The rapid growth of Vietnam’s aviation industry amidst globalization

Amidst the robust wave of globalization and international integration, Vietnam’s aviation industry has witnessed remarkable growth in recent years. The demand for aircraft components in the aviation sector is soaring to new heights.

Currently, aircraft component manufacturing is dominated by foreign-invested enterprises, featuring industry giants. For instance, Hanwha Group (South Korea) established Hanwha Aero Engines Co., Ltd. in Hoa Lac Hi-Tech Park—Vietnam’s first aircraft engine manufacturing plant. With an initial investment of over $200 million (planned to expand to $260 million), the factory commenced operations in two phases, generating $140 million in revenue (over VND 3.4 trillion) in 2023.

Additionally, Meggitt Group (Paris) founded Meggitt Vietnam Co., Ltd. (Artus Vietnam Co., Ltd.), specializing in manufacturing transformers, aviation control equipment, and repairing aviation components, with an initial registered capital of $17 million. In 2007, Mitsubishi, through its subsidiary MHI Aerospace Vietnam, invested $7 million in a 19-hectare facility in Thang Long Industrial Park for aircraft wing repair, manufacturing, and processing.

UAC Group (USA) invested $170 million in an aircraft component manufacturing plant in Da Nang through its subsidiary. The project, spanning 170 hectares, began Phase 1 operations in March 2020, producing nearly 12,500 tons of components annually for global leaders like Boeing and Airbus.

Notably, AESC (Aircraft Engineering Services Company) stands as Vietnam’s sole domestic enterprise in aircraft component manufacturing. Established in 2008 with a 10-person team led by Tran Hai Dang, AESC specializes in manufacturing and repairing aircraft parts and airport equipment.

AESC is Vietnam’s first private aviation company certified by global authorities—FAA, EASA, and the Civil Aviation Authority of Vietnam—as a Part 145 Maintenance Organization and Part 21 Manufacturing Organization.

In early 2016, the Civil Aviation Authority of Vietnam recommended AESC to the Ministry of Transport for collaboration with Airbus in developing Vietnam’s aviation support industry. Director Lai Xuan Thanh praised AESC’s capabilities, emphasizing its potential as an Airbus partner to advance Vietnam’s aviation sector.

In May 2024, AESC increased its charter capital from VND 150 billion to VND 200 billion. The company is chaired by Hoang Anh Chien, with Tran Hai Dang as CEO.

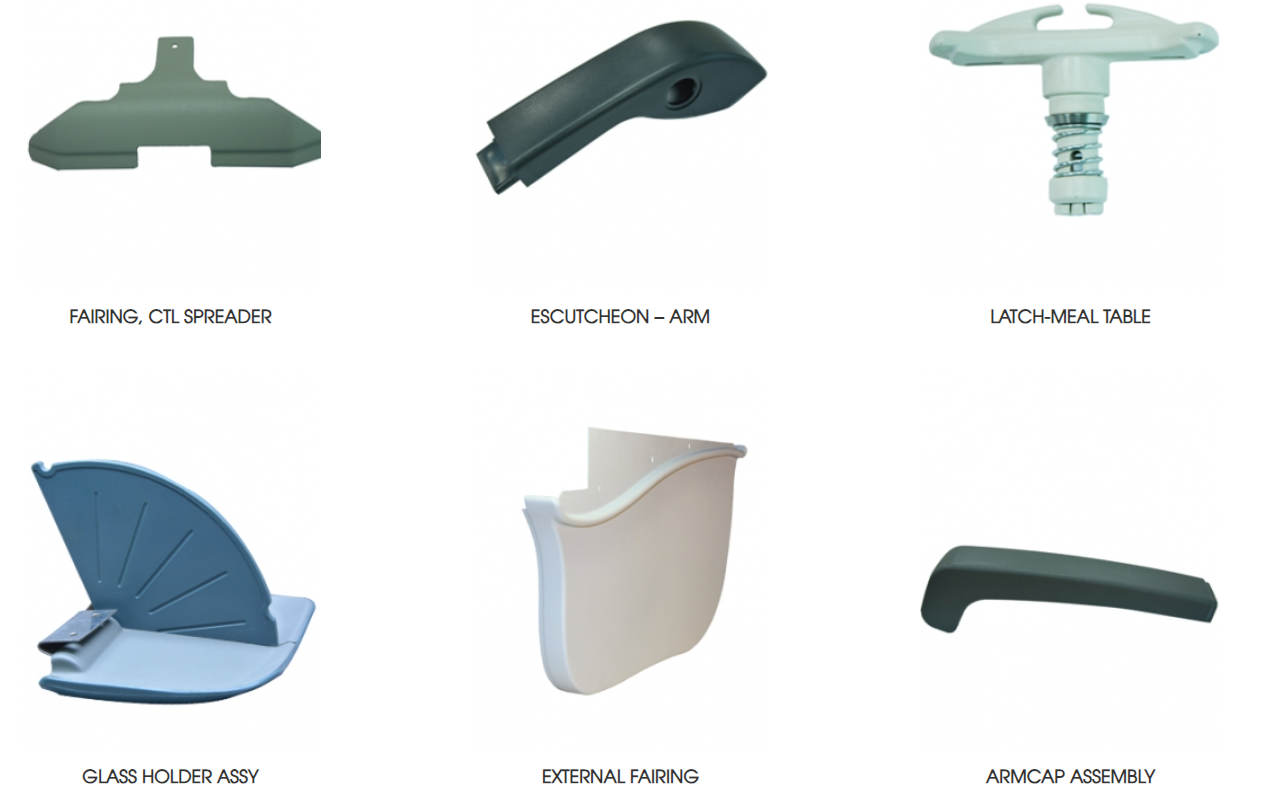

As Vietnam’s sole EASA Part 21G-certified manufacturer, AESC produces aircraft interior components for replacements and repairs. In August 2010, it became Vietnam’s first company authorized to design and manufacture simple aircraft interior parts, localizing aviation products.

AESC’s interior products have been supplied to Vietnam Airlines, VietJet, Jetstar Pacific, and Lao Airlines for years.

AESC’s aircraft interior products

For ground support equipment, AESC designs, manufactures, maintains, and repairs various equipment, including GPUs, ASUs, ACUs, tractors, stair trucks, water trucks, lavatory trucks, and conveyor vehicles.

AESC’s ground support equipment

In aircraft maintenance and overhaul, AESC services brakes, wheels, seats, emergency equipment, galley components, life jackets, and evacuation slides/rafts.

AESC supplies over 15,000 aircraft parts, readily available in its inventory.

In training, AESC is a key investor in the New Zealand Aviation School joint venture—Vietnam’s first pilot training school, based at Chu Lai Airport.

SAGround Managing Director First Reveals the Stop of Providing Ground Service for Bamboo Airways

At the annual shareholders’ meeting on April 25, Mr. Dang Tuan Tu, Chairman of the Board of Directors of Saigon Ground Services Joint Stock Company (SAGS – stock code SGN), revealed that the company will stop providing ground services to Bamboo Airways.