Embarking on a Cloud ERP project to establish a modern digital operational model—where all decisions are based on real-time data—Phú Tài continues to boldly expand this model across its entire 7 units in the stone and wood industries. This is not merely a technological advancement but a clear testament to the fact that with the courage to begin and the perseverance in the digital transformation journey, technology can become a sustainable competitive advantage, enabling Vietnamese businesses to confidently enter the global race.

The manufacturing sector, particularly the production of quartz stone and wood—a specialized segment within the construction materials industry—operates on continuous automated lines, demanding near-absolute precision, stringent quality standards, and substantial investment costs. Therefore, digital transformation in this field is often considered a “tough challenge.”

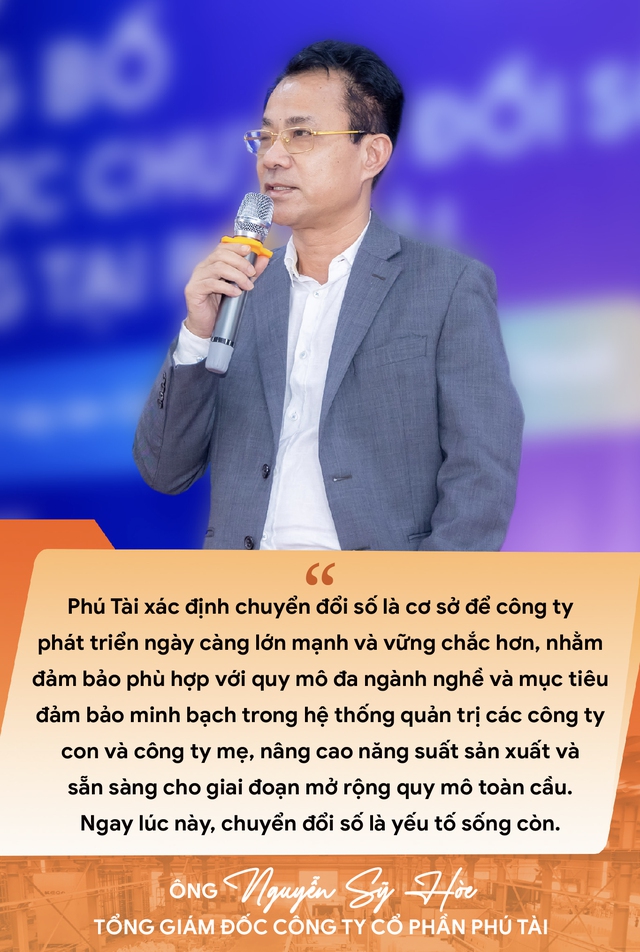

Mr. Nguyễn Sỹ Hòe, CEO of Phú Tài Joint Stock Company, shared that Phú Tài is a company with over 30 years of development across various industries, starting from wood, stone, compressed materials, forest investment, to mining systems providing raw materials for the stone industry, and other service sectors like real estate.

“Therefore, to meet the increasingly large and sustainable development scale, Phú Tài identifies digital transformation as the foundation for the company’s growth and breakthrough in the future, with development planned for 2026. Especially in meeting the operational requirements of a multi-industry scale and the goal of ensuring transparency in the governance system of subsidiaries and the parent company, enhancing production efficiency, and readiness for global expansion. Right now, digital transformation is a matter of survival,” Mr. Hòe emphasized.

Meanwhile, the manufacturing materials sector—particularly quartz stone—faces initial challenges in digital transformation: fragmented data, lack of standardization, and much of it remains outside the system. Many businesses operate in a “data blindness” state where machine productivity and loss rates in stages like crushing, mixing, pressing, and grinding are not fully recorded. Old equipment cannot connect or collect real-time data, causing quality control and cost optimization to still rely on manual experience—both slow and inconsistent.

The next challenge stems from the specific nature of quartz stone production: complex processes, many variables, and heavy reliance on craftsmanship. Input materials like powder, granules, and glue fluctuate continuously, but there lacks a deep enough data foundation to evaluate, forecast, and make decisions. This turns optimizing formulas, controlling costs, or ensuring quality into a “post-event evaluation” rather than proactive decision-making.

And finally—but most impactful—is the human and organizational factor. Many businesses lack teams that understand both technology and production techniques, while resistance to change makes digital transformation initiatives easily “bottlenecked.” Without consensus and a sufficiently prepared organizational structure, all technological efforts struggle to create real value.

In this context, Phú Tài faced a choice: to continue operating under a risky traditional model or embark on a bold journey to modernize its entire “operational DNA” through technology. The company chose to start by implementing it for a typical unit, Phutai Quartz Stone.

On February 7, 2025, Phutai Quartz Stone, together with FPT, initiated the implementation of SAP S/4HANA Cloud Public Edition. Just five months later, the system was officially put into operation—an impressive speed in the construction materials manufacturing industry.

In this project, the business set clear criteria: the partner must deeply understand the manufacturing industry—especially construction materials, have experience implementing ERP for large enterprises, possess a strong team of experts, commit to long-term collaboration, and ensure progress, quality, and security at the highest level.

With these requirements, SAP S/4HANA Cloud Public Edition became the optimal choice due to its global management standards, flexible scalability, automatic upgrades, and real-time management. FPT was trusted as a partner due to its leading ERP implementation capabilities over more than 20 years, industry understanding, comprehensive digital solution ecosystem, and team of experienced experts.

Accordingly, the project was implemented across critical subsystems such as financial accounting, sales, procurement, inventory management, production, quality management, and electronic invoice integration. The scope covered the entire process from finance, quartz raw material procurement, slab production, quality control, inventory management to sales and export.

This journey was guided by two clear strategic roadmaps. The first focused on building a management foundation, implementing standardized modules for all production and operational processes on SAP, helping the business transition from a fragmented operational model to an integrated system. The second aimed at optimizing operations, enhancing productivity, and controlling production and business plans in real-time, gradually forming a data-driven decision-making culture instead of relying on empirical intuition.

In parallel, FPT closely coordinated to design configurations and solutions suitable for Phutai Quartz Stone’s production and business realities, building separate process sets for each department from procurement, production, logistics to finance and business, ensuring the entire operational chain was standardized and seamlessly connected. Notably, FPT standardized raw material ratios and formulas like powder, granules, and glue, while tightly controlling even non-standardized materials—a challenging aspect in quartz stone production.

To ensure smooth changes, FPT conducted comprehensive training for each subsystem, built demo scenarios closely aligned with each unit’s operational realities, helping the internal team quickly grasp and effectively apply the system. Throughout the implementation and operation process, FPT maintained continuous support, promptly addressing and resolving any issues.

Mr. Võ Quốc Phương, Deputy Director of Production at FPT IS, FPT Corporation, and Project Director, assessed: “The success in implementing Cloud ERP for Phutai Quartz Stone lies in transforming data catalogs, forms, and business processes according to international standards. Along with this is linking all departments under a centralized management system, where data is inherited from one department to another, and advanced technology enables easy data retrieval.”

Sharing the project’s effectiveness, Mr. Đồng Văn Phước, Deputy Director in charge of Business at Phutai Quartz Stone, said: “After implementation, our working methods changed completely. From a manual operation model heavily reliant on Excel and disparate software, the entire process has been automated and standardized on a single system. All operations from procurement, production to sales now follow standard procedures, ensuring seamless and consistent data.”

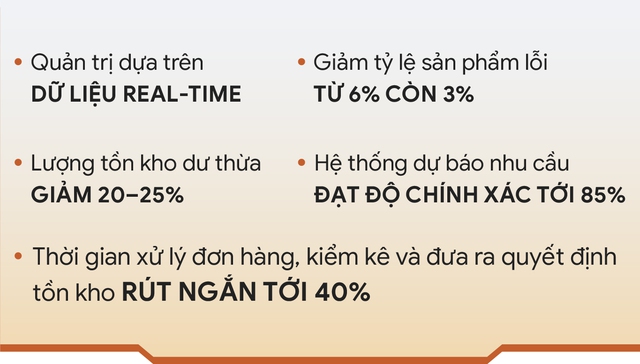

Previously, decisions were largely based on experience or intuition, but now all decisions are made based on real-time data. The leadership can instantly monitor production progress, inventory levels, or operational status in real-time, without waiting for consolidated reports from various departments.

More importantly, Phutai Quartz Stone shifted from operating under a fragmented process to a single standardized process for the entire company. From the office to the factory, all departments work on the same information stream; data is no longer fragmented, and there’s no more waiting for reports or manual reconciliation between departments.

In terms of operations, the new system helped standardize an end-to-end process from input, warehousing, production to business and finance. The value chain was fully connected, allowing tight control over each stage. Previously, quality was only assessed after the product was finished; now, the company can monitor every step in the production line, detect errors early, and adjust promptly. As a result, the defective product rate decreased from 6% to 3%.

Production scheduling capabilities also significantly improved, minimizing material disruptions and ensuring continuous line operation.

In terms of production efficiency, the system yielded clear results. Waiting times in production were reduced; loss rates in standards halved from 10% to 5%; inventory turnover improved; production costs were optimized; and the entire operational foundation became more flexible, enabling easier scale expansion.

Based on the clear results at Phutai Quartz Stone, on December 2, 2025, Phú Tài decided to partner with FPT to expand the digital transformation model across all 7 units in the stone and wood industries.

Among these, 5 stone units—Phú Tài Bình Định Quartz Stone Company Limited, Tuấn Đạt Mineral Company Limited, Workshop 380, Bình Định Decorative Stone Processing Factory, and Nhơn Hòa Construction Materials Production Workshop—will be simultaneously implemented within 4 months, inheriting the entire model, process set, forms, and operational methods optimized at Phutai Quartz. For the 2 wood units—Phú Tài Bình Định Wood Company Limited and Thắng Lợi Workshop—the system will be newly implemented, tailored to the wood production chain’s specifics but still adhering to unified corporate management principles.

Mr. Nguyễn Sỹ Hòe believes that success at Phutai Quartz Stone also offers a significant lesson about the essence of digital transformation. According to him, digital transformation in general and ERP in particular are true revolutions. Therefore, the most crucial factor is the absolute commitment of leadership, viewing ERP not as software but as the foundation for the company’s future.

When leaders adopt a “long-term investment” mindset and operational teams at all levels participate with proactiveness and determination, the transformation will occur faster, deeper, and yield greater value.

“Today, I believe that Phú Tài’s Cloud ERP implementation journey is the clearest testament to the three core values we pursue: creativity in thinking, speed in execution, and sustainability in development. And with this foundation, we confidently enter a new growth phase—more modern, synchronized, and ready to compete at a higher level in Vietnam’s stone and wood industries,” the CEO affirmed.

Mr. Đặng Trường Thạch, Executive Vice Chairman and Deputy CEO of FPT IS, FPT Corporation, noted that in digital transformation, all processes must operate on a digital foundation—like moving on a highway: to go fast, one must move with discipline and not stop arbitrarily.

Similarly, Cloud ERP needs to be built on standardized processes according to international practices and suitable for Vietnam’s realities.

“With over 20 years of experience implementing ERP for leading domestic enterprises, FPT commits to partnering with Phú Tài and SAP Vietnam to bring the project to successful completion, elevating management standards and turning technology into a new competitive advantage,” Mr. Thạch emphasized.

Currently, FPT has synthesized and introduced a new Cloud ERP implementation model called “The Next-gen ERP,” helping businesses easily access SAP’s internationally standardized management platform within just 3 months and at optimized costs. Phú Tài’s implementation model is a typical example demonstrating the determination and vision of a Vietnamese manufacturing enterprise in digital transformation and the capability of technology to accompany new approaches, delivering practical values.

“I believe the solution will meet three expectations in the digital transformation process in general and Cloud ERP implementation in particular. First is quick, on-time implementation and project success. Second is cost optimization, reducing implementation costs. Third is high management efficiency, meeting international standards,” Mr. Thạch added.

Phú Tài’s transformation journey not only marks a new step in the company’s management model but also becomes a practical lesson for thousands of Vietnamese manufacturing enterprises: to stand firm in the global business race, investing in technology and ERP Cloud is no longer optional—it’s a survival strategy.

Success from models like Phú Tài that dare to change to break through is expected to inspire businesses to proactively apply technology, contributing to the nation’s goals as outlined in Resolution 57-NQ/TW and enhancing competitiveness in the international market.

Record-Breaking Year: Vietnam Recovers Over 27.4 Trillion VND in Corruption Assets and Economic Gains

In 2025, Civil Judgment Enforcement Agencies nationwide surpassed the targets set by the National Assembly, notably achieving a remarkable recovery of over 27,400 billion VND in assets from corruption and economic crimes. This represents a significant increase of more than 5,230 billion VND compared to 2024.

International Card Organization Honors Sacombank for Digital Payment Development Excellence

Sacombank has been honored by the international card organization Mastercard with three consecutive prestigious awards, recognizing the bank’s relentless efforts and outstanding achievements in promoting cashless payments, optimizing its card portfolio, and supporting Ho Chi Minh City’s public transportation development strategy.

VietinBank Honored with Two Prestigious Awards for Transparency in Governance

During the 3rd to 5th of December 2025, in Ho Chi Minh City, VietinBank (Vietnam Joint Stock Commercial Bank for Industry and Trade – Stock Code: CTG) was honored with two prestigious awards. The bank secured a spot in the “Top 10 Companies with the Best Annual Reports in the Finance Sector” at the 2025 Listed Company Awards (VLCA). Additionally, VietinBank was recognized among the “Top 50 Pioneering Listed Companies Committed to Enhancing Corporate Governance in Vietnam – VNCG50” at the 8th Annual Corporate Governance Forum (AF8).