Lightning-Fast Construction

Upon its completion by a consortium of Vietnamese enterprises, the National Exhibition Center not only impressed with its status as the largest in Southeast Asia and among the top 10 globally but also with its remarkable achievements. These include a “lightning-fast” construction time of just 10.5 months and the Kim Quy Dome, which set a world record with 24,000 tons of steel, millimeter-precision engineering, and a construction period of only 5 months.

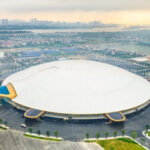

Spanning over 90 hectares, it stands as one of the world’s largest exhibition centers, poised to become an international hub for trade and cultural events. The main building comprises 9 sections with a total floor area exceeding 130,000 m², symbolizing the Kim Quy Turtle, a historical and cultural icon representing the resilience of the Vietnamese people.

Notably, Vingroup acted as the “central coordinator” of a massive machinery of Vietnamese companies like ATAD, QH Plus, and Dai Dung. These firms served as specialized “arms,” collaborating seamlessly to achieve this extraordinary feat.

Companies like QH Plus, ATAD, and Dai Dung are no strangers in Vietnam or even globally. QH Plus made waves by handling all steel structures for Landmark 81, Vietnam’s tallest tower, and contributed to the VinFast factory and various Vinhomes projects.

ATAD has completed over 4,000 steel structure projects in more than 60 countries, including 30,000 tons of steel for the VinFast Hai Phong project. Meanwhile, Dai Dung supplied steel structures for two stadiums during the 2022 World Cup in Qatar.

The 24,000-ton steel dome of the Kim Quy Exhibition Center captivates visitors.

To construct the world’s largest steel dome at the Kim Quy Exhibition Center, ATAD was tasked with 2 of the 9 halls, accounting for 20% of the total steel volume. ATAD immediately mobilized 8 factories to produce large-diameter steel pipes. With 112 days of construction, ATAD became the first steel structure unit to complete its work on April 25, 2025, setting the pace for the project’s rapid progress.

Reflecting on this journey, Mr. Do Duc Trung, Sales Director of ATAD Steel Structure Company, recalled receiving a call from Vingroup on September 2, 2024, about joining the Kim Quy steel dome project. He promptly mobilized all personnel for the construction plan. Typically, 24,000 tons of steel would take 1.5 to 2 years to complete. However, Vingroup required completion within 10 months.

“The entire project had a 10-month deadline. Specifically, the steel dome had to be completed in just 5 months, as foundation work had to be finished before installation could begin. The dome also needed to be ready by April 25, 2025, to allow for roof and other component installations. The timeline was incredibly tight,” Mr. Trung recalled.

Under strict requirements from the investor, supervisors were dispatched to each factory to monitor the quality of every component.

“Modules produced by one factory had to align perfectly with those from another. The large-diameter steel pipes, when connected, allowed for only millimeter-level errors, with no room for mistakes. It had to be ‘perfect on the first try,’ with no second chances,” Mr. Trung explained.

Working alongside ATAD were QH Plus and Dai Dung. QH Plus handled 3 halls, with a steel volume equivalent to ATAD’s.

Mr. Nguyen Hoang Huan, CEO of QH Plus Steel Structure Company, noted that despite managing nearly 20 domestic and international projects, the company prioritized this project by mobilizing 500 production personnel and 150 engineers on-site, designating it as their “top priority.”

Given the high-altitude construction, with the highest point reaching 56 meters, large cranes ranging from 350 to 500 tons were maximally utilized. Despite the year-end construction peak nationwide, long-standing supplier networks enabled contractors to gather nearly all northern resources at Co Loa.

At its peak, the National Exhibition Center project had 3,000 workers and engineers on-site, with hundreds of contractors and thousands of machines. Thanks to this, the project was completed on schedule within 10 months, compared to the global record of 36 months for similar-scale projects.

For Dai Dung, this was not the first time facing a tight deadline. In 2017, during the Qatar World Cup, the Lusail Stadium project faced issues with a Turkish contractor. Dai Dung was called in at the last minute, swiftly passing factory audits, production plans, and construction capability assessments. Mr. Trinh Tien Dung, Chairman and CEO of Dai Dung, noted they had only 5 months to complete the steel dome.

Mr. Dung highlighted that from the design phase, the steel dome was considered an “extremely challenging puzzle.” Its massive size, both in diameter and height, coupled with three architectural changes during construction, forced continuous adjustments to the structural plans.

With only 1.5 months left to finalize the solution, compared to nearly a year for similar projects, Dai Dung launched a full-scale plan with over 1,000 workers and engineers working in 3 shifts, 24/7. On-site, 500-ton heavy cranes operated continuously. Over 100,000 steel joints and high-strength bolts were precisely assembled under 3D laser scanning technology. Notably, all steel was produced in Vietnam.

During heavy rain, workers continued welding under soaked tarpaulins. Strong winds sometimes halted crane operations, but technical teams held emergency meetings on-site to adjust schedules.

“Hundreds of Dai Dung engineers worked day and night in design rooms, using advanced 3D software to simulate structures, continuously calculating load-bearing capacities, sagging, and resistance to wind, storms, and earthquakes. Everyone understood they were making history,” Mr. Dung recounted.

Vingroup – The Master Conductor

Achieving this lightning-fast construction and surpassing expectations required not only the efforts of Southeast Asia’s leading steel structure companies but also Vingroup’s role as a “master conductor.” Vingroup’s relentless, scientific, and meticulous leadership ensured the project’s completion in just 10 months, compared to the global record of 36 months for similar projects.

Vingroup, as the general commander, achieved a monumental feat.

Mr. Do Duc Trung praised Vingroup’s unique combination of decisiveness and attention to detail. Every design and construction plan was meticulously scheduled, with twice-daily reports to monitor progress. In case of rain or wind, plans were immediately adjusted on-site, ensuring not a single minute was wasted.

Mr. Nguyen Hoang Huan was impressed by Vingroup’s “one-touch” problem-solving approach: issues were resolved swiftly, efficiently, and effectively.

“This advantage is rare among investors or general contractors. The ‘Co Loa Miracle’ bears Vingroup’s significant imprint,” Mr. Huan concluded.

Mr. Huan also noted that being chosen by Vingroup for projects like the Vietnam Exhibition Center, Landmark 81, and VinFast factories was an opportunity for his company and Vietnamese enterprises to demonstrate their organizational, management, and technological capabilities.

“This allows us to confidently step onto the global stage, taking on more complex and demanding projects,” the CEO of QH Plus Steel Structure Company revealed.

At the Vietnam Private Sector Forum 2025 (VPSF 2025) on September 16, Prime Minister Pham Minh Chinh expressed deep admiration and emotion upon visiting the steel dome, designed, produced, and constructed by Vietnamese with unprecedented speed.

“A project like this, expected to take two years, was then reduced to one and a half years, and finally completed in 10 months, allowing us to enjoy it in recent days—truly lightning-fast,” the Prime Minister emphasized.

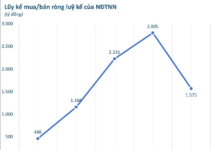

Unraveling the Surge: Decoding Vingroup’s Stock Market Heatwave

VIC shares are taking center stage in the stock market, having reached new highs four times in just two weeks, peaking at 153,200 VND per share. Following unfounded rumors about its financial health, the Group’s decisive legal action on September 8, 2025, not only restored confidence but also delivered a significant boost to the stock price.

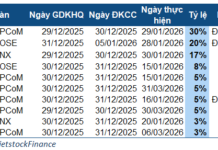

Vingroup Set to Reap 4.6 Trillion VND from 330% Dividend Payout by Partner Enterprise

According to the proposal presented to shareholders, the company plans to allocate nearly 5.5 trillion VND for this dividend payout.

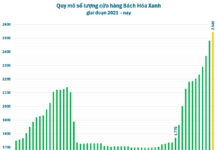

Vietnam’s Largest 2,870-Hectare Reclaimed Urban Project: Billionaire Pham Nhat Vuong’s Decade-Long Vision for a 108-Story Tower in Ho Chi Minh City Now Tops the Spotlight

After more than a decade of meticulous planning, the mega project Vinhomes Green Paradise in Can Gio is now entering a vibrant construction phase. The project’s progress has become a focal point of attention, reigniting the real estate market in Ho Chi Minh City.