Chị Đỗ Hồng Hạnh, CEO và Co-Founder of Buyo Bioplastics, is a former chemistry major but chose a different path when she entered university. She studied International Economics at the Foreign Trade University in Hanoi and later earned a Master’s degree in Business Administration at the University of Southern California. Throughout her career, she has held several important roles such as Representative at Ban Viet Securities Investment Fund Management Joint Stock Company, Economic Growth Specialist at USAID Vietnam, National Representative of the Asian Competitiveness Institute in Vietnam, and Business Development Director at Esquel Group. In 2021, with a desire to do something beneficial for the community, Hạnh invited her high school classmate, Dr. Trịnh Hòa, an environmental engineer, to join her project. Afterwards, Buyo’s founding team expanded to 4 members when two more of Hòa’s classmates from the US, who are also PhD holders, joined.

Why did she decide to start a business in the field of biodegradable plastics in Vietnam?

Buyo was established in September 2022, but we had the idea about a year ago. The idea for Buyo came from our clear awareness of the plastic waste pollution problem, which is one of the greatest challenges that countries are facing, especially in Vietnam – a country that is facing one of the world’s leading plastic pollution problems.

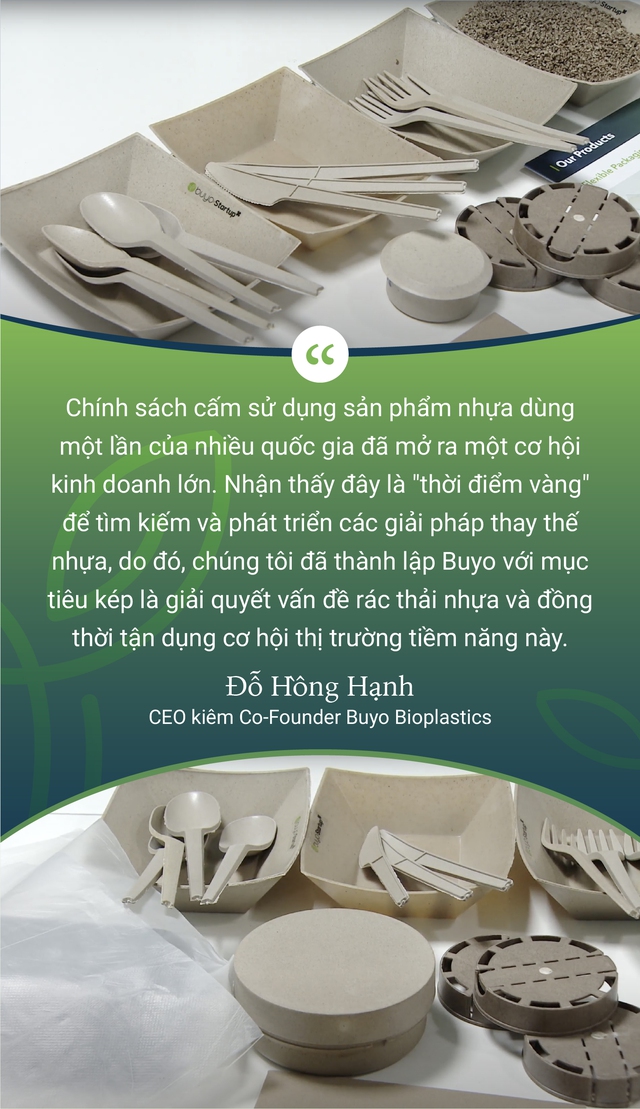

The banning of single-use plastic products by many countries has created a great business opportunity. We saw this as a “golden opportunity” to seek and develop alternative solutions to plastic. Therefore, we established Buyo with the dual goal of addressing the plastic waste problem while taking advantage of this potential market.

The bioplastics industry in Vietnam is not new and there are many businesses involved. How do you evaluate the development opportunities of Buyo in this market?

Not only Vietnamese businesses, but many foreign businesses from countries such as China and South Korea are also strong in this field and have been operating for many years. Each side has its own advantages. Buyo offers a new and more comprehensive solution compared to previous solutions.

Most existing solutions mainly use starch-based materials such as rice, cassava, and corn. However, using starch, a food source for human consumption, to produce plastic presents contradictions and affects food security. Bioplastic products made from starch also have limitations such as being prone to swelling when in contact with water and low durability.

Buyo’s products are created using new technology that utilizes biowaste as the raw material, resulting in biodegradable bioplastics without the limitations of previous products. The products are completely organic, not mixed with chemical or petroleum-based plastics, and do not contain microplastics, ensuring safety for health. Buyo’s products can completely biodegrade in natural conditions, without the need for incineration, just burial in the ground, and will completely decompose after about a year. This helps minimize greenhouse gases by reducing organic waste discharged into the environment. In addition, during the production process, Buyo focuses on using renewable energy and reusing water.

With such outstanding product advantages, we believe that there are still many opportunities for Buyo to expand and develop.

Why does Buyo use biowaste as the raw material instead of other materials?

Initially, we did not immediately think of using biowaste and considered many other types of raw materials, including fruit peels. Since Vietnam is a large exporter of fruit, there is a considerable amount of fruit peels and spoiled fruits. However, after many experiments with various raw materials, we selected the most feasible material that ensures both quality and quantity.

In the lab, it was easy to create products, but when applied to industrial production, it was a different story. After a meticulous selection process, we realized that biowaste is the most suitable raw material, not only technically but also in terms of providing stable quantities and consistent quality. And importantly, the biowaste obtained is a single source, without the need for sorting or impurities. This helps standardize the production process and reduce costs.

A common challenge for green startups, such as biodegradable bioplastics, is still facing the challenges of production costs and consumer awareness. What about Buyo?

That also applies to Buyo. Biodegradable bioplastics from biowaste are still a relatively new material, so the biggest challenge for us is to communicate to the market and customers, help them understand the special features and benefits of the product compared to other products on the market. Furthermore, as a material and technology company, while our scale of production is still limited and has not reached a large scale that can help reduce costs, we are making efforts to make our products more cost-competitive, enabling them to be on par with products made from sugarcane or paper for consumer use.

How is the expansion plan to scale up production and reduce the cost of Buyo’s products going?

Buyo currently has a factory in Ho Chi Minh City, and the plan for the coming year is to expand production scale by building a new factory that is ten times larger than the current one.

The company serves two main customer groups: multinational corporations and large enterprises primarily in Vietnam and Asia. Buyo continues to plan to expand to international markets while building a distribution network in major markets such as the US and Europe. In the coming months, I will be visiting these markets to conduct research and expand business operations.

This year, Buyo will raise the next round of funding, Series A, to expand its production scale and introduce more products to the market. Since its inception, Buyo has raised around $750,000 in funding.

Currently, Buyo focuses on producing various packaging products, including plates, knives, spoons, forks, boxes, bottles, as well as various wrapping films and bags for household use. In the medium term, the company plans to expand into the industrial sector. In the long term, Buyo’s goal is not limited to bioplastics but aims to become a provider of various biobased materials. We are currently conducting research and development (R&D) activities to create new biobased materials for the medical, pharmaceutical, and cosmetic industries.

Before starting Buyo, you were the Business Development Director for a textile and garment corporation. Why did you decide to give up that job and start again with Buyo?

I have been working at large companies for quite a long time and have experienced many different job fields. Therefore, I feel that I have a clear understanding of the working environment there and there is not much room for learning. Currently, I want to challenge myself with more challenging jobs.

When working at a large company, everything has already been established for a long time, with clear standards and systems. This facilitates management work because there is a strong support team in terms of both finance and personnel. On the other hand, in a startup environment, due to limited financial resources, the number of employees that can be hired is also limited, which requires the organization to operate in a lean and agile manner, and managers have to take on multiple positions. At present, I am concurrently serving as the CFO, HR director, operations director, and sales director. Furthermore, a startup also has to accept high uncertainties and risks; unlike large companies with regular budgets from the group, startups do not have a fixed budget and require flexible adaptation to any situation that may arise.

Another important point is that I have seen the problem of plastic waste, a big social problem, and have the opportunity to change it and build a company that is not only for profit but also aims to solve a major social issue.

What are Buyo’s goals for the near future?

Our lofty goal, as well as our biggest goal, is to provide a new and comprehensive solution that can address a major global issue. This goal is not only in terms of science and technology but also socially.

From an economic perspective, our short-term goal is rapid growth in scale, bringing Vietnamese deeptech products and brands to the world, and gaining recognition from international partners, especially multinational corporations. This is not only a source of pride for ourselves but also a motivation for our entire team.