At the first Vietnam Private Economic Sector Panorama High-Level Meeting (ViPEL 2025) held recently, Mr. Vu Van Tien, Chairman of Geleximco Group, made a notable statement about Vietnam’s manufacturing industry.

“For decades, our manufacturing industry has received significant government support, yet it hasn’t achieved a breakthrough. The localization rate for automobiles is only 5–20%, and for machinery and equipment, it’s 25–30%. Most of the added value still lies overseas,” he remarked.

Mr. Vu Van Tien, Chairman of Geleximco.

Historically, Vietnam has faced challenges in developing its automotive and related industries.

Economist Pham Chi Lan, former member of the Prime Minister’s Economic Advisory Council, noted in an interview that Vietnam has made considerable efforts to develop its industries and increase localization rates, particularly in automotive production.

She explained that Vietnam offers incentives to foreign car manufacturers if they commit to achieving a 30% localization rate within 10 to 15 years of operation.

Economist Pham Chi Lan.

At one point, Vietnam became a hub for major global car manufacturers, who established assembly plants, raising hopes for the country’s automotive industry.

“Back then, we all believed that these investments would boost the supporting industries, increase localization rates, and enhance Vietnamese workers’ skills and management capabilities. We hoped for technology transfers to establish a robust domestic automotive industry,” recalled Mrs. Pham Chi Lan.

However, most localization commitments have not been met.

This highlights the historical challenges in developing Vietnam’s automotive sector. Yet, recent years have seen significant changes.

What Can Vietnam Contribute to a Car?

In recent years, Vietnam’s automotive industry has made notable strides, as evidenced by the increased localization rates of domestically produced vehicles.

Previously, low localization rates were a persistent weakness, driving up production costs and reliance on imported components. Now, domestic manufacturers are addressing this through large-scale investment strategies aimed at developing local supply chains.

VinFast, Vietnam’s only automotive brand handling design, production, and commercialization, boasts a localization rate exceeding 60%, according to the Ministry of Industry and Trade and other sources.

The company aims to raise this figure to 84% by next year (2026) by expanding its supporting industrial complex in Hai Phong and partnering with hundreds of domestic and international suppliers. Additionally, VinFast’s in-house production of batteries, chassis, body panels, and electronic components is bringing it closer to full domestic manufacturing.

Inside VinFast’s Ha Tinh factory, specializing in compact car production.

Toyota Vietnam, a long-established player, maintains a localization rate of 33–37%, depending on the model. The Innova (around 37%) and Vios (around 34%) are the most localized models, assembled at the Toyota Phuc Yen plant in Vinh Phuc.

Toyota is expanding partnerships with domestic suppliers to develop components like plastic parts, wiring, seats, wheels, and lighting systems, which can be produced locally with consistent quality.

Toyota’s Vinh Phuc plant produced its 1 millionth vehicle earlier this July.

THACO Auto (part of THACO Group), which manufactures and assembles brands like Kia, Mazda, and Peugeot, maintains a localization rate above 40% for some models, particularly Kia passenger vehicles.

The THACO Chu Lai complex in Quang Nam is Vietnam’s largest automotive production and export hub, with factories producing components such as body panels, plastic parts, seats, wiring, and chassis. Many of THACO’s components are exported to markets like South Korea and India, showcasing the growing capabilities of domestic production.

Workers install engines and axles on a KIA Seltos at THACO’s plant.

Beyond these three brands, numerous other companies are contributing to Vietnam’s emergence as a regional automotive manufacturing hub.

Notable names include TC Group (assembling Hyundai and Skoda vehicles), Kim Long Motor (partnering with Changan to build a plant in Hue), and TMT Motors (assembling Wuling vehicles), all of which are bolstering Vietnam’s automotive industry.

Geleximco, chaired by Mr. Vu Van Tien, is also contributing to this growth. The company has partnered with Chery, China’s largest vehicle exporter, to build a plant in Hung Yen (formerly Thai Binh), expected to open next year. At full capacity, the plant will produce 200,000 vehicles annually, serving both domestic and regional export markets.

Geleximco is the distributor for Omoda & Jaecoo, Chery’s sub-brands.

While Vietnamese manufacturers still lag behind Thailand and Indonesia’s 40–60% average localization rates, the country’s automotive landscape is visibly transforming. Vietnamese plants are moving beyond assembly to establish integrated production chains, a critical step toward becoming a true domestic automotive producer.

The Nuts and Bolts of Vietnam’s Automotive Industry

To increase meaningful localization, Vietnam needs not only assemblers and manufacturers but also robust foundational industries, particularly materials and metallurgy, which are essential for mechanical production.

In this context, the entry of major conglomerates into basic materials production is a strategic move, enabling greater self-sufficiency and reducing reliance on imported components and high-quality steel.

A prime example is Vingroup’s establishment of VinMetal, a new venture in the heavy industry sector.

VinMetal will produce automotive steel for VinFast.

Recently, Vingroup announced the formation of VinMetal, marking its entry into the metallurgy industry, a cornerstone of Vietnam’s heavy industry.

With an investment of 10 trillion VND, VinMetal is located in the Vung Ang Economic Zone, Ha Tinh, and will have an initial capacity of 5 million tons annually. The company will produce advanced industrial steel, including hot-rolled steel, high-strength steel, and specialty alloys, for use in electric vehicles, high-speed infrastructure, and civil construction.

High-quality steel sheets and stamped car body panels will be flagship products, aimed at replacing imports and eventually targeting regional exports.

Steel sheets for car bodies after stamping in a VinFast factory.

Vingroup’s foray into metallurgy not only expands its “Industry – Technology” pillar but also completes Vietnam’s automotive value chain, from raw materials (steel) to components, body panels, chassis, and finished vehicles. This underscores the maturity of Vietnam’s domestic industry, as companies move beyond assembly to master core technologies and materials.

This development signals a new phase for Vietnam’s automotive industry, where critical components—steel, parts, batteries, and chassis—are increasingly produced domestically.

The notion that “Vietnam can’t even make bolts and nuts” is becoming outdated, as the country’s supporting industries rapidly expand in depth and scope.

Top 100 Most Powerful Women in Asia: VinFast Chairwoman, Vinamilk CEO, Viettel Global Leader, and ‘Sugar Queen’ Make the List

Fortune Magazine (U.S.) has unveiled its 2025 list of “Asia’s 100 Most Powerful Women,” featuring four prominent Vietnamese female leaders. These trailblazers hold key positions within major corporations, significantly impacting Vietnam’s economy while steadily establishing their presence on the global stage.

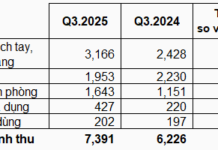

VinFast Achieves Milestone: Sells 100,000 Vehicles in Just Three Quarters, Setting a New Record in Vietnam

VinFast has officially become Vietnam’s first automotive brand to surpass 100,000 vehicle sales in just the first three quarters of the year, while also maintaining its position as the country’s best-selling car brand for 11 consecutive months.

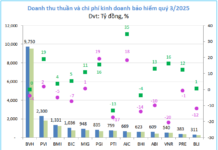

Vietnam’s Automotive Market Shows Promising Growth

With effective stimulus measures such as price reductions and design refreshes, domestic car sales have rebounded from their previous low point.