Tightening Procedures and Standardizing Durian Production Chains

On August 4th, Mr. Tran Thanh Nam, Deputy Minister of Agriculture and the Environment, signed and issued the “Procedure for Food Safety Control for Fresh Durian Fruit Exports.” This is the first national-level guidance document to synchronize and unify the entire production and business process of a billion-dollar agricultural product.

The new procedure specifies the food safety control requirements from cultivation, harvesting, transportation, storage, packaging to export. All organizations and individuals involved in the chain, including traders not directly involved in production or packaging, must comply with the procedure and are subject to the supervision of local competent authorities. This is a new approach to ending the evasion of responsibility in cases where goods are rejected at import ports.

Tightening procedures and standardizing durian production chains.

Growing facilities must fully meet food safety requirements, have traceable origins, and be capable of product recall if quality issues arise. Similarly, packaging facilities must also meet hygiene and traceability standards and have codes and certificates as stipulated by the Ministry. Transportation and storage from growing areas to packaging facilities must also ensure synchronization in food safety conditions.

Notably, the procedure allows for three forms of food safety certification for growing areas: certification according to domestic or international standards (GAP, HACCP, ISO…), periodic commitment and inspection, or certification according to current regulations. This adds flexibility, considering the small-scale and dispersed nature of Vietnam’s durian industry.

Additionally, the procedure clearly defines the roles of management agencies, providing a more transparent, synchronized, and professional legal framework for the durian industry.

Opportunities Come with Adaptation Pressures

Framing the entire industry within a set of standards will exert pressure on each link in the production chain. Failure to meet requirements at the growing or packaging stages will result in the entire chain being denied clearance.

Consequently, businesses and cooperatives lacking adequate traceability management and internal control systems will need to invest in both human resources and storage and monitoring systems. Even traders accustomed to traditional oral transactions will have to adapt to meet traceability requirements and assume legal responsibility for any violations.

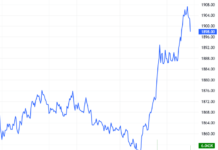

With durian exports continuously surging, surpassing $2.1 billion in 2024 and potentially reaching $3 billion this year, now is the opportune time to bring this product into a structured framework.

Each link in the production chain must standardize to adapt and maintain its market position. This foundation will also enable Vietnamese durian to target more demanding markets in the future.

The Magic of Saigon’s Retail Renaissance: Unlocking a 30-40% Sales Surge

As we approach the Lunar New Year of 2025, the Year of the Snake, businesses are gearing up with an impressive capital of over 22 trillion VND. Notably, more than 8 trillion VND of this is allocated for essential food and beverage items, ensuring a well-stocked and prosperous holiday season.

Transforming Untraceable Food into Thousands of Labeled Packages

The Hanoi Market Management Bureau has uncovered a string of suspicious food products, indicating a surge in smuggled goods. In a concerning trend, these illicit operators are transforming untraceable, floating goods into labeled products, misleading consumers and undermining legitimate businesses. This discovery underscores the critical need for heightened vigilance and stringent measures to curb such deceptive practices and protect public health and safety.

![[On Seat 07] MG – From a Widely Criticized Car Brand to Impressive Sales Figures and the Opportunities for MG7 in Vietnam](https://xe.today/wp-content/uploads/2024/08/v-quote-te-3-100x70.jpg)