The food and beverage (F&B) market in Vietnam is experiencing rapid growth, and with it, the demand for safe, creative, and environmentally-friendly packaging is becoming increasingly crucial.

To keep up with this trend, Tetra Pak has expanded its aseptic packaging production in Binh Duong, enabling F&B businesses to access internationally-renowned packaging solutions locally.

In a recent interview, Mr. Adolfo Orive, President and CEO of Tetra Pak, shared insights into how this investment will drive innovation and sustainability, supporting F&B brands in gaining a competitive edge in a rapidly evolving market.

Could you share Tetra Pak’s recent achievements in Vietnam and its development strategy for the Southeast Asian region?

Six years ago (in 2019), we inaugurated our first production line at the Binh Duong factory. We recognized Vietnam’s immense growth potential, driven by a strong focus on innovation and high-quality food products from consumers.

The Binh Duong factory boasts modern and advanced technology, setting it apart in the region.

Within just six years, the Binh Duong factory has become one of Tetra Pak’s leading global facilities, excelling in quality and operational efficiency, and our team’s dedication to ensuring food safety is unparalleled. Thus, we felt it was the right time to expand our capacity to not only serve the domestic market but also meet the growing needs of the entire Southeast Asian region, which demands modern factories and advanced technology.

Our upcoming projects will diversify into new product groups, including ready-to-drink coffee, cold tea, pretzels, plant-based beverages, and nutritional food products. These are all areas with significant potential in Vietnam, where consumers are increasingly demanding creative, safe, and high-quality products that support agricultural development through reduced food waste and extended shelf life.

To meet these demands, our talented team of over 350 individuals at the Binh Duong factory plays a pivotal role in driving innovation and ensuring the highest quality standards throughout the product development process. Our factory operates with cutting-edge technology from Sweden, combined with the expertise of our local talent pool, making it a modern packaging hub that exemplifies technical excellence and quality.

In the region, we are implementing advanced packaging technologies, including one of the world’s fastest packaging lines, capable of producing up to 40,000 packages per hour, setting new benchmarks for efficiency and scalability in the F&B industry.

What achievements in the Vietnamese market make you feel the most proud?

Our success in Vietnam is attributed to two key factors.

Firstly, our unwavering commitment to ensuring food safety for consumers has always been our top priority. During the COVID-19 pandemic, Tetra Pak’s factory in Vietnam maintained uninterrupted operations, and many employees even volunteered to live on-site in makeshift camps to ensure uninterrupted food packaging supply.

Additionally, maintaining stringent quality standards underscores our long-term commitment to food safety. Amid challenges in the global supply chain, local and regional production expansion becomes especially crucial. Our production in Vietnam now plays a pivotal role in ensuring an efficient supply chain for both domestic and neighboring markets.

The expansion of the Tetra Pak Binh Duong factory increases its capacity to over 30 billion packages per year. This affirms our position as a key manufacturer in the Asia-Pacific region and enables us to maintain the highest quality standards.

Looking to the future, what gives Tetra Pak the confidence to continue expanding in Vietnam?

Vietnam’s young population, high internet usage, and vibrant coffee culture contribute to a dynamic and innovative market. Today’s consumers also prioritize nutrition and quality, which aligns with our strengths and areas of focus. Moreover, Vietnam’s agricultural development orientation fits perfectly with our vision of providing food safely and sustainably.

The Binh Duong factory is considered one of the most modern in the region. Can you elaborate on the R&D activities and technology applications at this site?

Over the years, Tetra Pak has invested approximately 500 million Euros in research and development (R&D) activities, demonstrating our strong commitment to innovation, sustainability, and adaptability to the ever-changing needs of the global F&B industry.

The advancements in knowledge and technology from our R&D efforts are swiftly applied to the Vietnamese and regional markets through practical solutions that cater to the diverse needs of consumers.

As a pioneer in the packaging industry, what are your thoughts on the trends that will shape the packaging sector in the next 3-5 years?

Regardless of how the industry evolves, food safety will always be the core focus of the packaging sector and the deciding factor in the effectiveness of any packaging solution. Additionally, packaging should provide convenience to consumers and drive sustainability through environmentally-friendly approaches.

Future packaging trends are likely to revolve around food safety, technological innovation, optimizing user experience, adopting bio-based materials, digitizing processes, and promoting sustainable development models. Currently, 70% of our packages are produced using renewable materials, significantly reducing CO₂ emissions.

What excites me about the future is the opportunity to lead a comprehensive transformation of the global food system. I believe Tetra Pak has all the advantages to make a real difference – not just for our customers but for society as a whole. We have the scale, the expertise, and, most importantly, the passion to create a positive impact.

“The General Secretary: The Vietnam Innovation Network in South Korea will be a bridge to bring the world’s best and brightest to Vietnam.”

“On the afternoon of August 10th, in Seoul, General Secretary To Lam met with members of the Vietnamese Innovation Network and Vietnamese experts and entrepreneurs based in South Korea. The gathering fostered a productive exchange of ideas and insights, with a shared focus on innovation and the potential for collaborative endeavors between the two nations.”

“Meeting with the Vietnamese Innovation Network in South Korea: A Conversation with General Secretary To Lam.”

“As part of his state visit to South Korea, on August 10, Party General Secretary To Lam and the high-ranking Vietnamese delegation met with members of the Vietnamese Innovation Network and Vietnamese experts in Seoul. “

“Vinmec and Ho Chi Minh City National University Join Forces to Enhance Healthcare Quality”

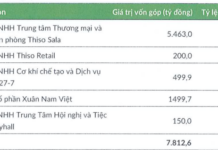

Vinmec Healthcare System and Ho Chi Minh City National University (HCM NIU) have forged a strategic partnership to enhance the nation’s healthcare standards and develop high-quality medical personnel. This collaboration aims to synergize the expertise of both institutions, elevating the level of healthcare services and fostering professional excellence within the medical community in Vietnam.

Green Transformation: Empowering Businesses to Meet Market Demands, Secure Orders, and Boost Exports

The green transition is not only an inevitable trend in modern economic development, but it also brings numerous tangible benefits. By reducing greenhouse gas emissions and protecting the environment, we can create a sustainable future with countless advantages.