Statistics reveal a significant surge in the export turnover of wood and wood products, reaching $17.3 billion in 2025, solidifying Vietnam’s position as a leading exporter in this sector. During production, wood by-products such as wood chips, sawdust, and small branches are repurposed by companies to create wood pellets.

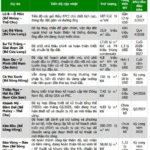

According to data from the Customs Agency, in the first 11 months of 2025, wood pellet exports reached $1.08 billion, a remarkable 52% increase compared to the same period in 2024. This product has seen the highest growth rate within Vietnam’s wood industry.

As of November 2025, wood pellet exports accounted for 7% of the total wood and wood product export turnover, up from 4.8% in the same period in 2024.

Notably, although full-year 2025 data is not yet available, Vietnam’s wood pellet exports have surpassed the $1 billion mark for the first time, marking a new milestone in the country’s export achievements.

Vietnamese wood pellets are highly favored in Japan and South Korea. Photo: Đỗ Hương/VPG |

Wood pellets are known for their cost-effectiveness and high energy output. They burn for an extended period, providing a consistent heat source with minimal ash. The combustion process produces less smoke and fewer harmful emissions compared to traditional fuels.

The growing demand for biomass energy in Japan, South Korea, and the EU has been a significant driver behind the surge in wood pellet exports in 2025.

In 2024, Vietnam exported 6.03 million tons of wood pellets, generating $805.27 million, representing a 29.1% increase in volume and an 18.5% rise in value compared to the previous year. South Korea and Japan were the primary importers, purchasing 94% of Vietnam’s total wood pellet exports.

A policy analyst from Forest Trends notes that despite contributing over $1 billion to the wood export turnover, the wood pellet industry faces several challenges. One major issue is the lack of dedicated raw material sources, making the industry reliant on secondary supplies from other wood processing sectors. This dependence makes production vulnerable to seasonality, waste prices, and supply instability, especially with increasing demand from Japan.

Additionally, stringent quality and sustainability requirements from export markets pose significant challenges. South Korea has recently tightened quality standards, driving up export prices, while Japan mandates FSC and PEFC certifications and is gradually introducing SBP certification for low-emission supply chains.

Given these challenges, experts advise companies to invest in developing their own raw material sources to reduce reliance on secondary supplies. They should also focus on ensuring product legality and sustainability to meet the requirements of export markets.

Tâm An

– 06:00 09/01/2026