Now, with just a few clicks, all indicators of production, business, inventory, and more are updated in real time. This is just a small slice of the grand picture of the ambitious digital transformation that the ‘giant’ of the Vietnamese steel industry is undertaking.

Impetus from the ‘Captain’ and the Revolution in Changing Mindsets

As a diversified corporation with a complex production ecosystem, Hoa Phat faced significant challenges in data management. Mr. Phan Ngoc Lam, Director of Information Technology (IT) of the Group, shared that the biggest difficulty was collecting and consolidating data from machinery and production lines.

“Typically, when there is a new investment project, manufacturing enterprises tend to focus on the technical and technological aspects of the line and pay little attention to the accompanying IT infrastructure and solutions for operation. In addition, enterprises often work with multiple machinery suppliers, leading to a situation where, over a long period, there are many lines of machinery and projects implemented, and the information flows in these systems are not linked and integrated,” said Mr. Lam.

Over the years, this has created countless “data silos,” where information is fragmented across departments and factories, making report consolidation a manual, time-consuming, and inconsistent process.

Since the end of 2019, Hoa Phat’s management has recognized these challenges and is determined to initiate a comprehensive digital transformation campaign.

“The will of the leaders, especially Chairman Tran Dinh Long, plays a decisive role,” emphasized Mr. Lam. The management not only formulates policies but also directly participates in closely directing the projects. The corporation’s vice president directly manages the digital transformation project.

However, the fire from the top also faced barriers from old habits. “When we started implementing, there was inevitable resistance. A long-time machine operator considered their job irreplaceable. When the company proceeded to automate the process, they feared losing their value or even their job. They might give reasons such as: the code is not uniform, this system is not similar to that system, so the robot cannot read it…,” Mr. Lam recalled.

To address this issue, Hoa Phat has continuously conducted training programs to help workers understand that their roles are not lost but elevated. Instead of doing repetitive manual work, they become supervisors, controllers, and process improvement agents. “Up to now, the units and factories themselves proactively propose digitization needs to us. That is the most significant success in terms of changing mindsets,” Mr. Lam proudly shared.

Constructing a ‘Digital Map’

While industries such as banking and finance focus on back-office processes in their digital transformation efforts, manufacturing enterprises like Hoa Phat must concentrate on operational transformation in addition to office management systems and back-office systems (such as human resources software, electronic offices, and electronic contracts).

The goal is to build a comprehensive architecture to link value chains, from ore mining, ironmaking, billet production, to steel rolling… The entire information cycle must be digitized into a “digital map” to control product quality and optimize the supply chain.

Hoa Phat’s strategy is divided into two distinct phases: The first phase involves hiring professional consultants to build a roadmap and comprehensive architecture. The second phase focuses on implementing quick-win projects based on the approved roadmap.

The transformation takes place on two parallel fronts. First, in Enterprise Management (Back-office), Hoa Phat integrates internal management systems such as human resources, electronic offices, and electronic contracts, solving the problem of data fragmentation among member companies.

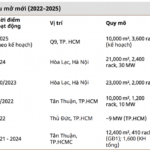

Second, in Core Business (Production), Hoa Phat Dung Quat Steel Joint Stock Company, the group’s flagship, has pioneered the implementation of numerous large-scale projects, including the SAP S/4HANA production management software, Salesforce CRM sales management system, port management system, automatic quality inspection sampling system, and Production Operation Data Center.

For a giant machine to transform, a robust IT infrastructure is indispensable. Hoa Phat has built an on-premise infrastructure combined with a multi-cloud outsourcing model from reputable providers.

For core production operation systems, latency and security are top priorities. Therefore, Hoa Phat prioritizes the use of on-premise infrastructure located at the group’s production operation data center.

For other applications, the corporation flexibly chooses suppliers to ensure redundancy and continuity. For example, for services serving global users, they prioritize global cloud providers. For domestic-focused services, they prefer local providers due to significantly lower costs.

The flexibility of cloud computing has made a distinct difference. Mr. Lam compared: “In the past, to expand a system, it could take us weeks or even months to go through the procedures, procure, and install servers. Now, with the cloud, it only takes 15 minutes to create a new virtual server.”

Viettel Solutions, one of Hoa Phat’s strategic technology partners, said: “In the process of Viettel providing services to Hoa Phat, such as transmission channels, Voffice, Warranty Management Software, and especially Cloud, we highly appreciate Hoa Phat’s vision and professionalism. They understand that for a large-scale manufacturing enterprise, digital transformation is not just about software but must start with a robust infrastructure.”

It is known that Viettel Cloud is currently one of the public cloud service and connection channel providers for Hoa Phat, supporting the deployment of IT infrastructure in the group’s digital transformation process.

Sweet Fruits

The results of the digital transformation at Hoa Phat are becoming increasingly evident. Mastering production technology based on digitized data has contributed to Hoa Phat’s successful production of hundreds of thousands of tons of high-tech and complex steel.

Notably, they produce high-quality steel coils for automotive tire cords and carcass plies, a product that only a few leading global corporations can manufacture. Recently, the successful production of EM12K grade steel used for welding rod cores, a product that only two enterprises in Vietnam can produce, immediately brought in orders of 3,000-5,000 tons per month.

Not only in the steel industry, but Hoa Phat Refrigeration Electrics Joint Stock Company also reaped success by applying the Lean Management system, increasing refrigerator production by 70%, confidently meeting export orders to the US market.

The most significant change is how Hoa Phat makes decisions. Instead of waiting, the management can now access an intelligent management reporting system where data from the operating systems are automatically pushed to a common data warehouse.

“Today, the boss wants to see the structure of a product in the total steel output. Tomorrow, he may want to view it from a different criterion. Our system can flexibly and multidimensionally adapt to instantly meet such demands,” Mr. Lam explained.

An essential competitive advantage for a steel enterprise in exporting is product traceability. With a bundle of steel exported to the US, Hoa Phat can now trace it back to the ore batch, shift, and quality of each process stage. This is a requirement of demanding markets, and without a digitized system, the group could not participate in the bidding process.

Notably, the systematic digitization and management of production and business data have contributed to the group’s ease of coordination and information provision in anti-dumping investigations in foreign markets. As a result, Hoa Phat’s hot-rolled steel coils were not subject to temporary anti-dumping duties by the EU, and most recently, Hoa Phat’s steel pipes were also not subject to anti-dumping duties when exported to the US market from May 5, 2025.

“Although positive results have been achieved, it is essential to emphasize that digital transformation is an ongoing journey that accompanies the enterprise’s development and never stops,” concluded Mr. Lam.

The Power of Persuasion: Crafting a Compelling Headline

“Legislative Body Urges Media to Intensify Propaganda on Central Resolution”

The Speaker emphasized that alongside amendments to the Press Law, the press needs to proactively embrace the digital transformation trend. He urged them to closely follow resolutions 57, 59, 66, and 68 of the Central Committee and take the lead in information dissemination within the context of comprehensive institutional reform.

Digital Transformation for Traditional Market Vendors: Embracing the Nation’s Digital Shift

Small business owners and traders of traditional markets are empowered with digital skills and e-commerce training. They are provided with access to advanced digital technology solutions and subsidized usage costs to expand their market reach.

“Empowering Small Businesses: From Operational Challenges to Digital Transformation.”

On the evening of June 12, the livestream event “Is Retail Management Easy?” hosted by ACB, attracted over 10,000 live viewers, garnered nearly 6,000 comments, and was shared hundreds of times within just 90 minutes of its broadcast. This overwhelming response highlights the keen interest in a topic that, though seemingly familiar, continues to pose challenges for business owners.

A Leading Corporation Seeks Partnership with Binh Duong for Urban Railway Development

The MiTAC Group, a renowned and diversified conglomerate, is eager to showcase its expertise in urban railway systems and other core competencies in Binh Duong. With a proven track record of success, MiTAC is confident in its ability to undertake and excel in projects within this vibrant province.