September 4, 2025, marks a significant milestone for Hoa Phat Group in particular and the Vietnamese steel industry in general, as the second blast furnace of the Hoa Phat Dung Quat 2 steel complex project successfully produced its first batch of iron.

Illustration of a blast furnace. Image: Metallurgprom

This first batch of iron marks a crucial step in the completion of Phase 2 of the “Dung Quat 2 steel punch” project, worth VND 85,000 billion, by the Hoa Phat Group.

Currently, Hoa Phat operates a total of six blast furnaces, including four in Dung Quat 1 and two in Dung Quat 2, with a total capacity of 12 million tons of steel per year, including 9 million tons of high-quality hot-rolled coil (HRC) steel.

When Dung Quat 2 is fully operational, the Group’s steel production is expected to reach 16 million tons/year, propelling Hoa Phat into the top 30 steel companies worldwide.

How do the blast furnaces imported from the Netherlands save energy and reduce CO2 emissions?

As the largest steel producer in Southeast Asia, Hoa Phat has heavily invested in modern technology from Europe and the G7 countries.

For the second blast furnace in Dung Quat 2, Hoa Phat chose Danieli Corus, a company based in the Netherlands renowned for its advanced technology in iron and steelmaking, especially in blast furnace (BF) and oxygen steelmaking (BOF) technology.

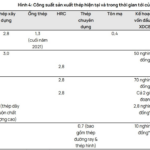

The second blast furnace, designed and manufactured by Danieli Corus, has a volume of 2,500m3 and can produce twice as much liquid iron as the furnaces at Dung Quat 1.

Image: Danieli Corus

Most importantly, this blast furnace consumes less energy and meets stringent environmental standards, particularly in reducing CO2 emissions, aligning with the global steel industry’s green transition goals.

Specifically, what has Danieli Corus done with its blast furnaces to align with its “Green Steel” vision, aiming for a 40% reduction in emissions in the BF-BOF chain?

First: Blast furnace design with high-efficiency cooling staves technology

Danieli Corus’ blast furnace design utilizes a cooling system with copper plates and high-conductivity graphite refractory material, ensuring long-term operability.

This design enables the furnace to operate with high efficiency and a long service life of over 25 years without major maintenance. It reduces overall energy consumption by optimizing gas and heat flow and minimizing heat loss.

A 2,623m³ blast furnace by Danieli Corus. Image: Danieli Corus

Second: Increased use of recycled metals and primary materials

The blast furnace is designed to increase the ratio of recycled metals such as scrap and direct reduced iron (DRI) in the charge mix, reducing the need for pure iron ore reduction and, consequently, lowering coke and coal consumption.

Additionally, this approach reduces CO2 emissions by up to 40% compared to traditional furnaces, as recycled metals require less carbon for reduction.

Third: Utilization of biofuels

Biofuels, such as biomass or wood coal, are primarily used in Danieli Corus’ blast furnaces. These fuels are produced from biomass, including wood, agricultural by-products, or organic waste through a thermal decomposition process.

By using these environmentally friendly fuels, the blast furnaces can partially replace coke or coal in the iron ore reduction process, reducing the reliance on fossil fuel extraction. In steelmaking, biofuels are considered carbon-neutral because the CO2 emitted during combustion is equivalent to the CO2 absorbed by biomass during its growth.

Thus, substituting coke with biofuels significantly reduces CO2 emissions from fossil fuels.

“Billionaire Tran Dinh Long Cheers as Hoa Phat Dung Quat Integrated Steel Mill Project Progresses”

The integrated complex has a total capacity of 12 million tons per year, including 9 million tons of hot-rolled coil (HRC) and high-quality steel. This state-of-the-art facility is a powerhouse in the steel industry, boasting an impressive output that caters to the diverse needs of our clients. With a focus on quality and efficiency, we ensure that every ton of steel that rolls out of our complex meets the highest standards, making us a trusted partner in the global market.

Should You Turn Off Your Fridge When Going on a Vacation? The Right Way to Do It and Save Energy.

With a few simple adjustments, families can significantly reduce their electricity bills without compromising on convenience or appliance longevity. By mastering the art of temperature control, embracing pre-travel cleaning rituals, and harnessing the power of energy-saving modes, households can take control of their electrical expenses while maintaining the efficiency and longevity of their beloved appliances.

Steel Giant Hoa Phat Avoids Anti-Dumping Duty on Hot-Rolled Coils in India

The Directorate General of Trade Remedies (DGTR) of India has announced its final conclusion regarding the anti-dumping investigation into hot-rolled coil (HRC) steel imports from Vietnam. As a result, HRC products manufactured by Hoa Phat Group Joint Stock Company (HOSE: HPG) will not be subject to anti-dumping duties.