A quiet cafe in the heart of bustling Saigon was the setting for our meeting with Mr. Ton Thanh Nghia, the CEO of Ton Van and affectionately known as the “Button King” of Vietnam. With a humble demeanor and a rich life story to tell, he shared his journey over a cup of coffee.

Mr. Nghia gained fame on social media after appearing on Shark Tank Vietnam with his daughter, Ton Nu Xuan Quyen. In person, he is down-to-earth and friendly, punctuating his stories with a gentle cough, a reminder that time is precious and his entrepreneurial journey has been full of challenges. At 68, he is contemplating retirement and passing on his legacy to the next generation.

As he sipped his coffee, he recounted his life story, with its sweet and bitter moments, leaving a lasting impression.

Mr. Nghia shared his early life and career choices, including his engineering degree and work as an interpreter for a Japanese company.

With a degree in Hydraulic Engineering from Ho Chi Minh City University of Technology and a job as an interpreter, what inspired you to start your own business and create your own product?

After graduating, I worked as a hydraulic engineer for a state-owned company for ten years. My work took me to remote border areas, 150 km away from home, with difficult road conditions. I could only return home a few months, leading to a sense of isolation.

My meager income barely covered my expenses, let alone supporting a family. The burden of making ends meet weighed heavily on me for years. Finally, I made the difficult decision to resign, a choice that involved a long internal struggle. In 1986, I moved to Saigon, just as the country was opening up. The bustling atmosphere and influx of foreign businesses made me realize that opportunities were within reach. I decided to learn foreign languages to escape my predicament, starting with English and then Japanese.

In 1990, a Japanese company offered scholarships and comprehensive training. I was one of ten people selected for the program and studied diligently for a year. However, only five of us were hired after the exam, and I was not among them. At 35, holding the rejection in my hands, I was heartbroken. I begged the school to let me stay for another six months, studying Japanese with a younger class, clinging to a glimmer of hope. As I contemplated my uncertain future, a Japanese company hired me through a teacher’s recommendation. They offered a three-month trial, but after a month, they let me go, citing insufficient capabilities.

Yet, as one door closed, another opened. Through friends’ introductions, I found employment with another Japanese company. This time, they not only provided professional training but also discreetly assessed my morals and character. After passing their tests, I was officially hired with a salary of 500 USD/month, a substantial sum at the time.

However, after three years, when the company was running smoothly, I felt uninspired. I thrive on challenges and navigating through storms, but once things became calm and orderly, I lost my motivation.

So, at 37 or 38, I left. Others may have called it foolish, but for me, it was the beginning of a new path—a path of my own making.

Mr. Nghia shared his reasons for choosing to focus on small but unique products like buttons, even when the market was less familiar with high-end accessories and exports.

28 years ago, when the Vietnamese market was less focused on high-end accessories and exports, what inspired you to choose something as small and seemingly insignificant as buttons for your career path?

Sometimes, a profession chooses you, rather than the other way around. While working at my previous company, I noticed a market demand that wasn’t being met. With my engineering background and connections, I saw that the machinery for producing buttons wasn’t overly complex.

However, using plastic as a raw material would result in ordinary, mass-produced buttons with no distinctiveness. I wanted to find a different path. That’s when the idea struck me—why not make buttons from seashells, which are often discarded on beaches? With careful craftsmanship, these shells could be transformed into shimmering buttons, carrying the essence of the sea. Each shell, whether white or iridescent, holds the story of a fisherman’s hard work. I wanted to provide additional income to these fishermen, lightening their burden.

Of the ten classmates from the language program, all have achieved success. They have not only enriched themselves but also contributed to the country’s economy and infused society with new energy during this period of openness. Looking back, I see that we each took a different path, but we all share a spirit of conquest.

Mr. Nghia reflected on the challenges of starting a business, comparing it to polishing a gem from a pebble.

If you were to compare your entrepreneurial journey to “polishing a gem from a pebble,” what do you consider the most difficult aspect of the initial phase?

I started my business with a meager capital of just one gold bar. While others may have doubted my ability to compete with international companies, I remained confident due to my technical background. I understood the machinery and was determined to improve it.

I imported some equipment from Italy and then modified it to suit local production, adjusting everything from the needles to the speed and fine details. Initially, I worked tirelessly with traditional machines, conducting experiments and gaining experience. It wasn’t until five years later that I had the capital and knowledge to invest in more modern equipment.

In the beginning, I also lacked the funds to build a proper factory, so I made do with a stuffy and cramped attic space in my own home, measuring only a few dozen square meters. This makeshift workshop served as both a production area and living quarters for seven workers, all from my hometown of Quang Nam, who had come to Saigon to pursue their dreams.

The most significant challenge wasn’t financial or mechanical but in finding customers. I traveled far and wide, knocking on the doors of industrial zones and large garment factories to introduce my products. However, everyone turned me down. They were accustomed to plastic buttons, which were cheap, common, and convenient, and they weren’t interested in switching to buttons made from seashells, despite their uniqueness and the story they carried.

Opportunity came when I decided to focus on foreign markets. It took years to find partners, but during this process, I connected with Japanese friends. After successfully completing the first order, I gained the trust of my partners, who then introduced me to other businesses. Orders started coming in from Japan, followed by Germany, Austria, the US, and Taiwan. My reputation spread, and my products found their way into the global market.

Having achieved success early on, what other challenges or crises has Ton Van faced since then?

I started my business in 1997, and just two years later, the world was shaken by the SARS outbreak. The situation was suffocating and terrifying, with countries closing their borders, grounding flights, freezing tourism, and paralyzing trade. International fairs and exhibitions fell silent.

For an entire year, our company weathered the storm, followed by a wave of economic crises. I suffered from insomnia, desperately seeking ways to retain my workers. I didn’t want to let anyone go because I knew that behind each employee was a family relying on that income. During this difficult period, I sent some workers to work temporarily at a friend’s company. The remaining workers struggled to keep the business afloat with the few orders we had. There was a time when we could only operate four days a week.

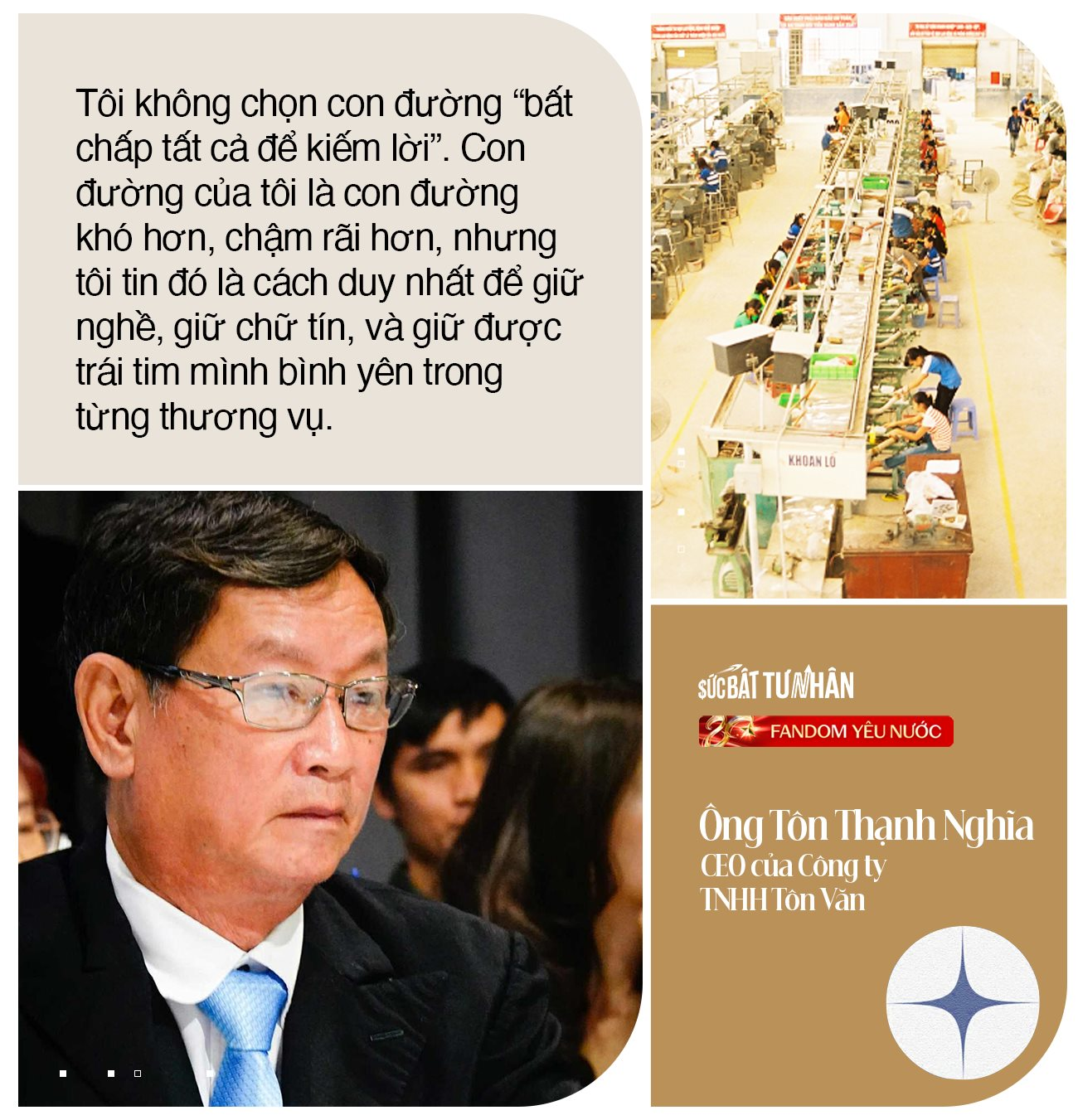

In 2007-2008, the world was again plunged into a financial crisis. During this time, I decided to build a new factory on a newly purchased plot of land. People were surprised by my decision, asking, “Are you building a factory now, in the midst of such difficulties?” But I believed that a strong foundation was necessary to withstand the storms ahead. The land spanned 10,000 square meters, with a 3,000-square-meter factory. In addition to the production area, there were dormitories and common areas for workers, providing a sense of home and encouraging long-term commitment.

Mr. Nghia shared the challenges of using seashells, a seemingly simple material, to create high-end products for renowned fashion brands like Dior, Escada, and Ralph Lauren.

Using seashells, a seemingly simple material, to create high-end products for renowned fashion brands like Dior, Escada, and Ralph Lauren, you must have faced stringent requirements from your partners. Can you tell us about that?

Our partners had strict requirements, including standards for farming environments, seed quality, machinery, labor regulations, working conditions, and dye colors. Everything needed to be legally compliant and properly documented.

Once, we received an order from a Spanish partner who requested buttons with square holes for threading. It sounded simple, but it was a complex technical challenge. Traditionally, drilling holes requires a sharp, round drill bit. However, creating square holes defied the laws of mechanics.

The order was substantial and valuable, and I was overjoyed but also anxious. The challenge was immense, and I had to experiment, redesign the drill bits, calculate vibration angles, and modify the production line to produce a large quantity of high-quality buttons within a short time. This happened around the Tet holiday, when everyone else was preparing for the festivities, but we worked day and night alongside the machines.

Each challenging order required us to modify our equipment and incur additional costs. The pressure was intense, but our determination drove us forward. Finally, when the exquisite square-holed buttons were completed and our client expressed satisfaction, I felt a sense of triumph. It wasn’t just about a successful order; it was about the pride of Vietnamese craftsmanship.

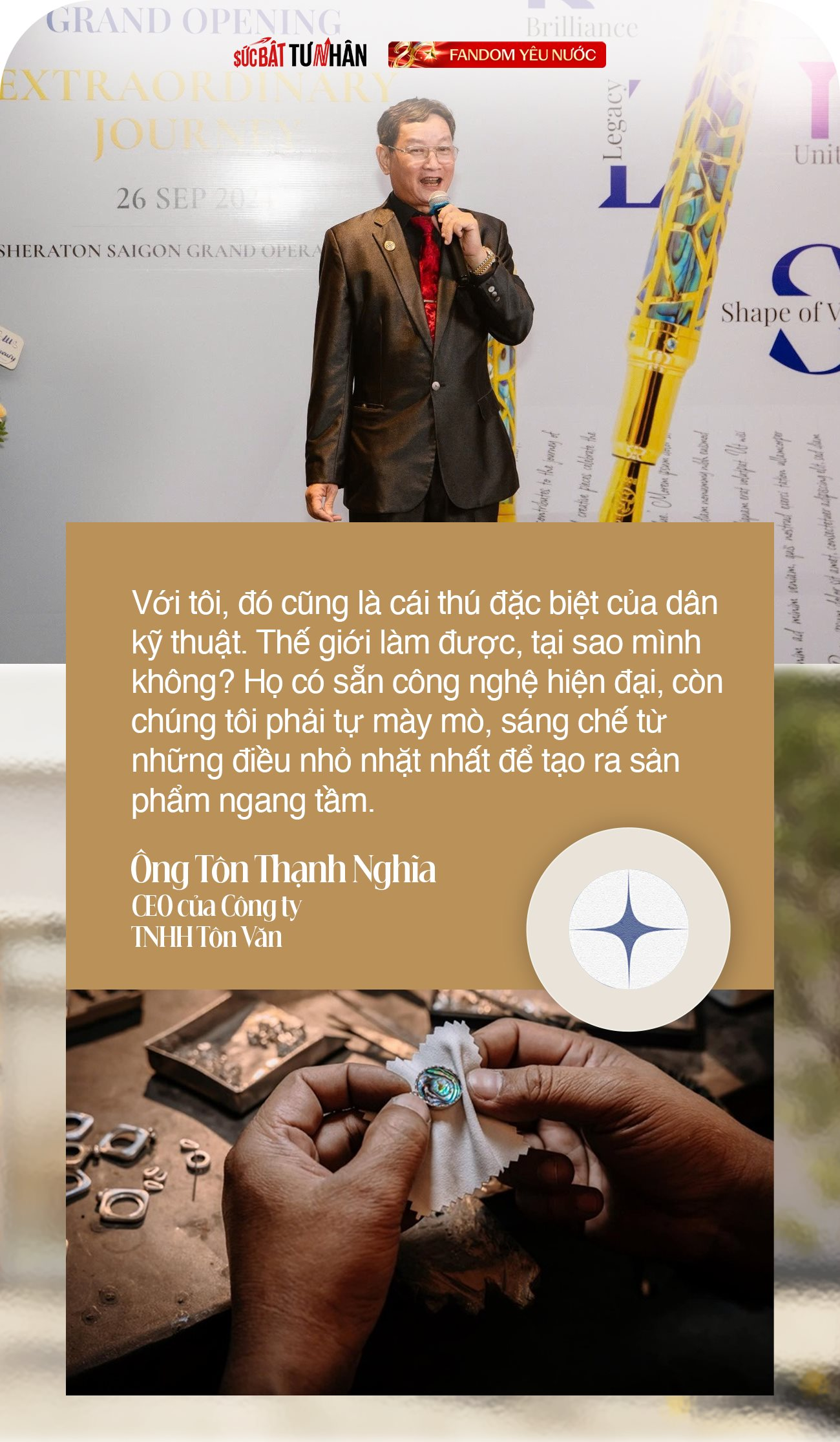

For me, this is the unique appeal of engineering. If something can be done elsewhere, why can’t we do it here? They may have advanced technology, but we have ingenuity and the drive to invent solutions from scratch to create products of equal caliber.

Mr. Nghia shared his thoughts on conquering the challenges of working with major fashion brands and exporting to demanding markets.

Having conquered challenges and worked with major fashion brands, exporting to demanding markets, what do you attribute your extraordinary success to?

There are two principles I hold dear. The first is ensuring quality. Once, a partner sternly canceled a contract and demanded the destruction of an entire batch due to subpar quality. The financial loss was significant, and emotionally, it was devastating. Starting a business and facing such a penalty is like stepping towards bankruptcy. At the time, I was angry and thought they were being difficult. However, I later realized they were right. Their strictness taught me a valuable lesson, ensuring that subsequent orders would not repeat the same mistake.

The second principle is upholding integrity. Especially when working with foreign partners, punctuality is crucial. They don’t accept excuses; they expect solutions. Delivering on time, every time, regardless of the challenges, is essential. This discipline has taught me that integrity is the passport to the world.

I still remember my partners’ words: “Signing a contract with Ton Van means we can sleep soundly.” My business philosophy has remained consistent: if we strive to do our best, profits will follow. I don’t choose the path of “doing whatever it takes to make a profit.” My path is more challenging and slower, but it’s the only way to uphold our craft, maintain integrity, and keep our hearts at peace with every transaction.

Mr. Nghia reflected on his journey of nearly 30 years, adapting to the changing landscape of the fashion accessory industry.

Looking back on your journey of nearly 30 years, how have you adapted and evolved with the changing landscape of the fashion accessory industry?

Every year, our partners have new requirements. They don’t just want traditional buttons; they want to infuse novelty into their products: engraving brand names, changing shapes and colors, incorporating stories into their collections, or creating diversity for special events.

To meet these demands, I had to invent and modify machinery to achieve both quantity and precision. However, most of my work still revolves around traditional buttons. In the ever-changing world of fashion, traditional buttons remain the foundation that cannot be replaced.

Besides producing buttons, have you ventured into other products or services?

I am always eager to conquer new challenges, but I prefer to do so quietly, without fanfare or excessive publicity. Every year, I set new goals to push myself. Currently, I am collaborating with my daughter to produce high-end pens as gifts. Each pen is not just a writing instrument but a work of art.

Additionally, I have dedicated time and effort to researching and producing kitchen utensils, such as spoons, forks, knives, and more, made entirely from natural seashells. These products bring the essence of the sea to the table, blending rustic charm with sophistication. Some of these creations have graced the tables of prestigious restaurants and hotels worldwide.

As a veteran in the business world, Mr. Nghia shared his advice for young entrepreneurs.

As a “veteran” in the business world, what advice would you give to young entrepreneurs?

Our ancestors often said, “Failure is the mother of success.” But in

“Turning Lead into Gold: The Power of Innovative Business Models”

“There are countless startups with brilliant ideas, exceptional capabilities, and passionate founders. However, if their creations are inefficient and ineffective, they will struggle to secure funding and succeed in the competitive business landscape.”

“Staying Local: Shark Phi Vân’s 3 Essential Lessons for Franchise Success”

In the latest episode of Shark Tank, Shark Nguyen Phi Van, a franchise expert, shared her insights on three key factors that contribute to the success of Vietnamese startups in the franchise business model. With her wealth of experience, Shark Van dived into the strategies that aspiring entrepreneurs can implement to make their mark in this exciting industry.

“A Daring Venture: The Audacious Quest for a Luxurious Fish Sauce”

“The enigmatic French uncle is poised to unveil the rationale behind seeking a substantial investment of half a million dollars for a 12.5% stake in his burgeoning enterprise. With an air of confidence, he readies himself to address the curious onlookers, armed with a persuasive narrative that promises to elucidate the strategic vision behind this audacious financial maneuver.”