According to the Hanoi Department of Industry and Trade, the city boasts 47 traditional trades out of the 52 in the country, with 1,350 craft villages and trade villages. This includes 39 villages specializing in lacquerware and mother-of-pearl inlay, 365 in bamboo and rattan weaving, 170 in timber processing, 5 in ceramics, 62 in conical hat and leaf hat making, 78 in metalworking, 13 in carving and sculpture, 4 in gold leaf and gold foil, 5 in net weaving, 138 in embroidery and lace-making, 152 in textile and garment manufacturing, 12 in leather and shoe-making, 5 in paper votive offering production, and 159 in agricultural product processing. The remaining 143 villages are engaged in other trades.

Hanoi takes the lead in the country with 1,350 craft villages, over 800 of which specialize in handicrafts. Reports from the city’s communes and wards show that the total revenue from 337 traditional craft villages and trade villages exceeded VND 20,000 billion. Some handicraft villages have high revenues, such as the Son Dong artistic carving village in Hoai Duc district, with revenues of over VND 3,000 billion, and the Huu Bang carpentry village in Thach That district, with revenues of over VND 1,000 billion. Hanoi’s exports of handicraft products reached over USD 200 million as of September 2024, an increase of 8% compared to the same period in 2023.

LACK OF RAW MATERIAL SELF-SUFFICIENCY

According to the latest survey by the Hanoi Center for Industry Promotion and Industrial Development Consulting, in areas with a high concentration of craft villages specializing in ceramics, lacquerware, bamboo and rattan weaving, and woodwork, the average annual consumption of raw materials is approximately 6,800 tons for bamboo and rattan villages, 620,000 tons for ceramic villages (mainly clay and kaolin), 4,000 tons for lacquerware villages, and over 1,000,000 cubic meters of wood for woodwork villages.

However, at the “Conference on Connecting Supply and Demand of Raw Materials for the Handicraft Industry between Hanoi and Northern Provinces” held on August 2, Eminent Artist Dao Viet Binh, Chairman of the Kim Lan Ceramic Association, shared that the annual demand for raw materials for ceramic products is quite high. For example, they require approximately 80,000 tons of clay and kaolin, 10,000 tons of feldspar and quartz, and 3,000 tons of glaze and additives.

However, most of these raw materials have to be sourced from provinces outside of Hanoi, such as Phu Tho, Quang Ninh, and Lao Cai, or imported from other countries. The supply chain for ceramic raw materials is also inadequate due to its reliance on intermediaries, and there is no direct purchasing system between the extraction sites and the production sites. It is challenging to access high-quality clay and kaolin mines as they are often sold to foreign companies at higher prices than what local enterprises can offer.

Additionally, raw material prices fluctuate significantly, and there is a lack of long-term stable contracts. Transportation costs are high due to the absence of specialized logistics chains, and the quality of raw materials is inconsistent, affecting the quality of the final products and increasing the defect rate. Certain raw materials, such as special color glazes, zircon, and refined metal oxides, need to be imported at high prices, increasing production costs and making it difficult to compete in the market.

Mr. Nguyen Vinh Quang, Chairman of the Phu Xuyen Mother-of-Pearl Inlay Association in Hanoi, also mentioned that the primary raw material for mother-of-pearl inlay is shells and oysters from the sea. However, this resource is becoming increasingly scarce and expensive due to over-exploitation in the past and biodiversity conservation regulations. This directly impacts production costs, raising product prices and reducing competitiveness in the market. Moreover, the inconsistent quality of raw materials poses challenges for artisans in selecting and treating the materials to create perfect artworks.

In the field of lacquerware, Ms. Nguyen Thi Hoi, Chairman of the Ha Thai Lacquerware Association, shared that 80% of their raw materials have to be sourced from outside the province, leading to unstable supply, high transportation costs, and a lack of production autonomy due to reliance on intermediaries.

BUILDING A NETWORK OF INTER-REGIONAL RAW MATERIAL SUPPLY CONNECTIONS

To address these challenges, Mr. Dao Viet Binh proposed a solution focusing on inter-regional raw material and production linkages. This involves establishing strong connections between provinces with raw material sources and Hanoi’s ceramic craft villages, encouraging long-term supply contracts to reduce market fluctuation risks, developing logistics and warehouse infrastructure, such as constructing raw material transshipment warehouses in the Gia Lam area, and digitizing logistics management for transparent operational costs.

Additionally, it is recommended to encourage enterprises to invest in raw material preprocessing and refining workshops, collaborate with research institutes and universities to improve technology and analyze raw material quality, and provide financial and credit support to enterprises. This includes offering preferential loans to production facilities for expanding their raw material warehouses and providing tax and land incentives, as well as transportation subsidies, to domestic raw material suppliers.

Ms. Hoi suggested that Hanoi establish a formal and stable raw material supply chain by building an inter-regional raw material supply network connecting Hanoi with provinces like Phu Tho, Tuyen Quang, Nghe An, and Thanh Hoa. This network should aim to develop stable raw material supply regions with stringent technical standards.

According to Mr. Le Ba Ngoc, Vice Chairman and General Secretary of the Vietnam Handicraft Exporters Association, raw materials for handicrafts are a significant issue for craft villages. “We depend on Thanh Hoa for bamboo, Son La and Hoa Binh for rattan, Hue and Quang Nam for bamboo, and Kon Tum and Lam Dong for wood. If these provinces do not have a raw material planning system, it will be challenging for Hanoi to find suppliers. Therefore, we need to foster intra-regional connections and inter-regional linkages,” said Mr. Ngoc.

In addition to creating raw material regions, Mr. Ngoc believed that linkages should also focus on creating transparent raw material sources through processing. He advocated for a cooperative approach involving the public sector, private enterprises, and communities, as import markets now trace products to their origins. “If we can achieve these goals, we will solve the raw material issue and maintain the competitiveness and development of our craft villages,” he added confidently.

The Incomplete Billion-Dollar Project: A Decade-Long Saga in Hanoi

In May 2014, construction began on a road surrounding the Chu Van An Memorial. With a projected completion time of 36 months, this project aimed to enhance the accessibility and prominence of the memorial site. However, over a decade later, the project remains unfinished, with land acquisition at the Phan Trong Tue intersection posing a significant challenge and delaying its completion.

The Capital’s Affordable Housing Push: Hanoi Approves 179 Hectares for Four Low-Cost Housing Projects in Dong Anh District

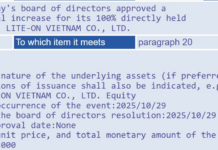

Four social housing projects in Dai Mac, Tien Duong, and Kim Chung (Dong Anh District, Hanoi) have just been approved for land-use plans for 2025, spanning a total area of nearly 179 hectares.