Vietnam’s Automotive Production and Consumption Trends

On September 18th, the Government’s Electronic Information Portal hosted a seminar titled “Localization in the Automotive Industry for an Independent and Self-Reliant Economy.”

During the seminar, Dr. Nguyen Van Hoi, Director of the Institute for Strategy and Policy Research under the Ministry of Industry and Trade, revealed that in 2024, Vietnam’s total vehicle consumption reached 580,000 units, including both imported and domestically assembled vehicles. With an annual growth rate of 12-15%, projections indicate that the market could reach 900,000 to 1 million vehicles by 2030-2035.

However, Dr. Hoi noted that Vietnam’s vehicle imports remain significantly high. In 2024, imports totaled 172,000 vehicles, a substantial figure compared to other countries. For instance, Thailand produces 2 million vehicles annually but exports 1 million.

Dr. Hoi highlighted a persistent challenge over the past 30 years: Vietnam’s low localization rate in automotive manufacturing. The target for 2020 was 40%, but the current rate stands at only 10%, falling short of both localization and technology transfer goals.

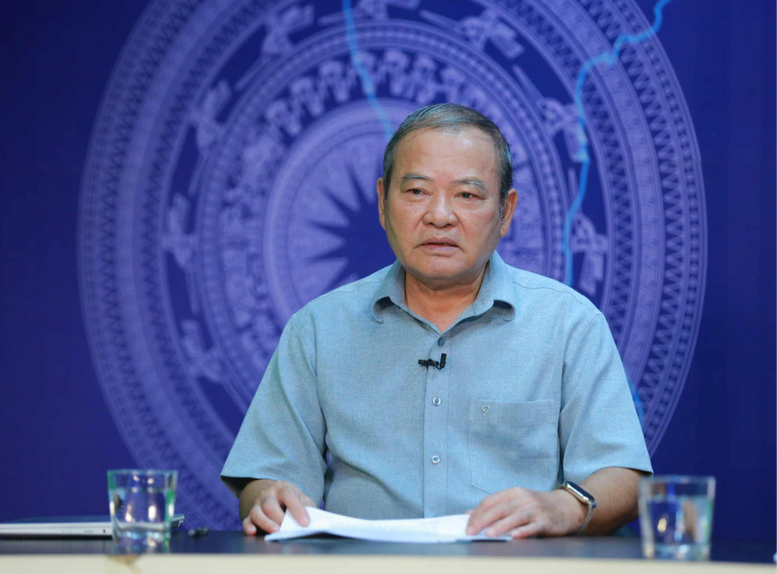

Dr. Ngo Nhat Thai. Photo: VGP/Minh Khoi.

Adding to the discussion, Dr. Ngo Nhat Thai, an expert with over 30 years of experience in automotive manufacturing, pointed out that Vietnam’s vehicle production volume is low and fragmented across multiple brands, making domestic component production nearly unfeasible.

Major brands like Toyota and Ford already have their global supply chains (OEM), making it difficult for Vietnamese businesses to enter without policies mandating foreign partners to establish local operations. Meanwhile, domestic enterprises struggle to build their own supply systems or rely on imported components. Therefore, policies should focus on attracting and compelling foreign investors to form joint ventures or establish component manufacturing plants in Vietnam.

“Automotive manufacturers must prioritize localization to reduce costs and enable exports. Current domestic prices are already high, significantly exceeding global averages, making exports uncompetitive. Policies should encourage manufacturers to lower costs by increasing local production. By bringing suppliers into Vietnam and setting up local factories, they can reduce costs and become export-ready. Incentives should be provided to companies that successfully export,” suggested Dr. Thai.

Additionally, he noted that current tax policies on automotive components primarily focus on vehicle bodies, leading domestic companies to invest heavily in body stamping while core components like engines, transmissions, axles, and electronics are still imported as complete units. Common parts like tires and batteries are already well-produced domestically and require no further incentives.

“Globally, new engine types such as electric and hydrogen-powered engines are emerging. Encouraging investment in gasoline or diesel engine production is no longer aligned with future trends. Instead, policies should promote the development of future-proof components and systems, such as drivetrains, electronics, and steering systems,” he added.

“Empowering Auxiliary Industries: Focused Investments, Avoiding Over-Diversification.”

With regards to the strategic orientation of the supporting industries, representatives from the Ministry of Industry and Trade emphasized their focus on several key sectors for in-depth investment. These sectors include mechanical engineering, automobile, electrical-electronics and semiconductors, textiles-footwear and basic materials. By concentrating resources on these industries, they aim to avoid a scattered approach and foster a more concentrated and effective development.

Unlocking Electric Dreams: BYD’s First EV Factory in Southeast Asia

There is a possibility that BYD’s electric vehicle models, manufactured in Thailand, will soon be exported to Vietnam. This strategic move will enable the company to take advantage of import tax incentives and reduce the cost of their products.