, crafts, and culture.

Le Pavé used 100 tons of recycled bottles and caps to make panels for 11,000 seats.

By 2019, Le Pavé was granted a patent for its thermal compression molding technology. Soon after, Hamelot received a call from Solideo, the French company overseeing infrastructure for the 2024 Olympics. The organizers, aiming to halve emissions compared to previous Games, asked if Le Pavé could produce 11,000 seats for the Olympic Aquatic Center under construction. “It was a fantastic opportunity,” says Pasquet.

Hamelot and Pasquet then worked with 50 local recycling companies to collect used plastic, tested dozens of prototypes, and checked for durability before signing the final agreement with Solideo in 2022.

Embracing the philosophy that local action can have a significant social impact, the company decided to hire employees from Seine-Saint-Denis, including long-term unemployed and refugee individuals. Approximately 1,700 students were engaged to collect 1 million yellow bottle caps to decorate the stadium seats.

As mentioned, Le Pavé used 100 tons of recycled bottles and caps to make panels for 11,000 seats. To create the silver panels for the 68 Olympic podiums, Le Pavé utilized 18 tons of recycled plastic and polystyrene food boxes.

While the recycling process itself generates carbon emissions, according to Pasquet, it still emits far less carbon dioxide than using virgin plastic.

To create the silver panels for the 68 Olympic podiums, Le Pavé used 18 tons of recycled plastic and polystyrene food boxes.

“We are creating something beautiful out of old waste,” he says.

Le Pavé is opening a second small factory in the Burgundy region of eastern France and is raising funds to open two more factories in the west and south. As the government seeks to reindustrialize France, Le Pavé’s goal is to create jobs by opening small factories. The co-founder believes that the old model of large factories will not meet today’s environmental and social challenges.

“We want this to become the new color of the industry, breaking free from the old image,” he says.

Recently, the Élysée Palace, the official residence of the president, installed a decorative wall made by Le Pavé. The company is also producing flooring for major French furniture retailers and is pushing ahead with projects to produce wood-like flooring for buildings.

“We see ourselves with the opportunity to build something that will last for many years. Something very big,” says Hamelot.

According to: The New York Times

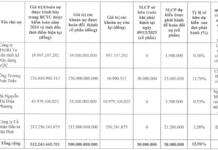

What’s Left for Vietnam’s Plastics Tycoon Tran Duy Hy After Selling 70% of Duy Tan Plastics to SCG?

After having sold his entire core business to SCG in 2021, entrepreneur Tran Duy Hy started a new business venture in the recycled plastics sector through two flagship companies, Duy Tan Recycled Plastic located in Long An and Plascene based in California, USA. According to Le Anh, the representative of Duy Tan Recycled Plastic, the company is still struggling with losses.