Tightening Procedures and Standardizing Durian Production Chains

On August 4th, Mr. Tran Thanh Nam, Deputy Minister of Agriculture and Environment, signed and issued the “Food Safety Control Procedure for Fresh Durian Exports.” This is the first national-level guidance document to synchronously control and unify the entire production and business process of agricultural products, generating a value of billions of dollars annually.

The new procedure specifies food safety control requirements from cultivation, harvesting, transportation, storage, packaging to export. All organizations and individuals involved in the chain, including traders not directly involved in production or packaging, must comply with the procedure and are subject to the supervision of local competent authorities. This is a new point to end the responsibility avoidance when the goods are rejected at the import port.

Tightening procedures and standardizing durian production.

Cultivation bases must fully meet food safety requirements, have traceable origins, and be capable of product recall if quality issues arise. Similarly, packaging facilities must also meet hygiene and traceability standards and have codes and certificates as stipulated by the Ministry. Transportation and storage from growing areas to packaging facilities must also ensure synchronization in food safety conditions.

Notably, the procedure allows for three forms of food safety certification for growing areas: certification according to domestic or international standards (GAP, HACCP, ISO…), commitment and periodic inspection, or obtaining food safety certification as per current regulations. This increases flexibility, catering to the small-scale and dispersed nature of Vietnam’s durian industry.

Additionally, the procedure clearly defines the roles of management agencies, providing a more transparent, synchronized, and professional legal framework for the durian industry.

Opportunities Come with Adaptation Pressure

Framing the entire industry will exert significant pressure on each link in the production chain, as failing to meet requirements at the cultivation or packaging stage can lead to the entire chain being denied clearance.

Therefore, businesses and cooperatives lacking traceability management capabilities and internal control systems will have to invest in both human resources and storage and monitoring systems. Even traders, accustomed to traditional oral transactions, will have to adapt to meet traceability requirements and assume legal responsibility for any violations.

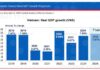

With the continuous strong growth of durian exports, surpassing $2.1 billion in 2024 and potentially reaching $3 billion this year, this is an opportune time to bring the product into a structured framework.

Each link in the production chain must standardize to adapt and maintain its market position. This foundation will also enable Vietnamese durian to target more demanding markets in the future.

The Ultimate Guide to the King of Fruits: Unveiling the Secret to Mastering the Art of Durian Cultivation

The recently introduced food safety control protocol for durian exports is a game-changer for the industry. It not only brings structure and order but also empowers durian producers to elevate their game. With this new framework in place, the industry can now aim for higher quality standards and sustainable growth in the international arena.