Google Pixel Fold Smartphone

According to Nikkei Asia, citing sources close to the matter, Google will begin developing and manufacturing its premium smartphone lines—Pixel, Pixel Pro, and Pixel Fold—from scratch in Vietnam starting in 2026. This move parallels Apple’s strategy to shift iPhone production to India, reflecting a broader trend among U.S. tech giants to establish a closed supply chain outside China.

A Leap from Assembly to Product Inception

At the heart of Google’s new plan is the NPI (New Product Introduction) process, a critical and complex phase in electronics manufacturing. NPI encompasses design development, technical validation, and process optimization before mass production begins.

Historically, Vietnamese factories have primarily handled assembly from finalized designs. By taking on NPI, Vietnam will now play a direct role in the product’s conceptualization and development.

Illustrative Image

Industry experts view NPI as a “badge of honor” that validates a supplier’s technical capabilities. This phase requires hundreds of engineers from both Google and its partners to collaborate continuously, alongside significant investments in testing equipment and precision molds.

A source from Apple’s supply chain explains that NPI aims to ensure functionality, compatibility, and reliability for mass production. If NPI fails, the new product cannot launch.

Google remains cautious, however, as development of the lower-tier Pixel A series will continue in China. This separation indicates a calculated, long-term strategy based on the complexity of each product line.

Challenges in Ecosystem Building and China’s Dominance

While Google has already mass-produced smartphones and conducted some validation processes in Vietnam, fully relocating NPI from China is no small feat. Both Google and Apple maintain NPI operations in China due to its highly mature supply chain and decades of expertise.

Trade barriers pose another significant challenge. Nikkei Asia reports that Google’s efforts to expand production in Vietnam last year faced delays due to difficulties importing specialized manufacturing equipment. China is tightening export controls on machinery and restricting the movement of technical personnel to other countries.

A representative from a supplier working with both tech giants admits that much of the testing equipment is made in China and is difficult to export to third countries. This highlights the dependency on China’s auxiliary equipment ecosystem, which Vietnam and India will need time to overcome.

Prospects for an Independent Supply Chain

Lori Chang of Isaiah Research notes that early stages of supply chain diversification often involve replicating production or assembly processes. Only when local technical capabilities and component supplies mature do corporations move NPI overseas. Google’s decision signals that Vietnam’s supply chain has reached a certain level of technical readiness.

With potential tariff changes under the Trump administration looming since April, the urgency for U.S. companies to establish a “non-China supply chain” has intensified. If Google successfully develops smartphones from the ground up in Vietnam, it will demonstrate the new supply chain’s ability to operate independently, reduce reliance on a single market, and deepen Vietnamese businesses’ integration into the global value chain.

Vietnam: Asia’s Unrivaled Mastery Post-Singapore, Praised by EuroCham Chairman

Recently, Mr. Bruno Jaspert, Chairman of EuroCham, delivered a keynote address at the Swiss-Vietnamese Economic Forum 2025 (SVEF 2025), which opened in Da Nang. The event was jointly organized by the Da Nang People’s Committee, the Embassy of Switzerland in Vietnam, and the Swiss-Vietnamese Economic Forum (SVEF).

Apple’s Partner Doles Out Bonuses Totalling Over $2 Million to iPhone 17 Production Staff

On the eve of the iPhone 17’s highly anticipated launch, Foxconn is gearing up for its peak recruitment season, offering unprecedented bonuses to ensure a seamless production flow.

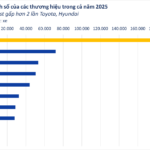

“Hyundai and Kia Need to Invest More in Vietnam to Reduce Dependence on China and Avoid US Tariffs”

Hyundai-Kia is looking to expand its production beyond China as a precautionary measure against potential new regulations that could be enacted by the government. Notably, the automotive giant is considering Vietnam as one of its alternative production hubs. This strategic move underscores the company’s forward-thinking approach to ensuring the continuity of its operations and mitigating potential risks associated with geopolitical factors. By diversifying its production bases, Hyundai-Kia reinforces its commitment to maintaining a robust global presence and adapting to the dynamic landscape of the automotive industry.