Saint-Gobain Vietnam Representative Engages in Discussion

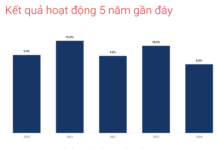

With 30% of its sales over the past five years stemming from new products and 75% of its portfolio comprising lightweight, low-carbon materials, Saint-Gobain Vietnam is committed to partnering with the government to achieve net-zero emissions by 2050.

Under the theme “Innovation for Sustainable Green Buildings and Green Transportation,” the event gathered over 1,000 delegates from government agencies, international organizations, industry experts, and businesses. This multi-dimensional forum aimed to identify challenges, unlock opportunities, and propose practical solutions for sustainable urbanization in Vietnam.

Saint-Gobain Vietnam participated with an exhibition booth and two strategic presentations during the plenary and breakout sessions, showcasing its strategic vision and concrete actions to fulfill its commitments.

Plenary Session: Transforming Urbanization into a Green Transition Catalyst

At the plenary session, Mr. Nguyen Truong Hai, CEO of Saint-Gobain Vietnam, delivered a keynote address titled “Transforming Urbanization into a Green Building Transition with a Lightweight, Low-Carbon Material Ecosystem.” As a pioneer in green building materials, Saint-Gobain Vietnam introduced its ecosystem of lightweight, high-performance, and low-carbon solutions. These innovations enable developers and contractors to optimize designs, accelerate project timelines, and proactively manage carbon emissions throughout a building’s lifecycle.

Mr. Nguyen Truong Hai, CEO of Saint-Gobain Vietnam

To maintain its leadership position, Saint-Gobain has identified research and development (R&D) as a strategic pillar for long-term growth. The group invests approximately $600 million annually in global R&D activities, focusing on innovative materials that reduce carbon emissions, conserve energy, and preserve natural resources. A testament to this commitment is the 2025 launch of DURAflex® Low Carbon, Vietnam’s first green cement board with a product lifecycle assessment (LCA) certified to international standards and an Environmental Product Declaration (EPD).

The DURAflex cement board manufacturing plant in Quang Tri has successfully incorporated biomass fuel into the production of DURAflex® Low Carbon green cement boards, reducing CO₂ emissions by 74% per m² of product. This achievement underscores Saint-Gobain Vietnam’s commitment to greening the building materials industry and progressing toward carbon-neutral manufacturing models in Vietnam and Southeast Asia.

At the forum, Saint-Gobain also proposed that the government consider mandatory carbon labeling for building materials. This would provide developers with a basis for making informed choices while addressing embodied carbon—a significant bottleneck that could hinder the industry’s and nation’s journey toward net-zero emissions.

Breakout Session: Solutions for Reducing CO₂ Emissions in the Construction Industry

Globally, the construction industry accounts for 36% of total energy consumption and 35-40% of CO₂ emissions (according to IEA). In the breakout session on “Sustainable Solutions for Reducing CO₂ Emissions in the Construction Industry,” Mr. Le Huu Sang, Global Operations Support Director for Fiber Cement at Saint-Gobain, emphasized that the operational phase of a building’s lifecycle is the most energy-intensive stage, where materials demonstrate their true value.

Mr. Nguyen Truong Hai, CEO of Saint-Gobain Vietnam, affirmed, “Saint-Gobain’s presence and commitment to sustainable development are closely aligned with Vietnam’s long-term growth strategy. We are confident in the government’s determination to achieve the 2050 Net Zero goal and stand ready to contribute through our ecosystem of lightweight, sustainable, and low-carbon building material solutions. Looking ahead, Saint-Gobain pledges to reduce Scope 1 and 2 CO₂ emissions by 33% by 2030 and achieve carbon neutrality across our entire operational footprint by 2050.”

LEGO and Pandora Projects Implement Saint-Gobain’s Fire Protection Solutions

Modern industrial parks like VSIP have emerged as prime investment hubs, attracting global giants such as LEGO and Pandora to operate billion-dollar facilities that adhere to stringent green, clean, and safety standards. Within these parks, advanced fire-resistant materials and solutions play a critical role, safeguarding not only human lives and assets but also ensuring uninterrupted production processes.

A Brighter Future: The BIM Group’s Sustainable Development Strategy

Established in 1994, BIM Group has consistently focused on knowledge-based and efficient investment strategies, solidifying its position as a leading conglomerate in Vietnam. With a diverse range of business interests, the Group has played a pivotal role in driving the country’s economic growth and development.

Maximizing Energy Efficiency in Buildings with Saint-Gobain Isover Glass Wool

Saint-Gobain Isover glass wool can contribute to eight major areas – accounting for a significant 60% of the total points available across the four most popular green building rating systems.

“Vietnam Could Reap Billions in Economic Benefits by Implementing ETC Tolling”

According to estimates by Professor Vu Minh Khuong, from 2019 to 2030, the implementation of electronic toll collection (ETC) on expressways will yield not only economic benefits of approximately 5.3 billion USD but also a potential reduction of 2.3 million tons of CO2 emissions. Additionally, it is expected to save 727 thousand tons of gasoline and diesel, over 1 billion workforce hours, 445 million vehicle lifespan hours, and 465 million USD in toll collection operation costs.

The Green Revolution: Vietnam’s Construction Industry and Its Sustainable Journey

The Vietnamese high-tech construction materials industry has undergone a remarkable transformation. Once heavily reliant on imports, the industry has now achieved self-sufficiency in domestic production and boasts a significant export capacity, accounting for 10-30% of total output. Notably, some factories dedicate up to 90% of their production to international markets, showcasing the sector’s impressive evolution and global reach.