According to the International Renewable Energy Agency (IRENA) and the International Energy Agency’s Photovoltaic Power Systems Programme (IEA-PVPS), global solar panel waste is projected to reach 78 million tons by 2050, with recoverable material value up to $15 billion[1]. In Vietnam, under the ambitious solar energy development plan outlined in Power Development Plan VIII, PV waste is estimated to increase from 148 thousand tons in 2022 to 1.7 million tons by 2050[2].

The Ticking Time Bomb of PV Waste

The solar energy boom over the past two decades has driven a clean energy revolution but also signals a new environmental challenge. Solar panels have a lifespan of 25-30 years, meaning projects from the early 2000s will reach end-of-life in the coming decade. In 2022, Europe collected 48,395 tons of PV waste from 18 countries[3].

A standard solar panel consists of 67.5% glass, 12.7% aluminum, 2.7% silicon, 1.3% copper, and precious metals like silver[4]. Silicon production is energy-intensive with a high carbon footprint. The World Bank reports that demand for critical minerals in the clean energy transition could increase by nearly 500% by 2050, straining global supply chains[5].

The EU’s Critical Raw Materials Act sets targets: at least 25% of annual consumption from recycling, 10% from domestic extraction, and no more than 65% from a single third country[6]. Recycling and secondary material use reduce both resource extraction pressure and the carbon footprint of the solar value chain. UNEP emphasizes optimized raw material use and recycling as key to sustainable development goals[7].

Solar Panel Recycling: From Waste Management to Strategic Resource

Current PV recycling technologies include mechanical and chemical/thermal processes. Mechanical recycling, common in standard facilities, recovers low-value glass and aluminum. Chemical/thermal methods recover high-purity silicon, silver, and other valuable materials for manufacturing.

Fraunhofer Institute for Solar Energy Systems (ISE) produced new PERC cells from 100% recycled silicon, achieving 19.7% efficiency[8]. While lower than advanced PERC cells (22.2%)[9], this process uses Fluidized Bed Reactors (FBR), reducing energy consumption by 80-90% compared to traditional methods[10].

First Solar, a leading manufacturer, operates a closed-loop recycling system for CdTe thin-film panels, achieving 95% material recovery in 2023. With facilities in the US, Germany, Malaysia, Vietnam, and India, they process 88,000 tons annually, recycling 2.6 million panels per year. Since 2005, they’ve recycled nearly 400,000 tons of PV panels, more than any other program globally[11].

REC Silicon’s advanced FBR technology produces silicon with the lowest carbon footprint, using less energy and more efficient reactor space than traditional methods[12].

Economically, IRENA forecasts that recovered materials from global PV waste could exceed $15 billion by 2050[13]. Rystad Energy estimates the solar recycling market at $2.7 billion by 2030, growing to nearly $80 billion by 2050[14], positioning recycling as a promising industry optimizing the value chain and generating significant revenue from secondary materials.

Illustrative image.

|

Barriers to Unlocking the Goldmine in Old Panels

Despite potential, PV recycling faces challenges. High costs exceed material value at small scales. NREL reports recycling costs of $15-$45 per panel, with recovered value currently lower[15].

Technological limitations hinder high-purity separation of valuable materials like silver and silicon. Only a few entities, such as First Solar and Fraunhofer ISE, master these processes.

Logistics infrastructure for collection is lacking. Solar panels are often installed in remote, dispersed locations, requiring specialized systems. UNDP identifies this as a key barrier in Vietnam[16].

Vietnam lacks mandatory Extended Producer Responsibility (EPR) regulations for solar panels, unlike the EU. While the 2021-2030 National Environmental Protection Plan addresses solid waste, specific PV regulations are absent, creating a legal gap.

Secondary environmental risks are significant. Solar panels contain heavy metals like lead and cadmium, posing contamination risks if recycling is not strictly controlled. The US EPA classifies some panels as hazardous waste if they fail TCLP tests[17].

| TCLP (Toxicity Characteristic Leaching Procedure) is a US EPA test simulating landfill conditions to detect toxic leaching. If levels exceed thresholds, waste is classified as hazardous. |

A Roadmap for Vietnam

To turn PV waste into opportunity, Vietnam needs a comprehensive strategy. Developing a domestic recycling industry creates a strategic secondary supply of critical materials like silicon and silver, enhancing economic autonomy and energy security.

Integrating PV waste management into Power Development Plan VIII is essential. MOIT projects solar capacity reaching 46,459-73,416 MW by 2030, requiring immediate preparation for substantial waste[18].

Implementing EPR policies with clear timelines, including recycling fees, manufacturer funds, and lifecycle monitoring, as seen in Germany and France[19].

Developing high-tech recycling industrial zones, modeled after China and South Korea, integrates recycling with manufacturing for a closed-loop system. GGGI supports green investment in Vietnam, including waste management projects[20]. IFC committed $1.6 billion for Vietnam in FY2024, with $310 million for climate projects, offering FDI opportunities in PV recycling[21].

Public-private partnerships (PPPs) in collection, transport, and processing optimize resources. VCCI highlights recycling’s alignment with ESG goals, enhancing competitiveness.

[1] https://www.irena.org/publications/2016/Jun/End-of-life-management-Solar-Photovoltaic-Panels

[2] https://vjs.ac.vn/jst/article/view/19251

[3] https://iea-pvps.org/wp-content/uploads/2025/07/IEA-PVPS-T12-31-2025-EXECSUMM-Status-Module-Recycling.pdf

[4] https://publica.fraunhofer.de/bitstreams/71e72a21-4a1a-4516-a51a-3483603e77cb/download

[5] https://documents1.worldbank.org/curated/en/099052423172525564/pdf/P16627806f5aa400508f8c0bdcba0878a3e.pdf

[6] https://single-market-economy.ec.europa.eu/sectors/raw-materials/areas-specific-interest/critical-raw-materials/critical-raw-materials-act_en

[7] https://unece.org/sites/default/files/2024-06/S8_3__Global%20Material%20Flows%20Database_UNEP%20Ekaterina%20Poleshchuk.pdf

[8] https://publica.fraunhofer.de/bitstreams/71e72a21-4a1a-4516-a51a-3483603e77cb/download

[9] https://www.energieforschung.de/en/home/news/2022/world-recycling-day-recycled-silicon-for-new-solar-cells

[10] https://recsilicon.com/technology/

[11] https://www.businesswire.com/news/home/20240909937420/en/Responsible-Solar-First-Solar-Leads-Industry-with-Validated-Environmental-and-Social-Performance-and-Transparent-Reporting

[12] https://recsilicon.com/technology/

[13] https://iea-pvps.org/key-topics/irena-iea-pvps-end-of-life-solar-pv-panels-2016/

[14] https://www.rystadenergy.com/news/reduce-reuse-solar-pv-recycling-market-to-be-worth-2-7-billion-by-2030

[15] https://docs.nrel.gov/docs/fy21osti/74124.pdf

[16] https://files.acquia.undp.org/public/migration/vn/20211206_EoL-solutions-for-Solar-PV-and-Wind-Power-in-VN_final.pdf

[17] https://www.epa.gov/hw/end-life-solar-panels-regulations-and-management

[18] https://vietnamenergy.vn/approval-of-the-implementation-plan-for-the-adjustment-of-pdp-viii-34295.html

[19] https://iea-pvps.org/wp-content/uploads/2025/07/IEA-PVPS-T12-31-2025-EXECSUMM-Status-Module-Recycling.pdf

[20] https://thoibaotaichinhvietnam.vn/vietnam-gggi-continue-cooperating-in-green-growth-166458.html

[21] https://www.ifc.org/en/pressroom/2024/ifc-s-record-climate-financing-in-viet-nam-supports-green-transition-private-sector-resilience

– 12:00 01/11/2025

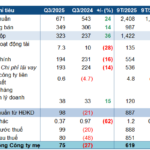

GEG Reports Q3 Profit of VND 75 Billion, Attributed to Electricity Price Lock-In; 9-Month Net Profit Surges 7x Year-on-Year

With the official electricity prices set for the Tan Phu Dong 1 (TPD1) wind power plant and the A7 turbine of the VPL Wind Power Plant, Gia Lai Electricity Joint Stock Company (HOSE: GEG) has reported a remarkable third-quarter performance compared to the same period last year, which saw losses. This positive shift has significantly brightened the company’s cumulative financial outlook.

T&T Group Plans $1 Billion Urban Development in Future Centrally-Administered City

T&T Group is spearheading the development of a visionary mixed-use urban complex, seamlessly blending commercial services with a world-class golf course in Vĩnh Lương, Bắc Nha Trang. Spanning approximately 830 hectares, this ambitious project is poised to redefine luxury living and leisure, with an estimated investment of 23 trillion VND.

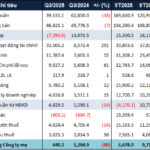

Vingroup’s Total Assets Surpass 1 Quadrillion VND Milestone

Vingroup (HOSE: VIC) reported a consolidated net revenue of VND 169.6 trillion for the first nine months of 2025, marking a 34% year-on-year growth and reflecting significant improvements across its core business segments. After accounting for expenses, the post-tax profit reached nearly VND 7.6 trillion, up 86%, achieving 76% of the annual target.