In a conversation with the author, Mr. Thang argues that plastic should not be viewed solely as “waste” but rather as part of a circular economic value chain. Proper recycling processes transform post-consumer plastic into raw materials for industries like fashion, construction, technology, and household goods. Globally, many brands now incorporate recycled plastic into shoes, clothing, and accessories, while construction projects increasingly use recycled plastic to replace traditional materials, conserving forest resources and reducing costs.

In Vietnam, companies such as Stavian, Duy Tan, and An Phat have heavily invested in recycling technology and collection systems, laying the groundwork for a circular economy in the plastics sector. These efforts reflect a shift from traditional manufacturing toward sustainable practices, aligning with global trends.

Inside Duy Tan Plastic Recycling Corporation’s recycled plastic pellet production facility

|

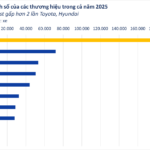

According to statistics, Vietnam’s plastics industry generated $31.5 billion in revenue in 2024, with exports nearing $10 billion. In the first seven months of 2025 alone, the country imported 5.55 million tons of raw plastic materials worth over $7.3 billion, a significant increase year-over-year. Vietnamese plastic products are now present in more than 190 countries, including demanding markets like the U.S., EU, and Japan.

Mr. Thang emphasizes that plastic has a lower carbon footprint than many traditional materials, making it ideal for fuel-efficient, low-emission transportation sectors. Rapid urbanization in Vietnam has also increased demand for plastic in construction. Additionally, the rise of e-commerce and a growing middle class has boosted consumption of plastic household items, packaging, and wrapping materials.

As the world prioritizes sustainability, investing in recycled plastics and bio-based materials has become imperative rather than optional. According to the Association’s Chairman, this shift not only expands export market opportunities but also enhances Vietnam’s national brand value.

“Plastic isn’t the problem—it’s part of the solution when used and recycled responsibly. Only through collaboration among policymakers, businesses, and consumers in product design, source-separated waste collection, and efficient recycling can the plastics industry truly contribute to a green, sustainable future,” Mr. Thang remarked.

Mr. Dinh Duc Thang – Chairman of the Vietnam Plastics Association

|

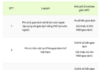

At the 2025 International Plastics and Rubber Exhibition (Vinaplast), the Association highlighted persistent barriers to recycling investment. Ms. Huynh Thi My, Vice Chairwoman, noted that many companies face challenges securing land or navigating industrial zone procedures due to pollution concerns associated with recycling.

Collection efforts also remain inefficient. Vietnam consumes 4-5 million tons of plastic annually, yet most waste is not managed properly, with significant amounts still burned or landfilled. The quality of collected plastic for recycling also varies widely.

In response, the Vietnam Plastics Association has urged the government to establish dedicated circular economy industrial zones to address legal bottlenecks and expand extended producer responsibility (EPR) mechanisms to more product categories. These measures, Ms. My believes, will create an enabling environment for businesses to invest strategically in recycling, meet stringent international standards, and move Vietnam’s plastics industry closer to its sustainable development goals.

Vietnam’s Plastics Industry Faces Major Collection and Recycling Challenges

– 09:02 23/09/2025