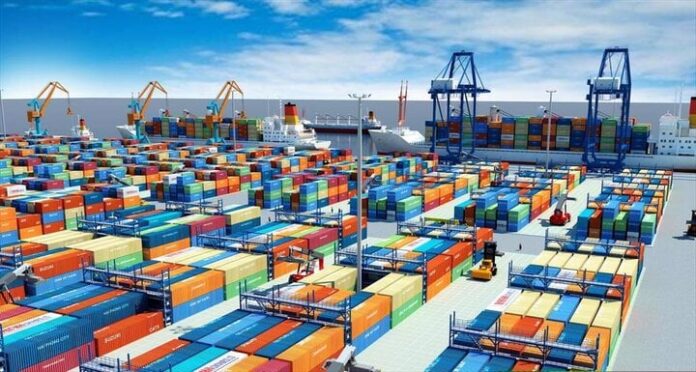

“Container Shortage and Shipping Crisis: A Global Challenge”

Vietnamese businesses are facing significant challenges due to the global container shortage and shipping crisis. The situation has led to delays in exporting goods and importing raw materials, resulting in late deliveries and penalties from partners.

According to a logistics expert, tensions in the Red Sea region following the Houthi attack on commercial vessels have forced shipping companies to avoid the Suez Canal and detour around the Cape of Good Hope. This detour adds 8-21 days to the transit time for ships traveling between Asia, the Middle East, and Europe, increasing shipping costs exponentially.

Adding to the problem, the shortage of empty containers experienced in 2020-2021 has resurfaced. The longer transit times mean a longer turnaround for returning containers, disrupting the balance of container supply and the entire supply chain.

The global container shortage and shipping crisis are causing significant disruptions. (Illustration: VASEP)

Typically, shipping containers take 1-3 months to complete a round trip from the export point to the import point and back. However, when this cycle is consistently prolonged over an extended period, it results in an imbalance in container availability and supply chain disruptions.

The longer routes and reduced shipping efficiency have also impacted the turnaround time for vessels, affecting the normal flow of maritime trade.

Mr. Tran Ngoc Hiep, Director of Hoang Hau Dragon Fruit Company (Binh Thuan), offers another perspective. He suggests that shipping companies are reluctant to lower their prices to avoid losses due to increased costs. As a result, they have reduced the number of voyages, opting for 5-6 trips instead of the usual 10. This could be a strategic move to create an artificial scarcity, making it easier to increase freight rates.

Delayed Ships, Costly Penalties

The leader of a seafood export company in Ho Chi Minh City captures the sentiment of many Vietnamese exporters facing this challenging situation.

“The shortage of ships has led to reduced voyages, increasing the risk of spoilage and quality issues. However, our biggest concern and the most significant financial impact come from penalties imposed by partners due to late deliveries,” he said.

Mr. Tran Huu Hau, Vice Secretary-General of the Vietnam Cashew Association, provides an example from the cashew industry. Vietnamese companies import nearly 3 million tons of raw cashews annually from African and Cambodian suppliers for processing and packaging before exporting them to European and American markets. When ships are delayed, and raw materials are not delivered on time, Vietnamese processors face challenges in meeting their export commitments, resulting in potential contract violations.

“In recent times, dozens of cashew companies have faced contract violations due to unavoidable circumstances, forcing them to pay penalties to their partners to maintain long-term business relationships,” Mr. Hau added.

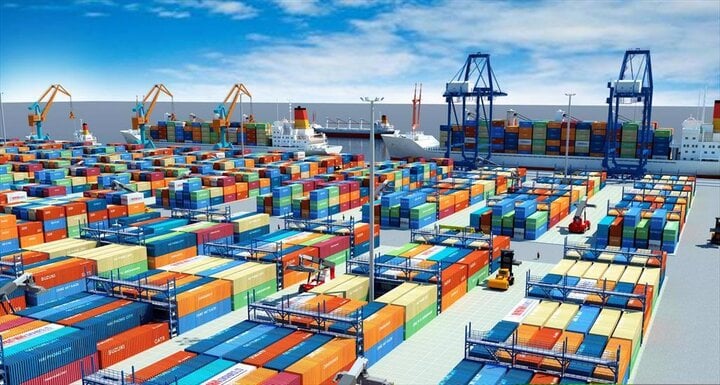

On the other hand, many Vietnamese companies with export orders are struggling to secure ships and containers due to the limited availability.

The container shortage has forced Vietnamese businesses to postpone export shipments or delay importing raw materials, resulting in late deliveries and penalties. (Illustration: Vietnam Government Portal)

Mr. Hau also mentioned that due to the prolonged shortage of empty containers, foreign shipping lines have unilaterally imposed various fees and surcharges on Vietnamese importers and exporters over the years, often without valid justification. This has prompted businesses to seek support from relevant authorities on multiple occasions.

Mr. Tran Ngoc Hiep emphasized the severe impact of the ship and container shortage on Vietnam’s import and export activities. He provided an example of fruit exporters who need to book ships in advance but face delays of several days, affecting their delivery timelines. Foreign importers of Vietnamese fruits may require the produce for festive seasons, but late shipments result in reduced consumption and potential deductions of 25-30% in the product’s value.

“With long-term partners, businesses can negotiate for lower deductions, but it is challenging to convince new partners,” Mr. Hiep added.

Despite the significant financial losses incurred by Vietnamese businesses due to late deliveries, shipping companies rarely take responsibility or compensate their customers for these delays.