Post-COVID-19 Challenges and the Urgency of Digital Transformation for Vietnamese Manufacturing Enterprises

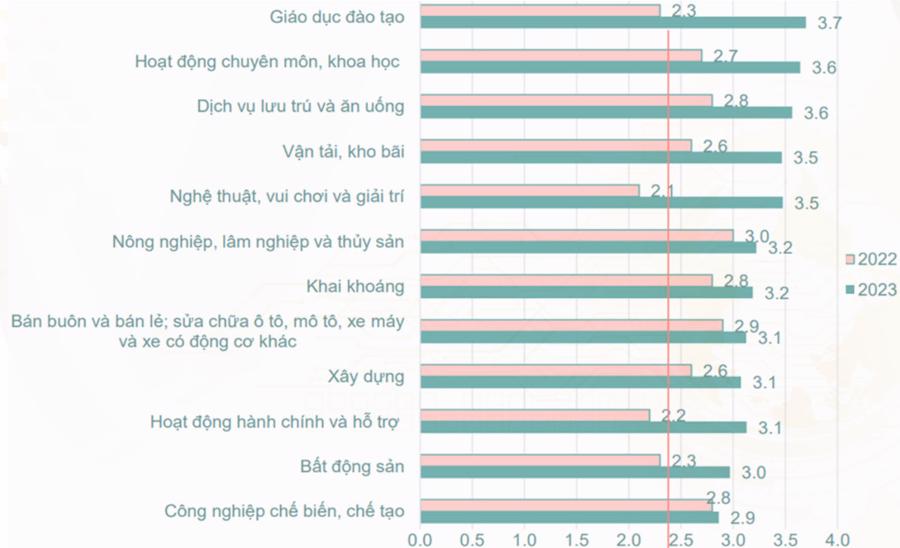

The COVID-19 pandemic has had a severe impact on Vietnam’s economy, particularly affecting many industries and businesses. Production and business activities have faced disruptions due to supply chain disruptions, leading to shortages or interruptions in raw material supplies. Exports have declined significantly, necessitating an accelerated transition to digitalization, especially for manufacturing enterprises.

Challenges Remain

At a workshop on “Enhancing the Competitiveness of Manufacturing Enterprises through Cost-Saving and Resource Optimization Solutions Using Technology,” organized by the Vietnam Chamber of Commerce and Industry (VCCI), Mr. Nguyen Trung Thuc, Deputy Director and Acting Director of VCCI’s Enterprise Information Technology Institute, emphasized that digital transformation involves not only technological advancements but also changes in management, operations, marketing, and promotion.

According to Mr. Thuc, along with government investment, there is a need for socialized solutions to mobilize domestic and international resources to invest in the development of digital technology in the manufacturing sector. This will ensure that the digital transformation process is focused, effective, and avoids duplication and waste.

Digital transformation should prioritize citizens and businesses as the central focus, empowering them and providing services that meet their needs effectively.

Worldwide, digital transformation in manufacturing is progressing at an accelerated pace. The integration of advanced technologies provides significant benefits for businesses, changing workforce mindsets, reducing costs, and optimizing resources.

Despite these advancements, Mr. Thuc believes that Vietnamese manufacturing enterprises face ongoing challenges in a rapidly changing technological landscape and intensified competition.

Key Challenges

Financial Constraints: Digital transformation requires significant investment in process, system, and workforce changes, demanding a substantial budget for comprehensive and holistic implementation.

Mindset Shift: Digital transformation is not solely about technology but requires a mindset shift within organizations. Even with advanced systems, traditional thinking can hinder the effective utilization and exploitation of technology.

Technology Selection: Choosing the appropriate technology for a specific enterprise is a crucial challenge. With the rapid development of AI, Machine Learning, IoT, 3D modeling, and Cloud, finding the optimal solution can be daunting.

Dr. Tran Quy, Director of the Vietnam Digital Economy Development Institute, concurs, stating that the most significant challenge in digital transformation is changing ingrained habits. He emphasizes that recognition and accurate understanding are paramount for successful transformation.

Experiences and Practices

At the workshop, Mr. Takei Daisuke, CEO of CADDI Vietnam, shared Japan’s experience, noting that 60-70% of enterprises in the country have embarked on digital transformation.

“One of the driving forces for Japanese businesses to adopt digitalization is the shrinking youth population and a shortage of labor,” Mr. Daisuke explained. “As a result, companies are forced to transform their work practices, utilizing more technology and automation.”

In addition, the increasingly competitive global market demands that Japanese companies accelerate digital transformation. Through technology adoption, Japanese engineers have accelerated the design process, reducing the time required to create new blueprints by 50-60% and optimizing procurement.

From the perspective of Vietnamese manufacturing enterprises, Mr. Do Phuoc Tong, Chairman of the Ho Chi Minh City Mechanical – Electrical Enterprises Association, shared his experience as a machinery entrepreneur who has been implementing digital transformation for over a decade. However, he acknowledges that the transformation process is ongoing and constantly evolving.

“Digital transformation must begin with leadership commitment and determination. There must be a clear understanding of the benefits it will bring to the company. However, many businesses remain apprehensive due to the risks associated with the transition,” Mr. Tong stated.

Mr. Tong also highlights the challenge posed by market volatility, recognizing that digital transformation alone cannot fully mitigate market fluctuations. The key for businesses is to optimize human resources, finances, and technology to adapt effectively.

Dr. Tran Quy advises businesses to proactively seek out and utilize support programs and packages, particularly those related to fiscal incentives, tax breaks, and financial assistance. He also emphasizes the importance of diversifying capital sources, markets, supply chain partners, and being proactive in production and business operations. During the implementation of digital transformation strategies, attention must be paid to enterprise adaptability and effective risk management, including legal, financial, and security aspects.

“Manufacturing enterprises should seize opportunities to enhance relationships with developed countries in digital transformation, deepening cooperation ties,” Dr. Tran Quy concludes.