Recently, Vingroup announced the establishment of a new subsidiary named VinMetal, venturing into the metallurgy sector. The newly formed company boasts an investment capital of 10 trillion VND, with plans to set up a production facility in Vung Ang, Ha Tinh, targeting an initial capacity of 5 million tons annually.

VinMetal aims to produce not only construction-grade steel but also specialized steel for electric vehicles and high-speed transportation infrastructure, including body panels, rails, and structural components for bridges, ports, and railways. The company also has ambitions to export steel to regional markets.

Inside VinFast’s Ha Tinh factory.

Vingroup’s announcement highlights that VinFast and Vinhomes will be the primary beneficiaries of VinMetal’s output. Notably, automotive steel is a highly complex material, demanding stringent quality standards and specialized equipment for both production and quality control.

Automotive-Grade Steel Standards

For over a century, steel has been the backbone of the automotive industry. However, producing steel that meets the demands of modern vehicles presents one of the greatest challenges in metallurgy. Unlike construction steel, which primarily requires strength and cost-effectiveness, automotive steel must satisfy multiple criteria: high tensile strength, excellent formability, corrosion resistance, weldability, and a smooth surface suitable for painting.

A 2020 report by the American Iron and Steel Institute states that current automotive steel standards are “more complex than any other steel-using industry”, as this steel must withstand significant impacts, remain lightweight to reduce energy consumption, and maintain absolute uniformity to ensure structural safety.

Automotive Steel Requirements

An automobile can be likened to a mobile enclosure, meticulously designed to meet various structural criteria beyond mere load-bearing capacity.

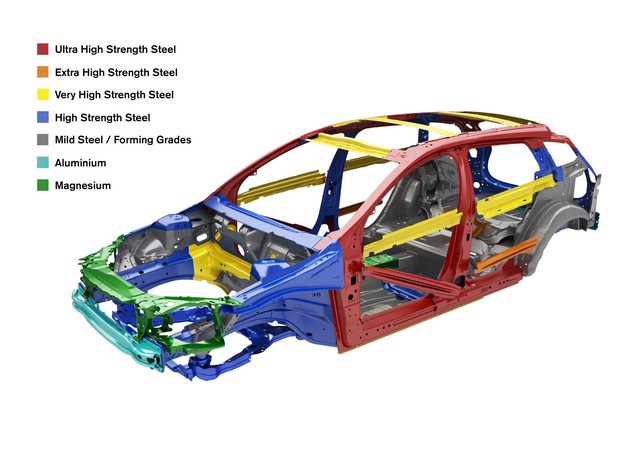

A vehicle is constructed from various steel types, balancing factors like rigidity, protection, and production costs.

Steel requirements vary depending on the vehicle component:

– Frames and pillars need high strength and crash energy absorption;

– Body panels and hoods require highly formable steel with a smooth surface finish;

– Floors and subframes demand fatigue-resistant and long-term corrosion-resistant steel.

According to a 2019 ScienceDirect article, automotive steel sheets must achieve tensile strengths between 500 and 1,500 MPa while maintaining over 20% elongation for formability. Even a 0.01% variation in carbon or manganese content can significantly alter mechanical properties.

Manufacturers must therefore strike a balance between strength and ductility, often conflicting attributes. As stated in the 2017 Springer journal article Metallurgical Perspectives on Advanced Sheet Steels for Automotive Applications, “Making automotive steel is the art of compromising between strength and formability.”

“A Small Mistake, A Big Consequence”

Steel production, especially for automotive applications, demands precision. Minor errors can drastically alter the final product’s quality.

Automotive steel production begins with smelting and refining at temperatures exceeding 1,600°C, followed by precise control of alloy composition, rolling speed, and cooling cycles, accurate to the second.

Workers inspect stamped panels at VinFast’s Hai Phong factory.

Advanced automotive steels like AHSS (Advanced High-Strength Steel) and UHSS (Ultra High-Strength Steel) result from multiphase metallurgy, combining ferrite, martensite, and bainite. Controlling the ratio and distribution of these phases determines the final properties.

A 2020 report from Oak Ridge National Laboratory notes that a “5°C deviation during annealing” can drastically alter the microstructure, making the steel brittle or difficult to form.

Consequently, modern production lines from companies like POSCO and Nippon Steel employ infrared sensors and real-time microstructure digitization to monitor each meter of steel sheet.

Forming Steel: A Complex Challenge

After achieving the desired mechanical properties, automotive steel must undergo body forming—a step that often puzzles engineers. According to a 2021 Springer study, steels with strengths above 1,000 MPa (Ultra High-Strength Steel, UHSS) are difficult to stamp or bend, prone to cracking, springback, and edge flaring.

To address this, automakers use hot stamping, heating steel to 900°C and simultaneously stamping and rapid cooling within the die. While this ensures precise forming, the dies must withstand extreme temperatures, increasing equipment costs by 3–5 times compared to cold stamping.

VinFast VF 5 chassis component.

Once produced and formed, the steel must pass rigorous testing to meet standards. The automotive steel testing process includes:

– Mechanical tests (tensile, compression, bending, impact);

– Salt spray corrosion, fatigue, and thermal deformation tests;

– Microstructural analysis using SEM and XRD;

– Batch-by-batch inspections to ensure consistency.

Due to these complexities in production, end-product requirements, and equipment needs, only a few global conglomerates can produce automotive steel at scale. Notable players include ArcelorMittal, POSCO, Nippon Steel, and Thyssenkrupp.

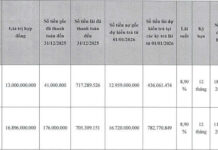

Vingroup Establishes Subsidiary with $430 Million Capital

Vingroup’s Board of Directors has approved the establishment of VinMetal, a new venture with a chartered capital of VND 10,000 billion. VinMetal will specialize in the production and trade of iron and steel, marking a significant expansion into the metals industry.

The 21-Year Odyssey of Billionaire Pham Nhat Vuong: Pursuing the World’s Tallest Sea-Reclaimed Tower

Vinhomes Green Paradise stands as the pinnacle of 2025’s real estate achievements, boasting a sprawling expanse three times the size of the former District 1 and a staggering investment of over $9 billion. To bring this visionary project to life, Vingroup dedicated 21 years to navigating intricate legal frameworks and meeting stringent environmental impact assessments, ensuring a development that redefines luxury and sustainability.

VinMetal Established with $4.3B Investment: Phạm Nhật Vượng Strengthens VinFast’s EV Supply Chain, Paving the Way for Higher Localization Rates

With a staggering $420 million investment in the establishment of VinMetal, Vingroup is revolutionizing the steel industry. This strategic move not only secures a vital steel supply for VinFast but also signifies a significant step towards increasing localization rates, empowering the company’s growth and self-sufficiency.

Proposed Construction of a Cross-Sea Bridge Connecting Can Gio and Vung Tau

Investors have recently proposed a feasibility study for a groundbreaking sea-crossing route connecting Cần Giờ to Bà Rịa Vũng Tàu, to be developed under a Build-Transfer (BT) model.