Once a leading trader with 65% market share in film-faced plywood

Founded in 2005, TEKCOM supplies plywood products for construction formwork, interior design, and ready-to-assemble (RTA) kitchen cabinets. Mr. Vu Quang Huy, Chairman and CEO of TEKCOM, shared that the decision to enter the plywood business stemmed from a request by a construction contractor client. The client brought a sample of formwork plywood and asked if the company could source it.

Despite limited resources, TEKCOM imported the entire batch, but the client rejected it due to quality issues. After engaging with multiple contractors, TEKCOM identified a shift from steel formwork to film-faced plywood, recognizing it as a “blue ocean” opportunity. After selling the initial batch, the company focused its resources on developing film-faced plywood.

From 2005 to 2011, TEKCOM operated as a trading company. After a period of exploration, the company experienced rapid growth from 2009 to 2011, capturing approximately 65% of Vietnam’s film-faced plywood market. In 2012, TEKCOM made a pivotal shift to manufacturing to gain control over product quality.

TEKCOM’s co-founders: Mr. Vu Quang Huy – Chairman and CEO (left) and Mr. Hoang Ich Tuan – Business Development Director (right)

“In 2011, despite everything going well, we started receiving complaints about product quality. We discovered that our Chinese supplier, overwhelmed by orders, outsourced production without quality control, leading to issues. We questioned how we could maintain our competitive edge and differentiate ourselves if we continued as a trading company,” Mr. Vu Quang Huy shared.

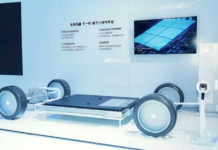

Currently, TEKCOM operates two factories with nearly 1,500 employees. The Binh Duong 1 factory focuses on construction formwork plywood with a capacity of 120,000 m³/year. The Binh Duong 2 factory produces RTA kitchen cabinets (100 containers/month) and interior plywood (96,000 m³/year).

Expanding exports to over 50 countries

TEKCOM exports to over 50 countries, focusing on Europe, the US, India, and ASEAN. Mr. Vu Quang Huy explained that each market has a unique strategy: Europe prioritizes compliant, value-added products; the US focuses on both products and components; India targets key clients; and ASEAN emphasizes standard products.

In 2012, TEKCOM began exporting to Turkey due to anti-dumping tariffs on Chinese products. From 2016 to 2018, the company expanded to South Korea, the Middle East, and began entering Europe and the US. To support growth, TEKCOM built the Binh Duong 2 factory to produce plywood for both construction and interiors.

Simultaneously, leveraging the US-China trade war, TEKCOM developed RTA kitchen cabinets. In 2020, the company invested in RTA cabinets for the US market, with a capacity of 75 containers/month.

TEKCOM’s factory

Regarding the journey of bringing “Made in Vietnam” products to the world, TEKCOM’s Chairman noted that in early export markets like Turkey and South Korea, Vietnamese plywood was seen as low-quality and inconsistent. These countries doubted Vietnamese companies’ ability to build compliant factories with traceability systems ensuring safety and social responsibility standards.

“They consistently ranked Vietnamese plywood below Chinese products and highly favored European, Russian, Indonesian, and Malaysian plywood. Seeing this, we were determined to change that perception,” Mr. Huy said.

TEKCOM’s Chairman emphasized that when selling products, Vietnamese companies not only carry their goods but also Vietnamese culture. More importantly, they aim to prove that Vietnamese businesses can meet high standards and create a difference in the international market.

High export ratio and the challenge of domestic market development

TEKCOM develops its domestic market by supplying construction plywood. Exports (direct and indirect) currently account for over 80% of its business amid global economic fluctuations.

“From a risk management perspective, TEKCOM believes that sustainable growth requires balancing domestic and export markets,” Mr. Vu Quang Huy stated.

Discussing future plans, Mr. Huy mentioned that the company is exploring opportunities in interior plywood, specifically kitchen cabinets, for applications in high-humidity, load-bearing environments. By focusing on the domestic market, TEKCOM aims to provide compliant, health-safe, and internationally quality products to Vietnamese consumers.

“In any market, there are both opportunities and challenges, potential and risks. With Vietnam’s real estate and construction sectors entering a growth cycle, this presents an opportunity for wood industry companies, including TEKCOM,” Mr. Huy added.

TEKCOM’s leadership also highlighted that to elevate Vietnam’s plywood industry, companies should focus on rubberwood, understand the market, invest in technology, and develop products through R&D. Mr. Huy noted that Vietnamese companies are evolving, and with strong efforts, they can create sustainable competitive advantages for Vietnam in the plywood sector.