European automakers face a significant disadvantage in the electric vehicle revolution, according to Professor Ferdinand Dudenhöffer, a renowned German automotive expert.

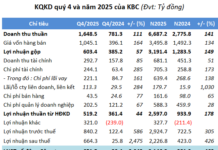

Car News China (CNC) reports that European car manufacturers are lagging behind in battery technology, a critical aspect of the electric vehicle (EV) market. Professor Dudenhöffer’s insights come as Chinese automakers celebrate record sales in Europe, surpassing 100,000 units in December 2025, capturing 9.5% of the market share.

“Europe is 20 years behind China in battery production,” Professor Dudenhöffer stated, highlighting the stark contrast in technological advancement.

European countries are struggling to keep up with the pace of battery production.

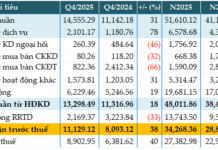

This technological gap has resulted in over 70% of EV batteries sold in Europe in 2025 being supplied by Chinese companies. To remain competitive, European manufacturers must consider collaborations with Chinese producers. China’s advantages include lower production costs, approximately 30% less than European counterparts, and a 50% shorter development cycle. While European companies take four years to design and produce a new battery, Chinese firms accomplish this in just two years at a significantly lower cost.

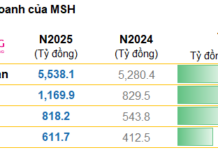

European battery manufacturers are facing challenges. Northvolt, a Swedish company, is at risk of bankruptcy due to technical issues and delivery delays, while ACC, a French firm, has halted its expansion plans. In contrast, Chinese giants like CATL and Gotion High-Tech are not only supplying components but also establishing production facilities in Europe.

CATL’s joint venture with BMW has commenced production in Germany, and BYD’s partnership with Stellantis is now mass-producing affordable lithium iron phosphate batteries.

The technological gap extends beyond batteries. Professor Dudenhöffer notes that Chinese companies in autonomous driving and smart cockpit technologies, such as QCraft, Horizon Robotics, Xiaomi, and Huawei, are leading the way, outpacing European and American competitors.

China dominates global battery production, controlling 75% of the market, particularly in lithium iron phosphate technology.

Despite Europe’s efforts to strengthen its domestic supply chain, battery production costs remain 50% higher than in China. The region relies heavily on imports for essential materials like lithium and nickel, with 80% sourced from abroad.

“If European automakers continue to rely on inefficient supply chains, they risk missing the opportunity to transition successfully,” Professor Dudenhöffer warned. He suggests that ongoing partnerships between Chinese and European companies could transform Europe from a “battery consumer” into a “Sino-German technology testing ground.”

China Poised to Become the World’s Largest Auto Exporter in the Next Five Years

According to Carscoops, Chinese automakers are ramping up exports of millions of affordable gasoline vehicles to the global market. This surge comes as domestic demand for gasoline cars in China experiences a significant decline.