The global shift towards electric vehicles and alternative energy sources is well underway, with governments and automakers alike seeking a balance between reducing emissions, combating climate change, and meeting personal transportation needs.

According to the World Economic Forum, the number of cars on the road is expected to reach 2 billion by 2050, putting immense pressure on climate goals if the majority still rely on fossil fuels.

However, the popularization of electric vehicles is not enough to achieve emission reduction targets in the transportation sector, as the electric vehicle supply chain is not truly sustainable. According to a study published in the scientific journal IOP Science, manufacturing an electric car produces an average of over 10 tons of carbon emissions, nearly double that of a gasoline car.

In other words, while electric vehicles are expected to be a key solution in achieving net-zero emissions, their supply chain is not truly green and could potentially place further strain on the environment.

HITTING TWO TARGETS WITH ONE ARROW

In reality, many electric vehicle manufacturing processes can be optimized to reduce resource and energy wastage, thereby lowering production costs and carbon emissions.

“Bühler owns many advanced technologies that have been introduced to Vietnam in recent years. Specifically, high-pressure aluminum casting technology is crucial in making vehicles lighter, stronger, and more environmentally friendly by reducing carbon emissions.”

Mr. Thomas Gass, Ambassador of Switzerland to Vietnam.

For instance, with traditional technology, an electric car body requires 70-100 separate parts to be assembled. Casting so many small parts can increase the risk of errors, not to mention the energy and resources consumed in cutting and assembling them.

Bühler’s high-pressure die-casting technology can address this issue. According to Mr. Rafael Diem, Director of Bühler’s Advanced Materials business in Southeast Asia, Bühler’s solution enables original equipment manufacturers (OEMs) to cast monolithic structures for electric vehicle bodies, significantly saving energy and resources.

Particularly, this technology can help OEMs produce electric vehicle components using aluminum, which is much lighter than steel, thus reducing the load during transportation.

Excess aluminum from trimming the finished casting will be melted and reused in the same factory, instead of being sent back to metallurgical companies, also reducing the carbon footprint of electric vehicle production.

Bühler’s technology helps reduce carbon emissions by about 0.2 tons for each vehicle part produced. Multiplied by tens of millions of cars manufactured each year, we can achieve a massive reduction in emissions.

Mr. Rafael Diem, Director of Bühler’s Advanced Materials business in Southeast Asia.

“Bühler’s technology helps reduce carbon emissions by about 0.2 tons for each vehicle part. Scaling that up to the tens of millions of cars produced annually, we can achieve a massive reduction in emissions,” said Mr. Rafael Diem.

In addition to the body, Bühler’s high-pressure die-casting technology is also used to produce battery casings with a lifespan of up to 20 years, ensuring safety and performance for electric vehicles.

Another solution offered by Bühler is optical coating technology, which creates chrome layers that are only 10% as thick as traditional chrome plating, saving 90% of resources while still providing wear resistance and enhancing durability for electric vehicle components.

Bühler’s solutions significantly reduce the production costs of electric vehicle components, providing a strong incentive for OEMs to adopt these new technologies.

“This is one of the main drivers for OEMs to apply Bühler’s new technologies,” affirmed Mr. Rafael Diem.

ALIGNING WITH SUSTAINABILITY GOALS

“Bühler aims to reduce by 60% the carbon emissions generated by its operations by 2050, including emissions per unit of equipment produced. More importantly, our solutions help reduce emissions, water consumption, and energy use by up to 50% compared to existing technologies,” emphasized Mr. Rafael Diem.

To achieve this goal, Bühler reinvests 5% of its annual net revenue into research and development (R&D), focusing on improving existing solutions, designs, and processes, and developing more advanced, automated, and digitized equipment that promotes sustainability and innovation.

Bühler’s solutions are expected to positively contribute to net-zero emission goals by promoting automation, supporting small and medium-sized enterprises, and driving the adoption of advanced materials.

Mr. Asif Abbas, CEO of Bühler Vietnam.

In parallel, Bühler’s team of technology experts and highly skilled engineers, including design engineers, automation engineers, and project management engineers trained to European standards, supports customers from the initial idea and design stages through to production, installation, and operational testing of equipment and technology applications, ensuring the final product meets agreed specifications and avoiding errors and waste in the manufacturing process.

Bühler’s advanced materials solutions are already present in the factory of Vietnam’s only electric vehicle manufacturer, as well as in many foreign-invested enterprises in Vietnam operating in this industry.

According to Mr. Asif Abbas, CEO of Bühler Vietnam, this strategy leverages Bühler’s strengths in actively promoting the development of Vietnam’s and the world’s electric vehicle industry.

Mr. Asif commended Vietnam’s efforts towards sustainability and its net-zero emission target by 2050. He believes that Bühler’s solutions will positively contribute to these goals by promoting automation, supporting small and medium-sized enterprises, and driving the adoption of advanced materials.

Buhler Asia Vietnam Co., Ltd.

Website: www.buhlergroup.com

Phone: 0981 131 727.

The Electric Revolution: Vietnam’s Chance to Lead or Fall Behind in the New Era.

The CEO of Dat Bike shed light on two pivotal trends: the shift from gasoline to electric vehicles and the move to diversify manufacturing away from China. These trends, when intersecting, present a unique opportunity to forge a new industry.

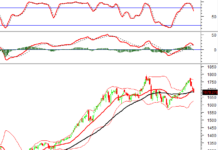

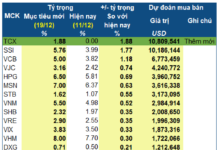

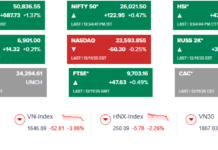

“VinFast Secures Backing from Vingroup and Chairman Pham Nhat Vuong to Fortify its War Chest and Accelerate its Ascent.”

On November 12, 2024, Vingroup and Mr. Pham Nhat Vuong announced a financial support package for VinFast. As part of this, Vingroup plans to provide VinFast with new loans of up to VND 35,000 billion by the end of 2026. In addition, Mr. Pham Nhat Vuong has committed to personally sponsoring VinFast with VND 50,000 billion. Furthermore, Vingroup will invest in VinFast Vietnam by converting the existing loan of approximately VND 80,000 billion into preferred shares, which will be eligible for dividends.