On the morning of October 1st, the Specialized Session of Committee III on Industry, Manufacturing, Processing, and Production took place as part of the Vietnam Private Economic Panorama 2025 (ViPEL 2025). The session saw the participation of key members and Committee III members from ViPEL, alongside leaders of associations and prominent enterprises in the manufacturing and processing sectors.

Speaking at the session, Mr. Vu Van Tien, Chairman of Geleximco Group, highlighted Vietnam’s goal of achieving double-digit growth. According to Mr. Tien, this requires a strong focus on boosting exports, with small and medium-sized enterprises (SMEs) and millions of farmers, foresters, and fishermen as the driving forces.

Mr. Tien shared that over the past decade, the fisheries sector has surpassed the $10 billion mark, thanks to unity and a focus on producing what the market demands.

Regarding biotechnology, including agriculture, forestry, fisheries, and particularly biological products (antibiotics, medicines) that do not cause pollution, Mr. Tien emphasized the critical issue of wastewater treatment. He noted that paper mills are currently major polluters, not due to a lack of willingness to treat waste, but because of the absence of viable solutions.

Mr. Do Tri Tuan, Deputy General Director of Dai Dung Group, emphasized the importance of localization in manufacturing. While enterprises focus on exports, there is a need to localize “Made in Vietnam” products. Increasing the localization rate for inputs such as steel and other raw materials will reduce imports and foster the development of supporting industries.

Mr. Vu Van Tien expressed his surprise at Dai Dung’s achievements, noting their construction of a 24,000-ton steel dome and their involvement in a $700 million project in Saudi Arabia.

Mr. Tien stated, “We have the intelligence and ideas, but the question is how we act in challenging circumstances. Our ancestors succeeded in the past, and now, with greater advantages, we must not falter. Young people who fail to act are truly lagging behind.”

Pham Thi Ngoc Thuy, Director of the Office of the Board for Private Economic Development Research (Board IV), suggested that Committee III establish an alliance dedicated to increasing localization rates and developing supporting industries with Vietnamese value. She proposed setting clear goals for the next five years.

Echoing Ms. Thuy’s views, Tran Thi Thu Trang, Chairwoman and CEO of Hanel PT New Technology JSC, shared her perspective from the electronics and semiconductor industry. She believes Vietnam must focus on niche areas and tackle challenges that others avoid to achieve development.

In the machinery manufacturing sector, Ms. Trang urged Vietnamese enterprises to invest boldly in R&D and produce final products domestically rather than relying on imports. She emphasized the need to create reputable, globally recognized Vietnamese brands.

“If we continue to import and depend on foreign technology, we will forever remain followers,” Ms. Trang asserted.

She called on enterprises to form alliances to manufacture machinery for industrial and agricultural sectors. Currently, Vietnam’s agricultural exports remain 70-85% raw, with low processing rates compared to Thailand and China. Ms. Trang noted that increasing the processing rate of agricultural and aquatic products by just 10% could generate $5-7 billion annually. Post-harvest losses also amount to $3-4 billion yearly.

The ultimate goal, she stated, is to transform Vietnam into the “world’s kitchen,” producing high-value-added goods rather than raw exports.

Sharing this view, Dinh Duc Thang, Chairman of Stavian Chemical JSC, acknowledged the breadth of the processing and manufacturing industry. He supported the idea of forming an alliance to propose and implement national-scale projects.

Hoang Duc Vuong, Chairman of Vietcycle Corp, suggested that to develop supporting industries, foreign enterprises entering Vietnam should form joint ventures, enabling domestic firms to learn and grow.

Ngo Ngoc Khanh, Vice Chairman of the Vietnam Industrial Support Alliance (VISA), agreed on the need to increase localization rates. He emphasized that any alliance must include major foreign-invested enterprises (FIEs). Their participation and approval are essential for meaningful progress. He also called for specific policies, such as VAT incentives for Vietnamese firms supplying components to export processing zones.

Vingroup Invests $900 Million in Electric Vehicle Component Manufacturing Plant

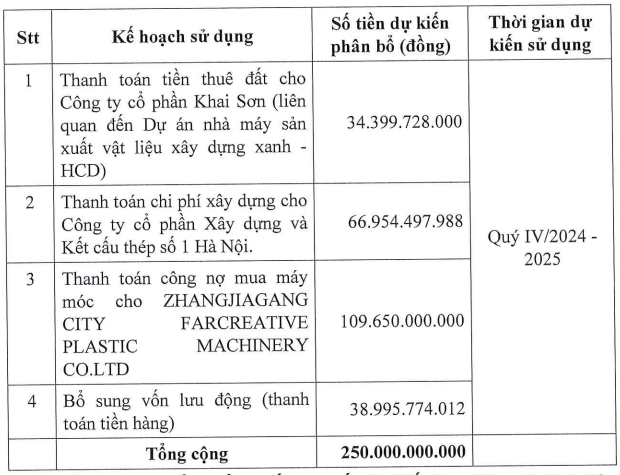

Vietnamese authorities have approved Vingroup’s $810 million (21.4 trillion VND) investment plan to develop an industrial complex dedicated to manufacturing materials, components, and parts for electric vehicles.

VinFast and the ‘Knockout Punch’ in the Self-Driving Electric Car Market: When Silicon Valley Nerds Meet the Hai Phong Fighter

Introducing a dynamic duo poised to revolutionize the autonomous driving landscape: the Silicon Valley tech upstart, Tensor, with its inventive prowess, and the formidable VinFast, armed with its state-of-the-art manufacturing muscle. Together, they’re not out to save the world, but to create a level 4 self-driving car that will transform the way we experience mobility.

The Great Manufacturing Reboot: China’s Surprising Strategy to Revive its Industries

“China continues to defy expectations, maintaining robust growth in labor-intensive industries despite a rising labor force. The country has leveraged a remarkable strategy to achieve this feat, one that has become an economic ‘miracle’.”