This paradox presents the greatest economic barrier to green transition, while also raising core questions about the fairness of the current pricing system.

According to the IMF, global fossil fuel subsidies have reached $7 trillion, equivalent to 7.1% of world GDP, while businesses investing in recycling technology bear the full cost. This is an implicit “green tax” on sustainability efforts, making doing the right thing more expensive than doing the wrong thing.

The “Green Tax” Paradox: When Sustainability Efforts Are Punished by Pricing

The core paradox of the current circular economy is the complete reversal of pricing logic. A ton of recycled PET pellets costs more than virgin PET, despite the latter causing far greater environmental harm. Similarly, recycled polyester fiber from waste plastic bottles is more expensive than polyester made from crude oil. This is a market issue and a consequence of a distorted pricing system that does not fully account for externalities.

OECD research finds that the external costs of virgin products, including air and water pollution, community health deterioration, and biodiversity loss, are not factored into their price. This creates an unfair advantage for traditional production methods. For instance, a ton of virgin plastic from crude oil only reflects extraction, processing, and transportation costs, excluding pollution treatment, healthcare expenses from air pollution, or ecosystem restoration costs.

Fossil fuel energy subsidies play a pivotal role in distorting global prices. According to the IEA, consumer fossil fuel subsidies dropped to $620 billion in 2023 from a peak of over $1.2 trillion in 2022, but this figure remains enormous compared to recycling investment. When combined with implicit subsidies through the non-pricing of environmental harm, the total subsidy reaches $7 trillion, as estimated by the IMF.

This creates a “reverse tax” system that penalizes green behavior. While companies producing plastic from oil benefit from subsidized energy prices, recyclers must bear the full cost of collection, sorting, cleaning, and processing without equivalent support. This not only discourages investors but also sends a misleading signal to the market that pollution is economically “rewarded.”

UNEP’s “Making Peace with Nature” report emphasizes that accurate environmental impact pricing is key to transitioning to a sustainable economy.

However, in reality, most countries lack effective carbon pricing mechanisms. While there were 80 carbon pricing instruments globally in 2025, covering about 28% of global emissions, current carbon prices remain too low compared to the actual costs of environmental harm.

In Vietnam, this paradox becomes more pronounced as the government strongly promotes the Extended Producer Responsibility (EPR) program. According to Decree 08/2022/ND-CP, manufacturing and importing companies must contribute recycling fees to the Environmental Protection Fund. However, these fees are still insufficient to cover the actual recycling costs, creating a financial gap that makes recycled materials more expensive than virgin ones.

Unraveling the Hidden Costs of the Circular Economy and the Advantages of the Linear Economy

To understand the green cost paradox, a detailed analysis of the value chains of both models is necessary. The circular economy faces the challenge of a complex and costly “reverse supply chain,” especially in the dispersed collection phase.

This challenge is evident in Vietnam, where, according to a survey by a recycling company, the cost of collecting and pre-treating flexible plastic packaging is approximately 10,600 VND/kg. This is significantly higher than the proposed recycling support contribution (Fs), indicating that recyclers bear a substantial cost burden from the initial stage.

Sorting costs pose another barrier. While raw materials have uniform quality, recycled waste requires a complex sorting process. For PET plastics, sorting and cleaning to remove labels, caps, and other contaminants are considered one of the most intricate and expensive steps, directly impacting the final quality and price. Modern optical sorting technology can address this issue, but it demands high initial investment and operating costs.

Additionally, the recycling process faces quality challenges. The repeated heating process can degrade the polymer structure, resulting in recycled plastic with inferior strength and flexibility compared to virgin plastic. To achieve equivalent quality for technically demanding applications, businesses must invest more, increasing production costs.

In contrast, the linear economy has been optimized over decades, and the supply chain, from raw material extraction to the final product, has achieved economic efficiency due to massive production scales. According to the latest data, global plastic production has surpassed 400 million tons annually, creating economies of scale that small recycling facilities cannot match.

One-way logistics infrastructure also provides a clear cost advantage. Transporting raw materials from mines to factories and distributing products to consumers has been optimized over decades. In contrast, the reverse logistics of the circular economy is still in its infancy, with waste transportation costs from consumers to recycling facilities typically twice or thrice higher than those of raw material transportation.

This challenge is more complex in Vietnam. Despite lower labor costs, the dispersed and inefficient collection system has pushed up actual recycling costs. This situation has led to extensive policy consultations, where the business community, including international associations, expressed concerns that the proposed state recycling support rates might not reflect the actual costs compared to developed markets.

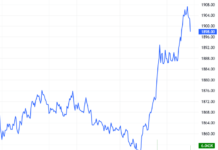

Market data from ICIS confirms this cost discrepancy. According to Q1/2025 data, the price of high-quality recycled PET pellets (rPET) in Europe reached €1,800/ton, creating a gap of nearly €600/ton compared to virgin PET.

Illustration

|

Policy “Bottlenecks” and Choices for Vietnamese Businesses

Vietnam’s EPR policy, although considered advanced in ASEAN, faces several “bottlenecks” in implementation. According to UNDP research on Vietnam’s EPR progress in 2024, the current contribution fee (F) is insufficient to create a sustainable secondary market for recycled materials.

Specifically, with the proposed fee for a 500ml PET bottle set at 61 VND, this amount equals only 1.62% of the product’s price, far too low compared to the actual recycling costs. When faced with the choice between expensive recycled materials and cheap virgin ones, businesses, especially small and medium-sized enterprises (SMEs), often prioritize short-term profitability.

A comparison with EU countries highlights a stark contrast. The EU implemented a plastic tax in 2021, charging €0.8/kg for non-recycled plastic packaging. This “stick” approach creates direct financial pressure on the use of virgin materials. Simultaneously, the EU has stricter EPR mechanisms with higher contribution fees than Vietnam.

Thailand also enforced a ban on providing free plastic bags at large retail chains from 2020 to change consumer behavior. Meanwhile, Japan introduced the “Top Runner” program, a unique mechanism that sets mandatory standards for the entire industry based on the most energy-efficient product on the market, fostering continuous innovation.

Vietnamese export businesses face increasing risks as the EU’s CBAM took effect in October 2023, with the initial reporting phase for steel, cement, fertilizer, and aluminum sectors. From 2026, companies exporting to the EU will have to pay carbon fees unless they can prove low emissions.

According to EuroCham Vietnam’s Whitebook 2025, European businesses in Vietnam struggle to meet ESG standards due to a lack of affordable and stable supplies of recycled materials. Many FDI companies have had to invest in building reverse supply chains or import recycled materials from abroad, increasing production costs.

This situation also impacts Vietnam’s Net Zero commitment. To achieve carbon neutrality by 2050, Vietnam needs to reduce greenhouse gas emissions by at least 15% by 2030. However, if the cost of recycled products remains higher than that of virgin ones, the transition will be slow and may fall short of the set goals.

From Policy to Corporate Strategy

To address the green cost paradox, Vietnam needs a comprehensive strategy to “level the playing field” between recycled and virgin products.

A carbon tax roadmap is a crucial macroeconomic solution. As per the government’s approved plan, Vietnam will pilot a carbon trading platform from mid-2025 to the end of 2028, involving major emitting industries like electricity, steel, and cement. While the price and revenue utilization mechanism are yet to be determined, this market is expected to create a carbon pricing tool, thereby promoting a shift towards low-emission technology.

Perfecting the EPR mechanism is a top priority. Experts suggest that the F fee should be adjusted flexibly based on actual recycling costs. For instance, for PET bottles, the fee should increase from the current 61 VND to 150-200 VND to cover collection and recycling expenses. Additionally, there should be a mechanism to differentiate fees according to recycling complexity, encouraging producers to design more easily recyclable products.

| The figure of “150-200 VND/bottle” is calculated based on the actual recycling costs per kg provided by industry players at policy workshops. Specifically, actual recycling costs range from 10,600 to 34,000 VND/kg. With an average PET bottle weight of 14g, the recycling cost per bottle falls between 150 and 476 VND. |

From a business perspective, value chain collaboration is key to optimizing costs. The recycling alliance model, such as the Vietnam Packaging Recycling Alliance, which includes major companies like Unilever, Coca-Cola, and Nestlé, has proven effective in sharing infrastructure investment costs. Expanding this model to other sectors like textiles and electronics could reduce recycling costs through economies of scale.

The role of green financing is also increasingly important. While the State Bank has provided guidance to channel capital towards sustainable sectors, access to preferential capital largely depends on individual commercial bank programs.

Some banks have launched green credit packages with interest rates 1-2% lower than usual to support businesses investing in recycling technology.

The Asian Development Bank (ADB) has committed $100 billion for climate finance from 2019-2030, with Vietnam as a priority. ADB’s Energy Transition Mechanism (ETM) with a 1:5 leverage ratio can potentially generate $15 billion in new green finance for projects in the region.

Lastly, strengthening consumer awareness through education and communication about “green value” is crucial. When consumers are willing to pay 10-15% more for sustainable products, businesses will have a stronger incentive to invest in recycled materials. VCCI’s Sustainable Business Assessment Program, with 153 evaluation criteria, can be expanded to include the use of recycled materials, creating positive market pressure.

[1] https://www.imf.org/-/media/Files/Publications/WP/2023/English/wpiea2023169-print-pdf.ashx

[2] https://www.oecd.org/content/dam/oecd/en/publications/reports/2023/11/new-aspects-of-epr-extending-producer-responsibility-to-additional-product-groups-and-challenges-throughout-the-product-lifecycle_84483c40/cfdc1bdc-en.pdf

[3] https://www.reuters.com/sustainability/trillion-dollar-question-fossil-fuel-subsidies-2024-11-15/

[4] https://sferaproyectoambiental.org/wp-content/uploads/2021/02/making-peace-with-nature-unep.pdf

[5] https://www.worldbank.org/en/news/press-release/2025/06/10/global-carbon-pricing-mobilizes-over-100-billion-for-public-budgets

[6] https://thuvienphapluat.vn/ma-so-thue/bai-viet/doi-tuong-nao-phai-dong-gop-tai-chinh-vao-quy-bao-ve-moi-truong-viet-nam-de-ho-tro-cac-hoat-dong-xu-843574-202501.html

[7] https://provietnam.com.vn/tin-tuc/dinh-muc-chi-phi-tai-che-fs-thap-se-khong-dat-duoc-muc-tieu-kinh-te-tuan-hoan/

[8] https://www.statista.com/statistics/282732/global-production-of-plastics-since-1950/

[9] https://www.recyclingtoday.com/news/europe-recycled-pet-plastic-higher-cost-compared-virgin-material/

[10] https://vietnamnet.vn/en/enterprises-anxious-about-proposed-recycling-fees-2173044.html

[11] https://wts.com/global/publishing-article/20250612-plastic-taxation-europe-update-2025~publishing-article

[12] https://en.vneconomy.vn/eurochams-2025-whitebook-launched.htm

[13] https://vietnamnet.vn/en/vietnam-embraces-circular-economy-to-tackle-waste-crisis-and-drive-green-growth-2420792.html

[14] https://thuvienphapluat.vn/phap-luat-doanh-nghiep/bai-viet/viet-nam-se-thi-diem-san-giao-dich-carbon-tu-2025-va-van-hanh-chinh-thuc-vao-2029-10611.html

[15] https://vietnamnet.vn/en/enterprises-anxious-about-proposed-recycling-fees-2173044.html

[16] https://vietnamnews.vn/economy/1655225/adb-cements-its-support-for-viet-nam-on-its-move-to-becoming-a-green-economy.html

[17] https://en.vcci.com.vn/sustainable-business-assessment-programme-in-2024-launched

– 12:00 13/09/2025

“VNG’s Impressive Performance in H1 2025: Soaring Profits, Revenue Surpasses VND 4.8 Trillion”

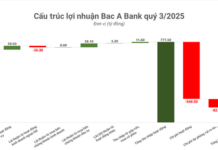

VNG Group has unveiled its financial report for the first half of 2025, boasting impressive figures. The company witnessed a remarkable 11% surge in revenue, totaling VND 4,803 billion, compared to the same period in 2024. Despite undergoing significant restructuring, VNG Group’s pure profit from business activities stood at an impressive VND 435 billion.

“Biofuel Plant Revitalization: The Road to November 2025”

With a tightly controlled schedule and maximum mobilization of resources, the Dung Quat biofuel plant is on track to officially restart ethanol production for E10 biofuel blending by November 2025.